Home / Boiler automation

Back

Published: 06/13/2019

Reading time: 6 min

1

11250

The safety valve for the boiler prevents emergency hazards. This happens when the water overheats and pressure increases, resulting in a rupture of the main line or the casing of the heat generator. Therefore, you should know how to correctly select, install and configure this important element of the boiler.

- 1 Design and principle of operation of the valve

- 2 Types of safety valves

- 3 How to choose a reliable valve

- 4 Installation location of safety valves

- 5 Setting safety valves

- 6 The act of setting

Types of safety valves

These protection elements are classified in different ways.

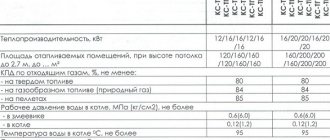

| Principle of operation | Shutter lift height | Shutter opening method | Spool loading method | |

| 1 | Direct action | Low lift | Proportional | Spring |

| 2 | Indirect action | Full lift | Two-stage | Lever-gas |

| 3 | Pulse |

Spring ones are the most common, used for small boiler rooms. They have a simple and reliable design and the ability to easily adjust the operating pressure in the system. Another advantage is the low cost. Lever safety devices are not particularly popular, because, basically, the model range is represented by diameters from 50 mm. They are used in the industrial field. Pulse devices are used on steam boilers with pressures greater than 39 kgf/sq.cm (3.9 MPa). At least 2 pieces are installed on each boiler. (control and worker). Low-lift ones have a valve lift height of 5% of the seat diameter, therefore they have a low throughput. The advantages include: simple design, affordable price.

Low lift and full lift

In full-lift valves, the bolt rises to a height of at least 25% of the seat diameter. They are classified as two-stage. They are characterized by high throughput, high cost and complex design.

The advantages of using a proportional valve include:

- Installing a solid fuel boiler - analysis of installation nuances

- opening the shutter according to need;

- lightweight design;

- low cost;

- vibrations occur automatically.

Two-stage safety devices open the bolt instantly. They are prohibited from being installed in the DHW circuit, as this leads to a drop in pressure in the system, and after that the device instantly closes, causing water hammer.

The disadvantage of two-stage devices is self-oscillation of the shutter. The reason for this is exceeding the standard size or variable emergency flow of the medium.

Principle of operation

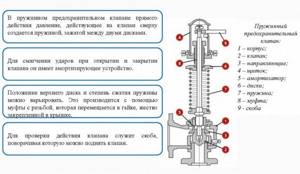

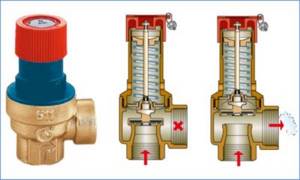

The valve that protects the boiler has a simple device and operates on a principle that is understandable even to a schoolchild. The device consists of a straight fitting with a 90-degree outlet and a spring-loaded seal that closes the side passage. When the pressure in the system increases due to overheating, exceeding the pressing force of the spring holding the valve in a stationary position, it rises up and opens the side hole.

Excess liquid begins to pour out from the side and is sent to a container, drainage or sewer system. After bleeding part of the coolant, the pressure in the system and on the valve weakens, the spring puts it in place, closing the side pipe.

Spring-type structural device

How to choose a reliable valve

In the design of the heating system, it is necessary to clearly define the maximum permissible pressure values. The productive capacity of the boiler or pump, volume, and circulation features of the temperature of the working environment are also taken into account. Based on this, the type and design features are selected. Of the previously listed types, users are recommended to use spring-loaded safety valves . They are perfect for boilers with low power. Low or medium lift devices are also used for hot water systems.

If the working fluid is discharged into the environment, an open type device should be selected. If the discharge occurs into the drain, then a housing design with a threaded outlet outlet is used.

It is prohibited to install a protective device with an excessive response threshold. It won't work when it needs to.

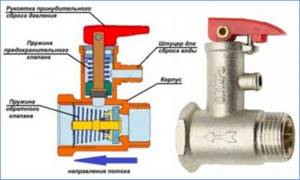

Design and principle of operation of the valve

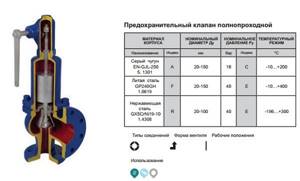

Safety valve design:

- protective cover;

- outlet;

- fillings;

- compression springs;

- cone;

- saddles;

- pressure chamber.

