The influence on the building structures of buildings and structures of various liquids in the form of precipitation, groundwater, and man-made water is perhaps the most aggressive type of influence. To protect, as well as increase service life and operational reliability, what is called waterproofing is used.

It is arranged in two common ways:

- Coating or painting, when applied in liquid form to the internal or external surface of the structure, and after setting, form a reliable waterproof thin-film coating or rubber-like polymer cover, up to 5 millimeters thick. For example, it could be polyurea, which is sprayed onto the protected surface using compressed air.

- Pasting, when used on horizontal, vertical or inclined surfaces, a protective layer of flexible sheet panels or roofing felt rolls is installed. Traditional cardboard in roofing felt has long been replaced with a reinforcing base - polymer or fiberglass.

In this article, we will look at what adhesive water protection is, its options, the correct design, and also its use.

Which roofing material is best to use for foundation waterproofing?

In this article we will talk about which roofing material is best used for waterproofing foundations. Firstly, it is necessary to explain why the use of welded rolled material is preferable to coating and spraying technology. The fact is that under construction site conditions it is extremely difficult to control the thickness of the application of liquid materials. In some places the layer will be thicker, and in others much thinner.

Mastics are applied in thin layers. This is necessary so that the solvent included in the liquid waterproofing can freely evaporate from the material. Otherwise, defects may appear on the waterproofing layer.

The use of built-up materials of the Euroruberoid type guarantees an equal thickness of application over the entire surface of the foundation. With a continuous sticker of the waterproofing layer, a small defect is localized in the area where it appears and does not have a serious impact on the reliability of the entire waterproofing.

But what brands of roofing felt are preferable to use for gluing the foundation slab?

Choice of coverage

To use this material as a lining, it is recommended to choose the brands PM 350, PM 420, PM 500, but for the outer layer of the roof, RK 420 or RK 500 are suitable. Fused types of material are especially popular now.

Among the manufacturers we can note the following:

Roll materials TechnoNikol

There are other manufacturers of roofing felt. When purchasing, it is best to take into account, first of all, those companies that have existed for many years. Such manufacturers value their reputation and are unlikely to produce low-quality material. Unfortunately, there is always a risk of running into a fake.

When choosing a material, you should pay attention to the following aspects:

- integrity of the canvas;

- absence of kinks, cracks;

- roll density;

- quality of base impregnation (determined by the color in the section - it should be black with a slight brownish tint).

On a note! Tears in the material are allowed only at the edges of the roll, but they should not be longer than 30 mm.

Materials that cannot be used for waterproofing foundations.

It is strictly not recommended to fuse materials based on oxidized bitumen. This is due to the fact that these materials lose their characteristics with minor chemical exposure. As a result, roofing felt becomes more fragile and cannot withstand groundwater pressure. It is also prohibited to paste the foundation with rolls of fiberglass and fiberglass as a base, since they are not chemically resistant. And this significantly affects the service life of the waterproofing layer. Let's list specific brands: roofing felt, hydroisol, Bikrost, Linokrom.

Using roll-up waterproofing

To extend the service life of the building’s foundation from destruction by water, reliable roll waterproofing is installed.

This universal material has many advantages: - easy to install, no special skills or experience required; — available in various configurations and sizes; - reasonable price. The material is used to protect walls, the foundation of a house, roofing, hydraulic structures and water supply networks.

Below we will consider the main types and classes of rolled waterproofing, a description of the parameters of raw materials, markings, installation techniques, features and advantages of the material.

Waterproofing helps prevent destructive processes in materials of buildings for various purposes. The barrier protects the access of the humid environment to the structure of the main material of the building and significantly increases the overall service life of the building.

Brands of roofing felt recommended for use when gluing foundations.

To protect the foundation, rolls are used as the base of which polyester is used. It is chemically inert and will last as long as possible. The material on polyester is marked with the letter “E”. For example, EPP. It is recommended to use Tekhnoelast polymer-bitumen roofing felt as a reliable grade of material for waterproofing concrete foundations of both strip and monolithic types.

- The service life of such euroroofing material reaches 60 years.

- Chemically resistant.

