The most popular building materials for insulating buildings are polystyrene foam and penoplex. They have many identical characteristics: light weight, ease of processing. But, nevertheless, they have certain differences. Therefore, it is necessary to figure out what is better for insulation: polystyrene foam or penoplex?

Foam plastic or penoplex - which is better?

Until recently, rooms were insulated with polystyrene foam. But over time, a new, more modern penoplex appeared, which has different properties than its predecessor, although the same raw materials are used for their manufacture. This article is aimed at determining the capabilities of these materials, their fundamental differences from each other, and helping to make the right choice.

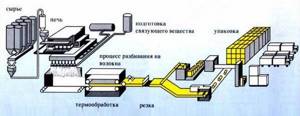

Production of foam plastic and penoplex

Polystyrene is used to make these insulation materials, but their production itself is different. Thus, during the production of polystyrene foam, polystyrene granules are treated with steam, and therefore their volume increases 50 times. When gluing together, the output is a rather airy raw material, in which there are micropores and voids between the granules. To achieve high density, the granules must be well compressed to improve the quality of the material. Polystyrene foam is often called expanded polystyrene.

Foam production

To create penoplex, the extrusion method is used. Due to the significant temperature conditions and high pressure, a material with a uniform dense structure and excellent consistency is obtained. This product is also commonly called extruded polystyrene foam.

Penoplex production

Characteristics of various materials

Table 1

The value of the standardized heat transfer resistance of an external wall depends on the region of the Russian Federation in which the building is located.

table 2

The required layer of thermal insulation material is determined based on the following conditions:

- the external enclosing structure of the building is solid ceramic brick of plastic pressing with a thickness of 380 mm;

- interior finishing – plaster with cement-lime composition 20 mm thick;

- external finishing – a layer of polymer-cement plaster, layer thickness 0.8 cm;

- the coefficient of thermal homogeneity of the structure is 0.9;

- thermal conductivity coefficient of insulation - λA=0.040; λB=0.042.

Characteristics of penoplex and polystyrene foam

Penoplex is denser than polystyrene foam, which is why it weighs more and, therefore, can withstand a greater load. The tightness of the granules in the production of polystyrene foam is not strong, so in terms of its thermal insulation properties it is inferior to penoplex, which is highly compressed.

Penoplex slabs

In order for the protection against cold to be the same, you need to buy 25% less penoplex than polystyrene foam.

Penoplex belongs to the category of moisture-resistant materials. It has a water absorption rate of 0.35%, while for foam plastic this figure reaches 2.0%. Foam plastic has a greater degree of vapor permeability than penoplex, for which this value is almost zero. But it is worth noting that these two insulation materials have a very low degree of vapor permeability.

Foam boards

As for fragility, foam loses here. It is more fragile, easily crumbles and breaks, and is afraid of bends. The strength of penoplex is 6 times greater, and it cannot be broken without much effort. It also bends well, which compares favorably with polystyrene foam.

In terms of operating time, both of these materials will last quite a long time, but penoplex will retain its qualities longer. Over time, the foam will begin to crumble.

Polystyrene foam is more fragile than polystyrene foam

You need to know that both of these insulation materials are afraid of bright sun and negative atmospheric influences.

Polystyrene foam and polystyrene foam can be cut with an ordinary knife, but when working with the first material, great care must be taken, as it may break. Especially when it comes to three-centimeter sheets.

If we take into account the pricing policy, the cost of polystyrene foam is much less, so in the construction of high-rise buildings this insulation is used so that the cost of the project does not increase. It is also chosen by those who have limited financial capabilities.

Comparison of materials by operating temperature

Quite often in construction today penoplex or polystyrene foam is used. You can decide which is better after reading the information presented in the article. For example, it is also necessary to take into account the temperature at which normal operation is possible. In this regard, the difference is almost unnoticeable, because both materials feel great at low temperatures, but if the thermometer does not fall below -50 ° C. After reaching this mark, the material begins to lose its properties, while the upper maximum reaches +70 ° C, which is true for polystyrene foam, and 75 ° C for penoplex. These insulation materials should not be left exposed to direct sunlight. If you put a piece of foam plastic in the sun, the result will not take long to appear.

Properties of foam plastic

Polystyrene foam belongs to the category of artificial materials; it is not afraid of corrosion, excessive humidity, and is not afraid of the harmful effects of external factors. In its basic properties it is similar to mineral wool and is practically in no way inferior to it. Its density is slightly less, and its thermal conductivity is slightly lower.