The body is made using hot stamping technology, usually brass is used, and therefore has a long service life. The control unit is made of heat-resistant plastic and does not change its shape. There are different types of safety valves, but the principle of operation is the same. The saddle is acted upon by a spring mechanism and is in the closed state. If the pressure in the pipeline is stronger than the force of the compression spring, the seat will open and the coolant will be released.

Installation location of safety valves

When choosing a location for installing safety devices, a number of rules must be observed:

- Pulse valves must be installed indoors, taking into account the climate they are intended for (temperate or tropical).

- For maintenance, repair, assembly and disassembly of products, it is recommended to organize the place so that these actions are carried out without cutting out from the water supply system.

- Carry out the installation in accordance with the design working drawings.

- The main valve is mounted by welding to the fitting only vertically upwards. Deviation is possible, but not more than 0.2 mm per 100 mm of the height of the protective device.

- When welding, exclude the possibility of splashes, burrs, and scale getting into its cavity.

- After cooking, the seams need heat treatment, based on the requirements of the current instructions for installing water supply system equipment.

- It is prohibited to install shut-off devices and filters on the pipes that connect to the valve and pressure relief pipelines.

- The valve lever is installed horizontally.

- In order to control the pressure, you need to place a pressure gauge in front of the fitting.

- The valve for the heating system can be installed in several places in the pipeline.

Setting up safety valves

The protective devices are configured after installation and flushing of the system.

Checking safety valves takes place in several stages:

- A pressure setting that is set slightly above the maximum operating pressure.

- Check the pressure when opening, it should not exceed the minimum. Corresponds to normal operation. The pressure in the spring safety valve can be adjusted by rotating the adjusting screw, which compresses the spring. The lever is adjusted by changing the weight of the load.

- Checking for complete opening and closing.

The frequency of checking safety valves is once a quarter.

After all the adjustment manipulations, it is necessary to seal, assign a number and apply it to the body of the protective device (or on a plate, it is welded to the valve body; it indicates: installation location, pressure), draw up an operational card or technological passport.

The act of setting

The act of setting up the safety valve is a mandatory document. It is written on each valve. The form of the act can be adjusted.

If the conditions for adjusting the device change, then entries must be made in the document. All points in the form must be filled out. If there is no separate data, they write: “ No data required .” The act also indicates the commission that accepts the readiness of the device for operation. At the end of the document, the signatures of the members of this commission are required.

Source

Water supply heating installation services

LLC DESIGN PRESTIGE

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma.html < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

Heating from DESIGN PRESTIGE LLC Type: water here > /otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

If you do not limit the heating of water in the boiler, it will boil and turn into steam, which will lead to a critical increase in pressure in the heating network. This is followed by a rupture of the pipeline or water jacket of the heat generator. To avoid the described emergency situation, a safety valve for heating is installed at the boiler outlet, releasing excess pressure from the system. Our publication is devoted to the selection and installation of this important element.

Why might a valve leak?

The pressure relief valve in the heating system can leak for various reasons. In some situations, this is an acceptable natural process; in other cases, a leak indicates a malfunction of the device.

Leakage of the protection valve can be caused by the following reasons:

- Damage to the sealed rubber cup or disc as a result of repeated use. If during repairs a replacement part cannot be found on sale or is not included in the package, you will have to replace the device completely.

- In spring types, the opening of the side drain pipe occurs gradually; at borderline pressure values or short-term surges, the valve may partially operate and drip, which does not indicate its malfunction.

- Leakage can be caused by incorrect settings or malfunctions of the expansion tank - damage to its membrane, air escaping through a depressurized housing or a damaged nipple. In this case, sharp pressure surges are possible as a result of water hammer, causing periodic short-term leakage of coolant through the safety valve.

- The cause of leakage in some adjustable valves is fluid seeping down the stem through the top during actuation.

- If a back pressure is created at the outlet pipe above the device's response threshold, a leak will also occur.

The safety valve of steam boilers is designed to protect them from excess pressure in the system caused by various factors, and is a mandatory element when operating this type of equipment. There is a wide range of safety devices on sale from Chinese, domestic and European manufacturers, which are characterized by a relatively low cost. When purchasing, it is rational to choose a protective group from several devices, which additionally includes a pressure gauge and an air release valve.