- Capable of withstanding enormous water pressure of 0.2 MPa - this is water pressure at a depth of 20 meters.

- The production technology allows waterproofing to be carried out in both 2 layers and 1 layer.

Interested in the price of performing such work? Call us and we will tell you more details.

Rolled waterproofing for floors

The floor of a private home or commercial building also requires high-quality waterproofing. For this purpose, roll membranes of various types can be used.

Recommendation: It is recommended to use premium built-up sheets for concrete floors, and decking and adhesive types of insulation for wooden floors.

When installing roll and other floor waterproofing, you need to follow several basic steps:

- Prepare surfaces in terms of cleaning them from dust and dirt;

- At the floor-to-wall junctions, it is necessary to make a small plinth from CPPS or a special tape for a smooth transition of insulation from horizontal to vertical;

- Apply a bitumen primer to the surface to improve welding and gluing of sheet rolls with a base;

- Install the insulating coating in 1-2 layers, so that the second layer overlaps the seams of the previous one.

What is roofing felt and why is it needed ↑

Roofing felt is made from roofing cardboard, impregnated with fusible bitumen and coated on both sides with refractory bitumen. To prevent the roll into which the roofing material is rolled from sticking together, the surface is treated with talc. The material can also be coated on one side with a protective coating of mineral chips, which increases its resistance to ultraviolet rays and mechanical wear resistance. Designed for waterproofing building structures, used in roofing, to protect underground floors and building foundations from moisture.

Storage and transportation rules

When storing rolled fused waterproofing, a number of rules must be observed - the rolls must be installed in a vertical position, access to moisture and direct sunlight must be blocked. The heat source should be more than a meter away from the rolls.

It is recommended to store rolled waterproofing in a vertical position.

Waterproofing material is transported in covered transport, preferably in a vertical state. When installed vertically, the number of rows in height is no more than two. For horizontal transportation, no more than five rolls in height are allowed.

Brands and characteristics ↑

GOST 10923-93, in accordance with which roofing felt is produced, divides products into several grades, differing in the type of base (cardboard) and the nature of the topping.

In addition to those specified in GOST, you can find other brands of roofing felt on sale, manufactured according to the manufacturer’s specifications. Let's decipher the main designations found in product names:

- The first letter is always “P” - roofing material.

- The second symbol is the type of material: “K” - roofing; "P" - lining.

- The third letter is the type of topping: “P” - dusty (talc); “K” - coarse-grained; "M" - fine grain; “C” is a scaly coating (usually mica; “C” is color-resistant. The letter “E” means that the roofing material not only has a coating, but has increased elasticity and frost resistance.

The numbers following the letter designation indicate the brand of roofing cardboard. The higher the number, the denser the cardboard, the greater the thickness of the roofing material and, accordingly, the stronger the material.

The width of roofing felt is 1000 mm, but some factories produce rolls with a width of 1025 and 1050 mm. Tolerance - 5 mm. It is possible to produce rolls of non-standard width. The length of rolls of the RKK brand is 10 m, RKCh and RKP - 15 m, RPP - 20 m. The thickness is not standardized, the weight in GOST is given for reference.

How to deal with the markings?

Each roll of coating has its own marking, which will indicate the intended use of the material, its features and indicators. It is applied to the reverse side of the coating or to the label and consists of numbers and letters. Let's try to figure out how to read it correctly.

So, the letters are deciphered as follows:

- the first P means what kind of material it is - it’s not hard to guess that it’s roofing felt;

- next comes the letter K or P, which indicates the scope of use of the coating, that is, P is lining, and K is roofing material;

- the third letter in the marking - K, P, M or Ch - informs the buyer about the type of sprinkle. For example, scaly, dusty, coarse-grained or fine-grained layer;

- the three-digit number indicates the density of the cardboard. For example, 350 g/m2. The indicator reports that there are about 350 g of cardboard base per 1 m2.

There may be another letter at the end of the marking. For example, E will tell the buyer that the material is stretchy, and C will indicate colored sprinkles. The letter C indicates that the roofing material is based not on cardboard, but on fiberglass.