Walls insulated with foam plastic “stop breathing” because air does not pass through it.

It has great thermal conductivity. It can be used at temperatures from -40 degrees to +70 degrees. According to the flammability class, it is classified as a fire hazardous material. Such insulation can be safely used for about 30 years.

Properties of penoplex

It is widely used for floor insulation, and there is no need for a full-fledged frame. Its thermal conductivity indicators are significant, which makes it possible to use it in small quantities.

If floor insulation with polystyrene foam requires a thickness of 8-11 cm, then with penoplex this figure decreases to 3-4 cm. Moreover, the floor will be warmer than with polystyrene foam. This makes it possible to widely use penoplex in the Far North with its critical sub-zero temperatures.

Floor insulation with penoplex

Penoplex has absorbed the best properties of polystyrene foam, only improving them significantly. This means good strength and low breakability. As for flammability, it is lower compared to polystyrene foam. In terms of cost, it is superior to polystyrene foam, but the price-quality ratio is excellent.

Balcony insulation with penoplex

This material tolerates operating temperatures from -50 degrees to +75 degrees and will last for half a century without losing its capabilities.

Comparison of thermal insulation qualities

If you are thinking about the question of which is better - polystyrene foam or polystyrene foam, then first of all you need to pay attention to the quality of thermal conductivity. These parameters differ for the materials described. The thermal conductivity of foam plastic varies within the range of 0.035-0.05 W/m*C, while for penoplex this parameter is 0.028 W/m*C. This allows us to conclude that penoplex retains heat somewhat better. If you take a slab of 25 mm polystyrene foam, it will be identical in thermal insulation properties to a 20 mm slab of polystyrene foam. The first option is only slightly inferior to the second, and in large areas this can result in good space savings.

Pros and cons of penoplex

Like any other insulation, penoplex has its own positive and negative properties.

| Advantages | Flaws |

| Low vapor permeability, preventing the absorption of moisture, water and condensation | Excessive fire hazard |

| Low thermal conductivity | May be damaged by rodents |

| Excellent durability | Capable of melting and flaming |

| Ability to withstand significant loads | Requires special handling to minimize the possibility of fire |

| Significant service life of the material | |

| Simplicity and speed during installation work | |

| Light weight | |

| Good combination of "Price - Quality" |

Pros and cons of foam plastic

When choosing insulation, you must first become familiar with its strengths and weaknesses. So, the main positive and negative aspects of polystyrene foam are the following:

| Advantages | Flaws |

| Affordable price | During the combustion process, toxic substances are released that have a negative impact on the human body. |

| Excellent thermal insulation properties | Possibility of releasing harmful substances even with a slight increase in temperature |

| Light weight | Able to create a vapor barrier |

| Wide range of applications and versatility | Hygroscopic |

| Long service life | Does not tolerate direct sunlight |

| Resistant to fungal growths and various microorganisms | Can be destroyed by rodents |

| Easy to install | Instability to various types of solvents has been revealed |

| Environmentally friendly product | Does not tolerate mechanical damage well |

| Noise insulation is minimal |

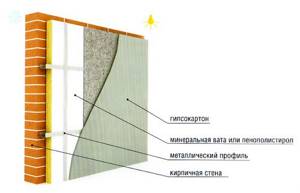

Selection of material by area of use

Quite often, modern developers wonder what is better - penoplex or polystyrene foam for insulation. To solve this problem, it is necessary to decide on which part of the building the material will be installed. For example, for a façade it is best to choose polystyrene foam, since it is cheaper and can allow air to pass through. This choice will reduce the cost of vapor barrier, because the wall will not lose its ability to breathe. For internal insulation of a house, it is best not to use such materials, although they themselves are environmentally friendly, they can be impregnated with special solutions. The latter emit toxic substances during operation.

If you are thinking about what is the best way to insulate a house - polystyrene foam/penoplex - then the latter option is better to choose for loggias or balconies. It has lower thermal conductivity and does not reduce the internal space as much. But if you have a flat roof and need to insulate it, both options are suitable. The ceiling can also be thermally insulated with any material of your choice. However, this decision is justified if you do not plan to walk through the attic afterwards. Otherwise, it is best to choose penoplex. Both materials are suitable for floor insulation, but it is better to make the rough surface using joists.

Foam plastic or penoplex: which is better for external insulation

If we take into account the fact that penoplex is superior in density to polystyrene foam, nevertheless, residential buildings are insulated from the outside with the latter. Foam boards are classified as breathable, so walls insulated with them are able to “breathe”. Otherwise, condensation may appear between the building structure and the insulation, which will adversely affect the strength of the object, even to the point of its destruction.