Operating principle

Most ordinary users faced with closed water heating systems are familiar with only one type of safety valve - a simple spring valve with a fixed setting, shown in the photo. The reason is clear - these elements are installed everywhere on any boilers, since they are part of the safety group along with a pressure gauge and an air vent.

Note. Wall-mounted heat generators operating on electricity and natural gas are equipped with safety elements from the factory. They are placed inside the case and are not visible from the outside.

Let's understand how a regular emergency valve works, shown in the diagram above:

- Under normal conditions, the diaphragm, attached to the stem and supported by a spring, sits tightly in the seat and seals the passage.

- If the coolant overheats, it expands and creates excess pressure in a closed system, partially compensated by the expansion tank.

- When the amount of water pressure reaches the valve response threshold (usually 3 Bar), the spring is compressed under its influence and the membrane opens the passage. The boiling coolant is automatically discharged until the spring has enough strength to close the flow area again.

- In the event of an emergency, the owner of the house can relieve excess pressure himself by turning the handle at the top of the product.

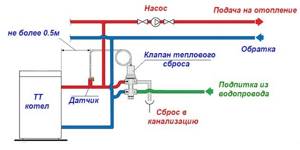

A few words about where the relief valve is installed along with the safety group in a closed heating system. Its place is on the supply line in the immediate vicinity of the boiler (recommended no further than 0.5 m).

The safety unit is always installed on the heater flow line

Important point. It is prohibited to install taps, valves and other shut-off devices on the pipeline leading from the heat generator to the safety elements.

You should not tightly connect the pipe of the product to the sewer - wet spots or puddles will indicate the valve has been activated and problems in the heating network. For example, the expansion tank failed or the circulation pump malfunctioned when working with a solid fuel boiler (the electricity may have been turned off). Often the device begins to leak due to debris getting between the seat and the plate. More about his work is described in the video:

Additional information. Masters and installers call spring relief valves blasting valves because the pressure of the coolant compresses the spring and causes the membrane to explode. Do not confuse them with explosive elements installed on the chimneys of industrial boiler houses that burn natural gas.

Types of safety valves

The traditional disruptive design described above is imperfect. The spring mechanism, driven by excessive pressure, is not accurate and may work late when the temperature in the boiler tank has reached 100 ° C or higher, that is, boiling has begun. Of course, you can try to adjust the product with a screw or change the settings (there are versions with an adjustment cap), but this does not always give the desired effect.

Point two: the safety valve for the boiler protects it from destruction, but not from overheating. After all, discharging the coolant does not allow cooling the heating unit if combustion in the furnace continues. And lastly: in open-type heating systems, such devices are generally useless, since the water in them can boil without increasing the pressure.

Leading manufacturers of heating fittings offer modern products that are free of the listed disadvantages - thermal relief valves. These protective elements react not to an increase in water pressure in the system, but to an increase in its temperature to a critical level. There are 3 types of such devices:

- waste with remote temperature sensor;

- combined device with temperature sensor and make-up circuit;

- the same with direct installation in the pipeline.

For reference. Here are the names of reliable brands whose emergency fittings can be safely purchased and used in private homes. These are manufacturers ICMA and CALEFFI (Italy), Herz Armaturen (Austria) and the world famous European brand Danfoss.

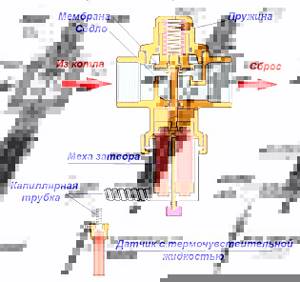

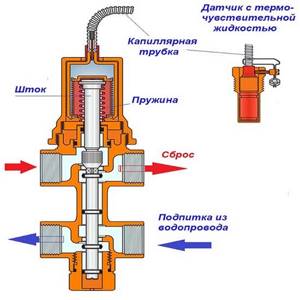

The principle of operation for all varieties is the same: a spring mechanism with a membrane (or two) is driven by a bellows with a heat-sensitive liquid that expands significantly when heated. In this way, the thermal relief valves react quite accurately when the critical temperature is reached. We invite you to consider each of them in more detail.