On a note! If the roofing material is colored, then the designation C can also appear at the beginning of the marking, immediately after the designation P - roofing material.

Positive and negative aspects of the material ↑

Ruberoid has almost 100% moisture resistance, which allows it to be successfully used for waterproofing in construction. Just a few decades ago, this type of insulation was the main, if not the only, available for flat roofs and foundations. But today, archaic roofing felt has been largely replaced by more advanced types of rolled bitumen-polymer waterproofing, made on the basis of fiberglass or fiberglass mesh.

Polymer additives modify bitumen, giving it increased elasticity, frost resistance, and increase resistance to ultraviolet radiation. A roof waterproofed using the latest roofing felt analogues will last 15-50 years, depending on the type of material used. A roof covered with traditional roofing felt, in climatic conditions, will take 8 years on average, and in the northern or southern regions - even earlier.

The only competitive advantage of roofing felt is its relatively low price. It is no longer used in large-scale construction of critical buildings, having given way to more expensive but high-quality insulation. But cash-strapped private developers and builders continue to use roofing felt for the construction of temporary structures, guided solely by its low cost.

Let us emphasize that roofing felt and modern polymer-bitumen roll waterproofing materials (bipol, linokrom, technoelast, etc.) are not the same thing. The materials have very different characteristics (mainly in terms of durability), although they are similar in appearance and are installed using the same technology.

Technology for performing adhesive waterproofing

The adhesive waterproofing is installed according to the method and sequence depending on the type of preparation of the surface to be protected:

- for bitumen-based materials, glue in the form of molten bitumen is most likely suitable;

- for materials based on polymer resins and synthetic rubbers - cold-curing mastics.

Horizontal surface

The horizontal level of building planes - floors, ceilings, flat roofs, balcony cantilever slabs - is protected by rolling, fusing or gluing rolls of the selected material.

Horizontal waterproofing of walls is performed as a barrier. It separates the reinforced concrete monolithic base from the boundary above which the wall is located to prevent the filtration of ground moisture into it.

In this case, the glue application zone can be continuous or sparse, in the form of alternating stripes. In some cases, individual fragments of a waterproofing carpet can be glued together in places of overlap and not contact the protected surface, allowing them to move freely relative to each other due to thermal expansion or other types of deformations.

Horizontal waterproofing of the fused type is often used to protect large surfaces , for example, flat roofs of multi-storey buildings or industrial buildings, workshop floors, as well as floors of shopping or cultural and entertainment centers.

Vertical surface

When waterproofing vertical surfaces (walls) using adhesive materials, it is necessary to take into account the ability of the adhesive compositions to prevent the sheet roll paintings used from sliding under the influence of their own weight until the mastic sets. This property is called thixotropy.

The best way to cope with this is with ordinary molten bitumen, used in the form of mastic or melting the working surface of the insulating protection. When using it on a wall, the vertical level of the rolled or flat waterproofing sheet will need to be held for no more than one minute.

However, this method is not suitable for all types of waterproofing. Vertical adhesive waterproofing based on polymer or synthetic rubbers cannot always withstand high temperatures, it can be strictly contraindicated, in this case it is necessary to use glue and cold-curing mastics.

Inclined surface

The installation of adhesive waterproofing on inclined surfaces is not much different from vertical or horizontal waterproofing.

However, from the point of view of ease of installation and subsequent operation, you can adhere to the following rules:

- At an angle of inclination above 45 degrees, use bitumen-based waterproofing together with hot-curing mastic.

- If the angle is less than 45 degrees, use bitumen-polymer, polymer or rubber waterproofing together with the cold adhesive recommended for them.

Application in construction and in the countryside ↑

Briefly about the features of using roofing felt: how to cover a garage roof with roofing felt with your own hands, isolate the foundation from moisture, etc.

Flat roofs ↑

The waterproofing coating of flat roofs is carried out by fusing several layers of rolled waterproofing. By the way, a roof is considered flat if its slope does not exceed 15 ºС. There should be at least two layers: lower and upper, open to all winds, sun and precipitation. But the roof will last longer if there are three layers. Which roofing felt is best for a roof? For one or two lower layers, the RKP brand is used, for the top - RKK, RKTs, RKCH. In harsh climatic conditions - RKE. The coating protects the surface from mechanical influences (moderate walking on the roof is allowed) and reduces the destructive effects of UV rays on bitumen. The thickness of the roofing material intended for the lower layers will be 0.5-1 mm, the upper - 1.5-2.5 mm.

