When installing autonomous heating, it is necessary to take care of the safety and reliability of the system. In order for the heating system to be provided with automatic safety control, it is necessary to install a protective element called an electromagnetic shut-off valve. This protective element is a shut-off valve that ensures the safety and automatic operation of heating equipment.

If any dangerous situation occurs, the valve automatically shuts off the fuel supply. Such situations can occur due to various factors: a drop in coolant or gas pressure, a gas leak, or a decrease in draft. Any of these factors is dangerous for the operation of the boiler. Therefore, an electromagnetic shut-off valve is necessary for the heating system, as it shuts off the fuel supply. In our article we will consider the types of shut-off valves and the principle of their operation.

Purpose and design of solenoid shut-off valves

Regardless of their purpose, electromagnetic shut-off valves differ from other types of protective valves. Since it is triggered by external energy sources. The solenoid shut-off valve can be for water or gas.

The valve is activated using sensors that issue a command. Opening and closing can be done remotely. Such valves are often used in everyday life, in the energy sector, as well as in the food and medical industries.

The solenoid shut-off valve is used:

But the solenoid valve is more in demand in the energy sector. It controls the flow of fuel.

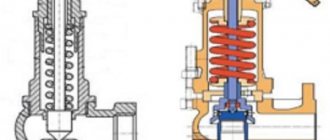

The valve may have one or more springs. They come in two types: disc and screw. In order for the springs to start working, it is necessary to use an electric or pneumatic drive.

The solenoid shut-off valve is a device that is equipped with an electric drive. The device contains latches that are controlled using electromagnets. The latches keep the springs charged. When a signal is given, the latches automatically release the springs and, therefore, the mechanism closes.

Classification of solenoid valves depending on the characteristics of the device

Solenoid valves are distinguished by a significant variety of design features, and therefore there is a wide field for classification.

They differ in the operating environment used in the systems where the devices are installed:

- water;

- air;

- gas;

- a couple;

- fuel, such as gasoline.

In difficult conditions where there is a possibility of an emergency, explosion-proof valve models are used

The composition of the working environment and the characteristics of the room determine the specific features of the design:

- ordinary;

- explosion-proof. Devices of this kind are usually installed at objects that are classified as fire and explosion hazardous.

According to control features, solenoid valves are divided into devices:

- direct action. This is the simplest design, characterized by reliability and speed. It does not have a pilot channel. When the membrane is instantly lifted, the device opens. In the absence of a magnetic field, a spring-loaded plunger is lowered, pressing the membrane. The direct-acting valve does not require a minimum pressure drop; it creates the necessary force on the spool rod due to the pulling force of the coil located at the top of the device;

- having membrane (piston) reinforcement. Unlike direct-acting devices, they use the transported medium itself to function as an additional energy supplier. These valves have two spools. The purpose of the main spool is to directly close the hole for which the housing seat is allocated. The control spool closes the relief hole(s), through which pressure is relieved from the cavity above the membrane (piston). This causes the main spool to rise and open the main passage.

Based on the location of the locking mechanism at the moment when the coil is de-energized, it is customary to divide the so-called pilot devices as belonging to a certain type:

- normally closed (NC). For NC valves, when the solenoid is de-energized, the passage for the working medium is closed. That is, a static position assumes the absence of voltage on the solenoid, the closed state of the device. Due to the difference in diameter between the pilot and bypass channels, the pressure above the membrane decreases in favor of the first. The pressure difference ensures that the membrane (piston) rises and the valve opens, remaining in this position as long as voltage is applied to the coil;

- normally open (NO). On the contrary, in valves of the normally open type, when the coil is de-energized, the working fluid can move along the passage in a given direction. By keeping the NO valve closed, a constant voltage supply to the coil must be ensured.

A normally closed valve shuts off the supply of the working medium in a de-energized state

Note! A number of modern modified models provide that the device, if necessary, can be reconfigured, turning it, as needed, into either an open type or a closed type valve.

There are also models of the device that provide for switching from the open position to the closed position and in the opposite direction when a control pulse is applied to the coil. Such an electric valve is called bistable. To ensure operation, such a solenoid device requires a pressure differential and a direct current source. Depending on the number of pipe connections, solenoid valves are usually called:

- two-way. Such devices have one inlet and outlet pipe connection. Two-way devices come in both NC and NO types;

- three-way. Equipped with three connections and two flow sections. Can be produced as NZ, NO or universal. Three-way valves are used to alternately supply pressure/vacuum to control valves, single-acting cylinders, and automatic drives;

- four-way. Four to five pipe connections (one for pressure, one or two for vacuum, two for the cylinder) ensure the operation of double-acting cylinders and automatic drives.

Types of electromagnetic shut-off valves. Principle of operation.

There are direct acting valves. In this form, the mechanism closes under the action of an electromagnetic drive. And the medium is cut off from both sides of the pipeline. There are also valves of the normally closed type. In this type, the valve operates under the influence of electromagnetic forces. If they are missing, the valve closes. A normally open type valve is open without any influence of electrical voltage. And closing is carried out using an electromagnetic pulse.