Element with remote sensor

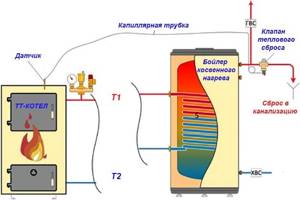

The product is the same spring mechanism, built into a housing with two pipes for connection to the supply line and discharge into the sewer. The rod that opens the plate and the path for the coolant is moved by bellows (2 groups - main and reserve). When the water overheats (from 95 to 100 °C), they are pressed by a heat-sensitive liquid coming from the sensor flask through a capillary tube. The design of the safety element is shown in the figure:

The temperature valve is included in the piping of a solid fuel boiler in three ways:

- with cooling through the water circuit of the heat generator;

- the same, through a special emergency heat exchanger;

- coolant discharge with automatic replenishment.

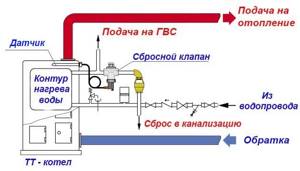

The first diagram, shown below, is used for double-circuit heating systems that heat water for domestic hot water. When a sensor mounted under the casing of a TT boiler acts on the mechanism, hot water from the circuit is drained into the sewer, and cold water from the water supply takes its place. Whatever the causes of the accident, such a flow system will quickly cool the boiler jacket and prevent consequences.

The DHW coil of a double-circuit boiler can serve as both a heater and a cooler in case of overheating. For protection, just connect the thermal valve according to the diagram

Note. The publication uses diagrams from the CALEFFI brand, taken from the manufacturer’s official resource.

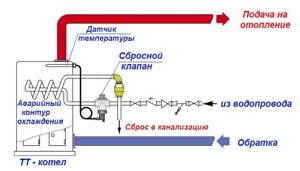

The second scheme is intended for heat generators with a built-in emergency heat exchanger for cooling in case of overheating. Such units are produced by European brands Atmos, Di Dietrich and others.

For an example of connecting a discharge element through a standard heat exchanger, see the video:

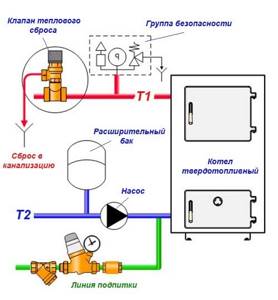

The latter scheme can only be implemented in conjunction with an automatic make-up system, since here the valve discharges coolant and not cooling water.

As you can see, the manufacturer allows the installation of two emergency devices - for pressure (safety group) and for temperature (relief valve)

Warning. It is not recommended to use automatic make-up for wood-burning heaters with a cast iron firebox. The latter is afraid of temperature changes and can crack if a large amount of cold water is supplied to the return line.

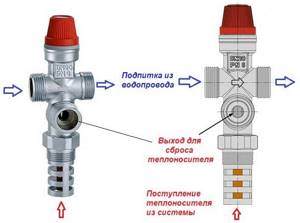

Combination valves with system make-up

This bright representative of emergency valves is similar in principle to bypass valves and performs 3 functions at once:

- Discharge of overheated coolant from the boiler tank based on a signal from an external sensor.

- Efficient cooling of the heat generator.

- Automatic replenishment of the heating system with cold water.

The picture above shows the design of the product, where you can see that there are 2 plates installed on one rod, which simultaneously open 2 passages: the boiling coolant is discharged through the first, water flows through the second in the opposite direction and replenishes losses. The connection diagram for a combined bypass valve with a solid fuel boiler looks like this:

Note. If it is necessary to use such a device to cool a TT boiler with a cast iron heat exchanger, then the flow must be organized through an open expansion tank or an indirect heating boiler.

A bypass valve with a triple outlet works on the same combined principle, only it is built directly into the coolant supply pipeline near the heating unit. The bellows is located in the part of the body placed in the pipe. The discharge is carried out through the lower pipe, and a water supply and a make-up line are connected to the two upper ones. Such products are used when there is not enough free space in the boiler room.

This relief valve is designed to be installed in the supply line.

Safety valves and their description: features of pressure regulation and settings

Sometimes unpleasant circumstances arise when the heating system malfunctions and the pressure begins to fluctuate. If the pressure is not regulated, the consequences can be dangerous. To prevent this from happening, the heating system and hot water supply system should be equipped with safety valves. What they are and how they work – we will tell you in this material.

Types of safety valves

In a heating system, a safety valve performs a protective function to prevent high pressure. This is especially important for steam boilers.