Insulating the outside of the house with polystyrene foam

Penoplex is also used to insulate the external walls of buildings, but a vapor-permeable membrane must be laid between it and the building, which will automatically lead to an increase in the cost of the facility and an extension of construction time. As for non-residential buildings, insulation is carried out with both one and another material.

Insulation of external walls with penoplex

Expanded polystyrene is used, among other things, for insulating ceilings. But it is preferable to use penoplex compared to its competitor. There is one advantage that needs to be taken into account: foam plastic does not need to be covered after it is installed, as it is strong enough to support human weight. With polystyrene foam it is more difficult in this regard. It requires a hard covering, such as covering with boards.

Roof insulation with penoplex

Expanded polystyrene foam can be used to fill frame structures. This makes it possible to build such structures at high speed, but the soundproofing properties there will be minimal. But there are buildings that do not need sound insulation at all.

Insulation of various structures

In principle, both insulation materials have a wide range of applications, but when insulating external walls, it is sometimes advisable to purchase inexpensive and breathable foam plastic, and when arranging a loggia, penoplex.

The latter material is durable, which allows it to be used for thermal insulation of floors, insulation of pipes (due to its good ductility), and even insulation of the base or foundation of a house. But, as mentioned above, penoplex is much more expensive , and in some cases the additional costs are simply impractical.

Exterior walls of the house

Foam, which is applied to external surfaces, must not only be protected from exposure to ultraviolet radiation, but also take into account that this material does not allow steam to pass through. Otherwise, the isolated part of the wall will become a breeding ground for various bacteria.

Therefore, wooden houses should not be treated with polystyrene foam.

It should also be taken into account that this material is highly flammable , it can spread combustion and independently increase the fire, while releasing toxins hazardous to human health. That is, if simple polystyrene foam is used outside during the construction of a building, it must, at a minimum, be insulated with special care.

When using penoplex to insulate external walls, it can be used not only as insulation, but also as a building material for some auxiliary structural elements.

In addition, penoplex is not so afraid of moisture; it is more biologically stable than its competitor; rodents do not like to live in it. True, it also does not have high fire safety, although, unlike foam plastic, it simply burns without supporting or spreading the fire further.

Read detailed instructions on insulating external walls with foam plastic here.

In general, polystyrene is actively replacing polystyrene foam for external insulation of walls more and more often. In Europe, foam plastic is not used at all for the exterior decoration of buildings; in other countries, including ours, it is also increasingly being replaced with polystyrene foam.

Interior walls of the house

Regarding the issues of active energy saving, experts in this field increasingly recommend thoroughly insulating walls using modern insulation materials to reduce heat loss. These are both foam plastic and penoplex, and both are equally suitable for this purpose, having excellent thermal insulation properties.

Polystyrene foam is inexpensive and very easy to install; you can carry out insulation work on your home yourself, without involving specialists. It is used for insulation of warehouses where non-combustible materials are stored, technical buildings, and other buildings.

Penoplex is more resistant to mechanical damage, its slabs do not crumble, but their insulation will cost, as already mentioned, more.

Sometimes it is necessary to create additional sound insulation in a room, for this they take three-centimeter polystyrene foam , but much thicker polystyrene will have to be used. By the way, this will reduce the total space of the room, which is important, especially in a small apartment, which is not very large anyway.

Read our article about what material to use to decorate the walls in your apartment.

To insulate a balcony, you can use any of two materials. The loggia should be insulated with a simple five-centimeter polystyrene foam; there is no need to buy expensive materials for this work.

If the winters are very cold, you can take thicker foam, up to ten centimeters. But if the balcony is small, you can purchase penoplex for this purpose.

Floor

The floor is insulated only with polystyrene foam, since polystyrene foam is too fragile and has low density, so screed cannot be placed on it. Penoplex, on the contrary, will withstand high loads, and the floor will not only be warm, but also durable.

This material is used to create a system called “warm floor”, where thermal insulation plays a key role, as it reduces heat transfer in two directions at once (top and bottom). Floor insulation with penoplex is effective even with high humidity and constant mechanical loads.

Attics and roofs

When insulating the roof inside both materials are suitable , but if you need to make the floor in the attic warmer, you should still choose penoplex. By the way, in the attic you can not put other materials on top, you can walk directly on the foam.