The concrete base (floor slab, screed) should first be coated with a bitumen primer. After the primer has been absorbed and dried after a few hours, you can begin fusing the rolls. The area intended for gluing one strip is completely covered with bitumen mastic and, without waiting for it to dry, the roll is rolled out. It is necessary to ensure that the entire surface is glued; air bubbles are not allowed. Then they begin to gradually heat the roofing material with a gas burner or a blowtorch, rolling the roll to the base with a special roller or wooden mop. It is necessary to heat the bitumen to such an extent that, having softened, it not only sticks to the mastic, but “melts”.

This technology provides much better adhesion of the material. At the same time, roofing felt cannot be overheated, otherwise it will become brittle and the service life of the material will noticeably decrease. The adjacent roll is fused with an overlap of 10 cm. A second lining layer, if provided, is placed on top of the first layer. The last layer is fused in the same way, with a protective coating.

If the garage roof made of roofing felt does not rest on a concrete slab, but on a wooden sheathing, the first layer is not fused, but nailed to the boards with special roofing nails with an enlarged head. Their step should be quite frequent, about 25 cm.

Pitched roofs ↑

A pitched roofing material can only be considered as a temporary option. In any case, material designed specifically for pitched roofs (slate, ondulin, metal tiles, etc.) will last an order of magnitude longer. If the temporary roofing is designed for a season, the rolls are rolled out over the sheathing and secured on top with slats to the rafters. If it is necessary to install a roof for several years, the first layer is nailed down, and the second layer, with sprinkles, is glued onto the mastic with an overlap.

Until recently, roofing felt was used as a drainage and anti-wind layer, placing it under slate in pitched roofs. Today, such use of the material is limited only to ventilated attics of non-residential buildings. In other cases, it gave way to more advanced and environmentally friendly moisture-removing under-roof films.

Foundations and walls of basements ↑

The technology for fusing roll waterproofing on the basement of a building is the same as on the roof. It’s just more difficult to work with the material, because you have to process vertical surfaces. When constructing foundations and basements, it is necessary to ensure that the insulation is continuous, without gaps. If there is an uninsulated place somewhere, moisture will inevitably penetrate there, the concrete will become damp and the internal pressure of water will begin to gradually tear the rolls away from the surface. It should not be forgotten that, in addition to vertical insulation of the basement walls, they must be waterproofed from below, from the foundation tape. The rough screed of the basement floor is also subject to insulation. For these purposes, you can use rolls of both the RKP brand and the less expensive RPP. All sections of rolled insulation: walls, foundation base and floors must be connected (fused) to each other.

Waterproofing floors ↑

In addition to floors in basements, floors on the floors above must also be insulated from moisture. At a minimum, waterproofing should be done in wet areas: bathrooms and showers. It protects the underlying floors from water penetration. The rolls are placed on the wall to a height of about 10 cm. The roofing material is glued to the floor slab or rough screed, and a finishing tile is made on top, on which the facing tiles are laid. It is recommended to insulate against moisture under natural parquet to prevent moisture from penetrating into the wood from the floor slabs. In this case, the non-ecological bitumen material is also covered with a finishing screed.

Dacha farming ↑

For a thrifty summer resident, everything will work. Used roofing material removed from the roof of a garage or barn can replace a ground covering film, protecting the soil and plant roots from drying out and preventing the growth of weeds. A rolled sheet dug vertically into the ground will serve as a limiter against the unwanted spread of the root system of raspberries and other bushes that actively reproduce vegetatively. You can use old cardboard impregnated with bitumen to light a stove. Of course, all this is very unecological. But it's free.

When working with roll waterproofing, especially using fusion technology, you should be extremely careful and careful: the technology is potentially fire hazardous. If you lack the skill, it is better not to take on such a task yourself, but to entrust the work to professionals.