Blood pressure rises most often due to the following reasons:

- failure of automatic pressure control systems;

- a sharp increase in ambient temperature and the appearance of steam.

Safety products are mainly of two types:

- spring;

- lever-load.

In lever-load structures, the action of pressure on the spool is counteracted by a load, its force is transmitted through the lever to the rod. It moves along the length of the lever, and in this way you can adjust the force of pressure of the spool against the seat. Then it opens when the working medium begins to press on the lower part of the spool with a force greater than the force of the lever pressure and the water leaves through the pipe.

And spring safety units operate using an electromagnetic drive . A spring exerts pressure on the spool rod, and adjustment occurs by changing the degree of compression of the spring.

Small heating systems are best combined with spring products; their advantages in this case are as follows:

- compactness;

- the setting can only be changed when using the tools;

- the spool rod may have different positions;

- Possibility of combination with other products.

According to the principle of operation, safety valves are divided into the following:

- direct action devices;

- indirect;

- two-position.

A direct-acting safety valve can only open under pressure from the working medium, while an indirect safety valve can open only under the influence of a pressure source.

And according to the type of lifting the constipation, the devices are:

- low-lift;

- medium-lift;

- full lift.

Manufacturing materials

Safety products can be made from the following materials:

- brass;

- steel;

- Cink Steel;

- stainless steel

The safety brass coupling valve for the boiler is threaded on both sides and has a gasket on the inlet side. The mechanism is spring-loaded. External pressure can increase the blockage. After assembling the structure, it is pressurized, so this type of valve is very reliable and affordable.

can also to protect against backflow pressure.

Features of three-way valves

The purpose and operating principle of three-way safety valves is somewhat different from other options, and here are their key differences:

- use is permissible in low-temperature heating systems for media cooling;

- it is possible to adjust the product manually or using an electric drive;

- the presence of one inlet and two outlets;

- To regulate the flow, there is a special valve in the form of a ball or rod that directs it to the desired hole.

Such valves are most often used in heating systems that include “warm floors”. In this way, the water for heating the floors will be much cooler than the water in the radiator.

For the manufacture of three-way safety valves the following is used:

Brass designs are most common when installing home heating systems, while steel and cast iron are more common in larger industrial installations.

It is also worth paying attention to the explosion safety valve, which can prevent the explosion of flammable gases or coal dust. They are made in such a way that if the substance explodes, only the membrane of the structure is damaged, and the pipeline remains unharmed.

This type of product operates automatically. Depending on the pressure, they are distinguished into several types:

- with pressure up to 2 kPa;

- up to 40 kPa;

- 150 kPa inclusive.

How to choose the right safety valve

When choosing a safety valve, there are a huge number of factors to consider. In particular, be sure to take the ambient operating pressure into account. If this pressure is higher than normal, then you need to choose a 2 bar product that can withstand such operating conditions of the product. In addition, you can choose an option with the ability to adjust the pressure so that you can adjust the required mode and find out the exact parameters, in particular, the nominal diameter.

There are a number of standards regarding the performance of calculations; you can also find special calculation programs on the Internet. You can do without calculations and take a design with a diameter no less than the diameter of the outlet pipe of your boiler, but such a calculation will not be accurate and cannot guarantee a high level of safety and performance.

In general, in order to choose the right product, you should consider the following parameters:

- decide on the type of product;

- with a size so that the pressure in the system does not exceed the permissible limits;

- It is better to choose spring-type products for your home;

- open devices are suitable only if the water goes into the atmosphere, and closed ones - if into the outlet pipeline;

- after calculations, you can determine whether a low-lift valve or a full-lift valve is suitable;

- calculate your budget.

Safety valve prices vary depending on the material and other features. For example, an Italian-made membrane structure can be purchased for about 4 USD , and a brass one - starting from 12 USD. There are also some valve models whose cost exceeds $100.

Safety valve installation features

When installing the valve, you must strictly follow all the rules that are listed in the regulatory documentation of the product. Also, the installation must be carried out taking into account the power and operating pressure.