To insulate the roof, foam boards are also used, which are carefully covered with a waterproofing layer . If the roof is cold, its inner part is insulated with polystyrene foam, and the outer part with polystyrene foam, while leaving sufficient space for ventilation.

Thus, for thermal insulation you can use both of the materials described above, depending on what needs to be insulated. Penoplex is suitable for exterior decoration, for floors and roofs, but it is much more expensive, and sometimes foam plastic is enough.

You can watch the process of insulating external walls in the video:

Foam plastic or penoplex: which is better for internal insulation

It is preferable to carry out such work using penoplex. If its properties are inferior to foam plastic for external work, then for internal insulation it is several times superior to it. Its positive properties, such as moisture resistance and airtightness, make it possible not to create an additional vapor barrier between the insulating materials and the wall of the building itself.

But insulating premises from the inside is a necessary measure, and from the outside the object remains unprotected from temperature changes and negative atmospheric phenomena. It is also worth remembering the possible release of harmful substances from such building materials into the room.

Floors are insulated with penoplex and foam plastic. In this process, they are almost equal in their characteristics, given their fire resistance and environmental friendliness. These materials are currently widely used when laying heated floors.

Floor insulation with foam plastic

It is worth noting that after installing polystyrene foam boards, they are hidden under various other coatings, so most of their negative qualities are negated.

Where is each of these materials used?

Polystyrene foam is often the preferred material due to its very affordable cost.

However, it is penoplex that is the highest quality and most reliable, but also quite expensive, insulation.

When choosing between materials such as expanded polystyrene and penoplex in conditions of external insulation of the facade of a residential building, it is always the penoplex that loses.

The use of lower quality ponoplast is quite justified in some cases. This material is most often used in the insulation of ventilated facades, which is due to significant moisture absorption and increased air permeability. Insufficient adhesion indicators do not allow external insulation above the base using penoplex.

It is important to remember that both insulating materials help to perform plastering when using reinforcing mesh. In this case, there is a great opportunity to save significant money on high-quality and durable exterior finishing.

Areas of application of foam plastic

In addition to the already given examples of insulation of walls, floors and roofs, polystyrene foam is also used in the following cases:

- For insulating the foundation. It is recommended to insulate it to the depth of soil freezing - that is, on average 1 meter. But it is best to completely insulate the surface of the foundation, and then backfill the pit. It is very important that a continuous thermal insulation contour is maintained between the walls of the foundation or basement and the walls of the first floor of the building. This leads to the absence of cold bridges. If it is planned to build a three-layer wall, which consists of a base, insulation and a decorative wall, then the same structural elements must be in the basement so that the thermal insulation layers can be connected. The same principle of insulation is used in relation to the two-layer wall of the foundation and basement. The only drawback is that the rigidity of the slab does not allow it to adhere tightly to an uneven surface. Therefore, dowels with wide heads are used.

- For insulating the attic. To insulate the slopes of a residential attic, foam plastic is placed as follows: on top of the rafters, while they remain open, decorating the room, or between the rafters, then the foam plastic is carefully cut and additionally fastened, which significantly increases the duration of construction and the cost of specialized teams. Polystyrene foam can also be attached to the supporting frame or under the rafters, but this will significantly reduce the overall volume of the room.

- To insulate flat roofs, polystyrene foam with special rigidity is used. The base is mainly concrete, rarely corrugated board or wood. Moisture insulation in the form of roofing material or film is spread on top, and then foam plastic is tightly laid.

Insulating the walls of a frame house with polystyrene foam (spring 2021)

So, the 2021 construction season is over for me and now it’s time to once again think about and analyze what has been done, identify possible miscalculations (to eliminate them in the future) and share my experience.

In the process of preparing for the construction of a frame house, I decided to use PSB-S-25 foam plastic as insulation (total insulation layer - 200 mm, of which 150 mm - in the walls, 50 mm - as cross-external insulation to eliminate cold bridges along the frame posts and the gaps between them).

You can read more about the process of preparing polystyrene foam in the material “Preparing polystyrene foam for insulating a frame (04/13/2017)”

Cross frame insulation

Insulation of a frame house with polystyrene foam - Insulation of a frame house with foam plastic

I did cross-insulation of a frame house, which is one of the best options for additional thermal insulation of a wooden frame (as it allows you to block all cold bridges in a wooden frame) in the fall of 2021 (more about cross-insulation of my frame house).

In addition, external cross-insulation of all walls made it possible to form unique walls that served as a barrier to snow all winter: a frame with external cross-insulation installed under the roof stood quietly all winter.