Waterproofing the first floor of the apartment. Features of waterproofing

Despite the fact that at first glance, the technology for protecting the surface seems simple, in fact, waterproofing a concrete floor, especially the first floor, has quite a lot of features. Among which the following can be noted:

- a drainage system must be installed in a country house; without it, all waterproofing manipulations will be doomed to failure;

- protection of the floor of the first floor must necessarily take into account the likely shrinkage of the structure;

- waterproofing the concrete floor of a bathhouse requires the use of the most reliable materials, which, with constant contact with a humid environment, will not lose their original qualities;

- the protection of the garage base must have such qualities as frost resistance, since heating in such rooms is rare, and the floor will definitely freeze;

- Waterproofing of the concrete floor of the basement is carried out in several layers, since this part of the structure will be constantly exposed to the negative effects of groundwater.

Let us consider in more detail what subtleties need to be taken into account when protecting certain rooms from moisture.

Waterproofing a concrete floor in a bathroom

Waterproofing in the bathroom is a mandatory procedure when carrying out renovations and is carried out immediately before laying the flooring and installing plumbing. In the event of a water leak, it will not give the water a chance to penetrate the ceiling, disrupt the structure of the structure and allow unpleasant consequences.

A protective coating, usually a penetrating or coating composition, is applied to the floor and bottom of walls up to 20 centimeters high in 2-3 layers. Additionally, waterproofing is done on the wall where the bathtub will be installed.

Waterproofing a concrete floor in a bathhouse

The bathhouse is significantly different from other buildings, so protection from moisture in this case will also be different than standard waterproofing of the floor in a private house or apartment. The first thing that needs to be done is to arrange a high-quality drainage in the room and drainage of water from the building (drainage), and only then can you proceed directly to the insulation.

As a rule, waterproofing in a bathhouse, provided that the floor is made of concrete, is carried out using coating mastics and pasting the base with rolled materials.

Initially, the surface is leveled, defects (cracks, potholes, etc.) are filled with cement mortar. After this, you can begin treating the floor with bitumen or polymer mastics, doing this in several layers, each of which is applied perpendicular to the previous one.

Pasting with roll materials must be carried out on the walls, the waterproofing joints are sealed.

Another option for floor protection is penetrating insulation, which penetrates deep into the pores of concrete, strengthening it, forming a reliable and durable moisture barrier.

Waterproofing a concrete floor in a garage

Waterproofing the garage floor is usually done before the screed is poured.

Since in this case it is very important to protect the soil from the concrete base of the building (similar to how waterproofing a concrete floor is carried out over the ground of the first floor). The most affordable materials will be high-density PVC film, adhesive and weld-on insulation, and polymer membranes. If the screed has already been filled, and the room needs waterproofing, then experts recommend using bitumen mastic, which is applied in several layers

Also a good option would be a penetrating mixture that penetrates deeply into the concrete structure and makes it resistant to moisture. The choice of waterproofing is determined in each case individually, based on the condition of the room, groundwater level and other parameters

If the screed has already been poured, and the room needs waterproofing, then experts recommend using bitumen mastic, which is applied in several layers. Also a good option would be a penetrating mixture that penetrates deeply into the concrete structure and makes it resistant to moisture. The choice of waterproofing is determined in each case individually, based on the condition of the room, groundwater level and other parameters.

Which roofing felt is best for a roof?

Popular in construction, in demand, irreplaceable - roofing felt. For a long time, this product has been relevant - roofing felt is used for roofs as a roofing covering, for waterproofing various structures in construction, as a cushioning layer. This is a durable, moisture-resistant, inexpensive material.

There are many types of roofing felt on the market, which differ in technical characteristics and cost. It is worth considering it in detail in order to understand which types of roofing felt should be used in individual construction.

If you don’t know which roofing material is best for a roof, let’s look at the features, positive characteristics and disadvantages of the material.

Main types

Depending on where the waterproofing material is intended to be used, lining and roofing roofing felt are available on the market. These two types differ in design, installation method and technical characteristics.