But the key installation principles are:

- carry out preliminary calculations of structural elements;

- Installation is carried out on the supply pipeline next to the boiler;

- It is recommended to place a pressure gauge next to the valve;

- when using a spring design, the spring axis must be vertical and placed above the body;

- The lever of a lever-and-weight valve must be horizontal above the valve;

- in a hot water system, the valve must be installed at the highest point of the water heater at its outlet;

- diameters cannot be narrowed if the valve dimensions do not match the pipeline diameter and for other reasons;

- the connecting pipe should not be too long;

- after connecting to the pipeline, the pipes must be taken to a safe place;

- the valves are adjusted to 20 percent more than the operating pressure of the heating system;

- the check must be performed by forced opening.

We also must not forget that it is necessary to regulate and check the pressure at least once a year before the heating season.

How to set a safety valve

The valve must be adjusted at the installation site after completion of installation work and after the system has been flushed. Set the setting pressure, check the opening and closing pressure of the product.

The settings should be set slightly above the maximum operating pressure, which is permissible during normal operation of the structure. And the full opening pressure should not be higher than the minimum level of the weakest element of the system. The closing pressure must exceed the minimum permissible value.

The pressure in the spring structure must be adjusted by rotating a special screw that compresses the spring, and the lever structure is adjusted using the required mass of the load.

How to choose a relief valve

Of course, in terms of purchase and installation costs, a traditional blasting valve will be cheaper than temperature devices. It will easily protect a closed heating system connected to a gas, diesel or electric boiler, because in the event of an accident they stop heating almost instantly. Another thing is a heat generator using wood and coal, which cannot go out immediately.

To successfully select a thermal relief or overpressure valve, follow these guidelines:

- When using any energy carriers other than solid fuel, feel free to buy a regular blasting device.

- Study the documentation of your heat source or boiler (depending on what needs to be protected) and select safety fittings according to the maximum permissible pressure indicated therein. Most heating equipment is designed for a limit of 3 Bar, although there are exceptions - Lithuanian Stropuva boilers can withstand only 2 Bar, and some Russian units (among the inexpensive ones) can withstand 1.5 Bar.

- To effectively cool wood-burning heat generators in the event of an accident, it is better to install one of the thermal relief valves. Their maximum operating pressure is 10 Bar.

- In open systems with a TT boiler, pressure relief is useless. Select a safety product that operates at a coolant temperature of 95–100 °C, suitable for your unit and recharge method.

Advice. Refrain from purchasing cheap safety valves from China. Not only is it unreliable, but it also leaks after the first explosion.

In addition to models with fixed settings, there are valves with adjustable settings on sale. If you are not a heating professional, then you should not buy them, and there is no particular need.

Final tips

If you are keenly interested in the safety of the boiler room and the reliable operation of heating equipment, then we recommend that you carefully study the range when purchasing fittings. The fact is that new useful products are appearing on the market that cannot be reviewed within the scope of this article, but they may be useful to you.

Operating moment. Monitor the condition of safety valves in order to detect activation in time and understand the reasons. Direct the heat release devices into the sewer funnel with a burst of stream - an unexpected splash of water in the boiler room and wet footprints will make it clear that an emergency situation has occurred.

Sources used:

- https://kotle.ru/avtomatika/predohranitelnyj-klapan-dlya-kotla

- https://resant.ru/klapanyi-predohranitelnyie-parovyih-i-vodogreynyih-kotlov-tehnicheskie-trebovaniya.html

- https://otivent.com/predohranitelnyj-sbrosnoj-klapan-v-sisteme-otoplenija

How to set up a safety valve in a heating system - Engineering Systems

Sometimes unpleasant circumstances arise when the heating system malfunctions and the pressure begins to fluctuate. If the pressure is not regulated, the consequences can be dangerous. To prevent this from happening, the heating system and hot water supply system should be equipped with safety valves. What they are and how they work – we will tell you in this material.

Features of the mechanism and design

The safety brass coupling valve for the boiler is threaded on both sides and has a gasket on the inlet side. The mechanism is spring-loaded. External pressure can increase the blockage. After assembling the structure, it is pressurized, so this type of valve is very reliable and affordable.

can also to protect against backflow pressure.

Safety valve in the heating system. Scheme, selection, configuration

The safety valve in the heating system is a protective device for heat generators and other equipment, characterized by ease of operation. Its main function is to relieve unplanned loads that arise in various situations.

In addition, this device regulates the flow of coolant in the heating system. All other equipment is very dangerous, since the high pressure in the water jacket is considered explosive.

Source: https://in-service47.ru/kak-nastroit-predohranitelnyy-klapan-v-sisteme-otopleniya/