The photo shows a view of a house mothballed for the winter (the photo was taken after re-preservation, I began making external sheathing for the siding).

In general, the house survived the winter normally, the only thing that can be noted is that a strong wind blew out a couple of sheets of foam plastic where they were loosely pressed by the bars. I hastily, on one of my inspection visits, attached them with three slats to self-tapping screws (you can see them in the photo).

The inside of the frame was not insulated in any way until the spring of 2021, this allowed all the boards of the frame to dry well before I started insulating the walls internally.

Internal insulation of walls of a frame house with foam plastic

Let me draw your attention once again:

- I built the frame from boards of natural moisture, which had been drying in my stack for 3 months before the construction of the frame began;

- before the internal walls were insulated, the frame stood under the roof for another six months after construction, being well ventilated through the holes under the roof;

- The total drying time for the frame boards was about a year.

The distance between the frame posts was generally 50 cm, with the calculation for a 200 x 100 cm sheet of foam cut lengthwise.

Insulation of the frame with foam plastic - Insulation of the frame with foam plastic

When cutting (if necessary, if there was a deviation from the standard 50 cm), I measured the width of the opening to be filled, and set the height of the wire to the required width of the foam (which was stretched between the two posts with a spring and therefore did not move down).

I regulated the cutting speed using the current passed through the wire.

All sheets of foam plastic were laid with an overlap, where it was necessary to cover the joining gaps, and were also foamed. To be fair, it must be said that very little foam was used (3 or 4 balloons on the first floor), since I did not leave any gaps for installation and almost all the sheets were inserted by surprise (often with quite a lot of effort). The photo shows intermediate results.

Do mice eat styrofoam?

Anyone who is going to use polystyrene foam to insulate a frame house has a question: “do mice eat polystyrene foam”? I'll share my little (so far) experience.

So:

- the foam lay in the open air for 5 months - not a single mouse, not a single mink, not a single mouse poop;

- external cross-insulation, 2 stacks of polystyrene foam inside the house - 6 months (autumn, winter, spring 2017-2018) - not a single mouse, not a single mink, not a single mouse poop;

- internal insulation of the first floor - 4 months (spring, summer, autumn 2018) - not a single mouse, not a single mink, not a single mouse poop.

Thus, within a year and a half, the mice showed absolute indifference to polystyrene foam. I think that foam plastic, as such, is absolutely not interested in them. Warmth and food are much more interesting for them, but this is not yet in my house. Therefore, mice too.

Anticipating their possible interest in the future, I provided for the arrangement of a metal mesh with a fine mesh along the entire perimeter of the base. In addition, three neighbor cats like to hang out in my yard... Let's hope that there will be no mice in the future.

Areas of application of penoplex

This thermal insulation material is used in various fields of construction:

- To protect the foundation. This material has a number of positive qualities. If you use such insulation, the depth of soil freezing decreases, therefore there is no need to lay a deep foundation. This makes it possible to reduce the work of digging a pit and arranging a deep concrete foundation, which could lead to additional financial and labor costs. At the same time, moisture will not penetrate into the foundation, which will have a positive effect on the human body due to the provision of a favorable microclimate. Moreover, the presence of penoplex helps to save on heating costs.

- For insulation of basements. Due to the fact that penoplex is a moisture-resistant material, it can be laid on top of gravel, which is used as a rough floor covering. If there is a foam concrete base, it is first covered with waterproofing, and then penoplex is laid. If the floor on the ground floor is supposed to be warm, then the waterproofing layer is increased.

- In order to insulate balconies and roofs. Penoplex is light enough, so it will not unnecessarily load the floor slabs on the balcony. You can install this material yourself, thereby reducing the cost of paying for thermal insulation work. As for the roof, it helps reduce heat loss and the service life of the roof is significantly increased. In this case, penoplex is laid on the outside of the roof in such a way that there remains a cavity for ventilation, which can minimize the evaporation process. Before thermal insulation work is carried out, the roof is cleaned, waterproofing work is carried out, then foam boards are installed.

Comparison by composition

The materials described in the article are actively used in construction, mostly in the field of thermal insulation; they can also be used to insulate sound. They are manufactured using similar technologies, which involve foaming polystyrene. Polystyrene foam is an insulating material that contains 98% air and 2% polystyrene. This affects the low cost, because the stove requires only 2% of raw materials. Penoplex acts as a synthetic material for thermal insulation; it is made from extruded polystyrene foam; it is created using the technology of foaming raw materials.