The main material for the production of roofing felt is bitumen. It can be traditional and oxidized . But the base can be made from cardboard or fiberglass . Accordingly, if you lay cardboard roofing felt, then, under the influence of moisture, the bottom layer will quickly collapse.

This problem especially applies to lining roofing felt when laid horizontally. Also, the cardboard base has low bending resistance, and therefore, if it is laid incorrectly or if the installation technology is violated, cracks may occur.

Fiberglass roofing material is of better quality, but is more expensive. It is highly durable and suitable for insulating load-bearing walls near their base. Used for horizontal and vertical installation - the quality of the coating does not suffer from this. It is often used for waterproofing strip foundations; it has low deformation properties, so this is the best option for waterproofing the foundations of large and small buildings.

Grades RKP-300 and RKP-350 belong to the group of lining roofing felts and are used to insulate the lower layers of roofing. But, if you provide high-quality waterproofing of the seams, then this type can also be laid on the top layer of the roof.

The RKP-400 brand perfectly protects the building from both the roof and walls. It is initially produced of good quality, resistant to weathering and high humidity, and is often used in conjunction with glassine to increase the durability of the coating.

Pros and cons

There are no ideal materials consisting only of advantages. Each has both advantages and disadvantages.

Roofing felt is no exception; during use, the following advantages have been identified:

- the price is so affordable that any average person can afford to buy it, while it has good technological characteristics;

- excellent waterproofing properties. When arranging a roof using this material, you don’t have to worry about moisture getting under the roof;

- good sound insulation. If we compare roofing felt and metal roofing, the former absorbs noise from rain and hail;

- tear-resistant yet very flexible. Thanks to its flexibility, working with the material is very comfortable;

- easy to transport, since the weight of the rolls is small;

- A wide variety of species promotes individual choice.

And all these advantages at an affordable price. But we can’t help but mention the disadvantages:

- service life of five years. There is, of course, a more durable product - euroroofing material, which can be used for up to 30 years, but its cost is much higher. So you will have to periodically repair leaks;

- for installation, you will have to install a continuous sheathing with several rows of lining. This will require additional funds, time and effort.

When laying, bitumen mastic is used to glue the insulator, which can soften at a temperature of 50 degrees, which can result in depressurization.

These shortcomings are not so significant and with proper roofing, they can be avoided.

Technology and step-by-step instructions

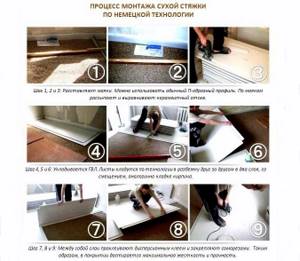

Make a standard dry screed with gypsum plasterboard in four steps:

- Preparing the base.

- Laying damper tape along the walls and plastic film along the floor.

- Backfilling of insulation with alignment along the beacons.

- Installation of gypsum fiber sheets.

GVL can be replaced with OSB or chipboard. However, it is best to take regular or special moisture-resistant gypsum boards with cellulose fiber. They are more resistant to moisture and do not contribute to the spread of fire.

Dry screed installation technology using German technology

Preparing the floor surface

To prepare the interfloor ceiling, it is enough to remove the old flooring and any debris from this base. There is no need to be particularly zealous with its alignment. If there are deep and wide cracks in the concrete, they should be repaired. But various potholes can be left under a dry screed without repair. The backfill will level everything out later.

Step-by-step instructions for dry screed with vermiculite

Laying vapor and waterproofing, damper tape

Waterproofing should be spread to the walls above the subfloor being created. And the main thing when laying polyethylene film is not to leave gaps in the waterproofing substrate. If you have to join it, then this must be done using tape. Plus, at this stage, edge tape is installed along the walls to compensate for the expansion of the screed and reduce the risk of cracking.

Laying dry screed with expanded clay

Backfill

The dry backfill is first poured onto the floor and lightly leveled so as to simply remove the bumps. Then, using beacons or guides made from drywall profiles installed under the level, the main alignment is carried out. As a result, a smooth surface without slopes should be formed. The profiles can then be removed and will no longer be needed.

How to properly make a dry screed on perlite

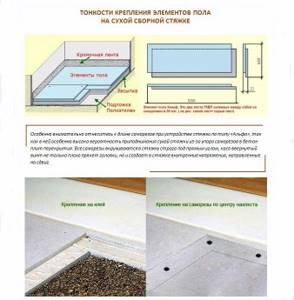

Installation of gypsum fiber elements

GVL installation is carried out in two layers laid on top of each other and fixed with self-tapping screws. In this case, the upper insert should lie at the junction of the lower ones. If the seams at the top and bottom end up in the same place, the screed will definitely fall apart.

Laying the sheets should not cause any difficulties. Replacing electrical wiring in an apartment or plumbing yourself is even more difficult. The main thing is not to step off the laid slabs and not to trample on the backfill. And finally, you will need to putty the joints and screw heads with plaster compound.

Floor fixing

Types of material

What is roofing felt is a broad concept, and it can be divided into:

Material composition:

- cardboard saturated with petroleum bitumen;

- fireproof bitumen applied on both sides of the material;

- decorative powder applied to protect from sunlight and from gluing of the material in the roll.

This is a classic roofing material, but nowadays innovative technologies are used in its production, thanks to which the use of fiberglass and polymers has become possible. To fully understand the choice of insulator for roof installation, consider modified materials.

Fiberglass or waterproofing material

Instead of cardboard, this material was based on fiberglass, which has better characteristics - it does not crack or rot. On top, to protect against moisture, the glass roofing material is covered with mineral crumbs. Excellent for highly sloping roofs. For 20 years it does not require repair. It is worth considering the characteristics of this material in more detail.

Advantages

The material is quite new, but has already become popular and in demand. They call it armored and here's why:

- due to the fact that it can withstand a wide range of temperatures, bubbles and cracks do not form on it;

- unlike cardboard, fiberglass does not rot, which helps to increase the service life of the material;

- not subject to wind loads, has increased tensile strength, which cannot be said about classic roofing felt;

- service life - 20 years with a single-layer coating, when using multi-layer installation of waterproofing, the period increases to 50 years;

- ease of installation under any conditions; unlike roofing felt, waterproofing does not crack even at sub-zero temperatures, so the material can be laid even in winter.

It has soundproofing properties, muffling sounds from rain and hail.

This is a flammable roofing material, but its characteristics allow it to withstand elevated temperatures, for example, at 80 degrees, the material will not melt or start flowing.

If we compare which is better than roofing felt or waterproofing, it should be noted that a roof made from the second will be more expensive, but will last much longer without the need for repairs.

According to the characteristics, it is the same ordinary roofing material, with a cardboard base, coated with a layer of binder. Thanks to this composition, a good, tight adhesion to the roof is obtained. Installation is carried out using a burner, which melts the material, and there is no need to use mastic. The coating will last 15 years

Ruberoid with a self-adhesive layer

Its distinctive feature is its coating with a self-adhesive layer protected by film. During installation, the film is removed and simply glued to the wooden surface of the roof. Under the influence of sunlight, the material softens and adheres tightly to the surface. The use of fire and various types of solvents is not required.

Euroroofing material

It appeared on the market not so long ago; its production uses materials unusual for a regular product. Textile base impregnated with bitumen and synthetic rubber, which significantly improves the technological characteristics of the material. The next layer is polymer films, which are covered with a protective coating that performs a decorative function, as it has different colors. Euroroofing material can serve without leaks or damage for up to 30 years.

Polyurea "Ecotermix"

Polyurea is a liquid composition applied by spraying using a special installation.

This is a unique composition obtained on the basis of natural ingredients. It is a new generation polymer that combines high strength and elasticity, as well as resistance to any external factors! Polyurea is a liquid composition applied by spraying using a special installation that mixes two components (base and catalyst) and feeds the finished mixture into a spray bottle. Waterproofing with polyurea has many advantages:

- It is a seamless waterproofing - the entire surface of the base is covered with an even layer without a single seam. This ensures complete tightness and the highest degree of protection reliability

- Minimum weight - the material is applied to the base in two layers, the total thickness of which does not exceed three millimeters! And at the same time, polyurea can withstand enormous loads (Shore hardness is more than 90 units). The base experiences virtually no additional loads

- Resistance to any influences - chemical, mechanical, thermal influences are absolutely not dangerous for Ecotermix polyurea

- Long service life without maintenance - it can exceed 50 years, while the effectiveness of waterproofing will not decrease at all

- Efficiency of application - the spraying method allows you to apply polyurea quickly, and the base does not require special preparation, except that it must be clean. It is important that complete hardening of Ecotermix polyurea occurs in less than 60 minutes, and primary hardening in less than a minute! That is, the work is handed over on the day of its completion.

- It can be applied to any materials - this allows waterproofing of concrete, steel, and wooden structures. At the same time, polyurea resists combustion, therefore increases the level of fire safety of wooden houses

- Optimal price-quality ratio - offers optimal and fully justified prices for polyurea waterproofing of any objects, regardless of their scale

Specialists use polyurea of excellent quality to waterproof any industrial and residential buildings, outbuildings, machinery and equipment.

Request a call right now

Causes of leaks on a roof covered with roofing felt

The material is waterproof, resistant to the formation of fungus and mold, and is not subject to decay in the sun, all this indicates the reliability of such a coating. The roofing is done using open fire - the directional method.

A roof with such a coating can leak for many reasons:

- Inappropriate use. All manufacturers say that this material cannot be used as a covering material on exploited roofs, since constant mechanical impact can damage the roofing material. These recommendations are sometimes ignored, which leads to damage that will have to be repaired.

- Exposure to precipitation. When it rains, a small amount of water penetrates the top layer of the material, and when cold weather sets in, it freezes, which can lead to the appearance of microcracks.

- Wind load. In some regions, winds often blow with strong gusts, the material may not withstand it and damage appears on it.

- Illiterate installation. Roof leakage can occur due to non-compliance with the material laying technology. For example, incorrectly executed overlaps, unprepared roofing.

- Poor quality material. This is a very common cause of material damage and leaks. When buying cheap material, you should be prepared for the fact that you will often have to repair your roofing felt roof.

Repair work

Any roofing material breaks down over time and begins to require repair - roofing felt is no exception, since roofing felt for roofing, installed at 6, only lasts 15 years. First, microcracks appear, which are washed with water, which leads to leaks.

You can fix such defects yourself:

- Patch repair. This type of repair is carried out if the damage to the coating is minor and rare. Small patches are applied to the roofing felt. This method has one difficult nuance - on the top layer of the coating there is stone chips, which reduces adhesion when gluing the patch. This repair can repair the roof for 2 seasons.

- Repairing the roof with roofing felt on the old covering. If there are a large number of cracks, you can fuse or glue several new layers of roofing material. Before installation, the old coating is cleaned, removing crumbs, and treated with bitumen or mastic. This repair option is possible if there are no blisters or moisture between the layers on the roofing material.

- Repair with dismantling of old roofing felt. If a roof is leaking and has not been repaired for more than 15 years, the old covering will have to be removed down to the base. Then a new multi-layer roofing felt coating is installed.

When carrying out repair work, do not forget that roofing felt is a flammable material, and installation must be carried out in compliance with safety precautions.

Installation methods

Installation of roofing felt necessarily includes preparation of the base - this is grouting the concrete slab with cement or laying a wooden base made of boards on the rafters. Also, the material itself is rolled out and leveled so that it straightens a little. It is kept in this position for 24 hours, after which the topping is removed from the bottom layer with kerosene.

To glue the material, you will have to stock up on bitumen mastic, which can be used hot or cold. Hot is prepared in a filler-bitumen ratio of 1:8. The filler can be chalk, sawdust, asbestos, peat chips, which are sifted and poured into bitumen. Next, the mixture is heated over a fire and stirred until smooth. If cold mastic is used, the bitumen is melted and dehydrated with diesel fuel or kerosene.

Laying roofing felt begins from the bottom of the roof, valley, and gutters. The material is glued with an overlap of about 20 cm of individual strips on top of each other. During gluing, it is important to ensure that no swelling occurs. The built-up roofing felt is laid using a torch or hair dryer.