There are also solenoid pilot shut-off valves. They close under the action of the pilot. This mechanism works due to the pressure difference that occurs before and after. Once the required value is reached, the mechanism is activated and thus the valve closes. These valves are used in gas heating. They are normally closed and normally open. They can operate from an electromagnetic pulse.

There is another type of solenoid valve. Two normally closed valves of different nominal diameters are combined into one, which is called a two-port solenoid valve. Such valves can control fuel flow and are used for viscous liquids.

And solenoid valves with a rotary damper are used to shut off liquid fuel at a remote level. Such valves were manufactured to prevent the leakage of hydrocarbon gases. Solenoid valves with a rotary damper operate on the pressure difference between the outlet and inlet pipes. Such valves are installed on containers where gas is stored.

Using solenoid valves, you can remotely control the operation of the heating device. And also create automatic safe use. When using such a protective element, you can leave heating equipment unattended, as well as control it remotely.

Electromagnetic shut-off valves for heating boilers and their types

The autonomous heating system must be reliable, safe and “independent”. To ensure automatic control of safe operation, it is necessary to install a protective element - an electromagnetic shut-off valve.

An electromagnetic shut-off valve is a shut-off valve involved in ensuring the safe and automatic operation of heating equipment. The purpose of the valve is to shut off the fuel supply when a dangerous situation occurs.

An emergency situation in the operation of an autonomous heating system can occur from various factors: a drop in gas or coolant pressure, a decrease in draft intensity, a leak of flue or combustible gas. Each of these situations is dangerous and continued operation of the boiler is unacceptable, therefore the automatic protection system sends an electromagnetic signal to the shut-off valve. After this, the fuel supply to the boiler is stopped.

Types of solenoid valves

Electromagnetic shut-off valves can have various design features.

A direct acting solenoid valve is a mechanism that closes under the influence of an electromagnetic drive. The medium is cut off from both sides of the pipeline. They can be of the normally closed type - this means that the valve operates under the constant influence of electromagnetic forces; if they disappear, the valve closes.

A normally open valve is in the open state without electrical voltage. Closing occurs from an electromagnetic pulse.

Read about the operating principle and features of PB pellet burners in the article.

You can find out how to make an induction heating boiler by following the link -

Also read about solenoid shut-off valves.

The valves can be used in gas and liquid fuel heating systems.

Electromagnetic pilot shut-off valves are closed under the influence of an additional mechanism (pilot). It works due to the pressure difference before and after itself. When the set value is reached, the mechanism is activated and the valve closes.

The pilot valve can be operated by an electromagnetic pulse, like a direct acting valve. Such valves can be normally closed or normally open and are used in gas heating systems.

Double-port solenoid valves are two normally closed valves of different nominal diameters. They are used for viscous liquids and are capable of producing dosed fuel supply.

A butterfly valve solenoid valve is used to remotely shut off the liquid fuel supply.

Bottom high-speed solenoid valves are designed to protect against leakage of hydrocarbon gases. They are installed on gas storage tanks, and their operating principle is based on the pressure difference between the inlet and outlet pipes.

Electromagnetic valves make it possible to provide remote control of the operation of heating equipment, as well as automatic safe operation.

Main characteristics of shut-off valves:

- Type of transported medium and its consumption.

- Conditional pass.

- Medium pressure.

- Ambient temperature.

- Connection type.

Advantages of shut-off valves:

- Implementation of remote control of heating equipment.

- Implementation of automatic localization of emergency situations.

Disadvantages of shut-off valves:

- To ensure uninterrupted operation, it is necessary to install an additional power source.

- Installation of the valve on a gas pipeline is possible only with the participation of a qualified specialist.

Read about the causes of malfunctions of domestic heating boilers here.

On how to deal with scale in a boiler, you will find information at the link -

Also read about the prevention and repair of diesel burners.

Electromagnetic shut-off valves ensure safe and automatic operation of heating equipment. Their use makes it possible to leave heating boilers unattended and carry out remote control.

Advantages and disadvantages

The advantages of valves include:

- Automatic signal in case of emergency.

- Heating equipment can be controlled remotely.

But in addition to the advantages, solenoid shut-off valves have the following disadvantages:

- You cannot install the valve on the gas pipeline yourself. To do this, you must use the services of a qualified technician.

- In order for the device to operate without interruption, it is necessary to install an additional power source.

Types of shut-off devices

The classification of locking devices is based on several key parameters. Based on their operating principle they are divided into:

- Normally open - in the normal state, the devices are in the open position, freely passing the current of the working medium. When the actuator is activated, the valve closes, stopping the flow of water or gas.

- Normally closed - before an emergency occurs, the valve is in a closed state, and when the actuator is activated, it opens and releases liquid or gas. Some types of devices require manual opening of the valve.

Based on the type of system and operating medium, shut-off valves can be classified into devices for water and gas. Valves for shutting off gas are divided into single-seat and double-seat. The first type of shut-off valve closes the system on only one side of the pipeline when gas extraction stops. Double-seat valves block the gas flow on both sides of the gas pipeline when the pressure in the system rises/falls.

We recommend that you read: Fittings for connecting a heated towel rail

Shut-off valves for liquid working media are divided into four types:

- checkpoints;

- corner;

- single saddle;

- two-saddle.

According to the method of closing, valves are also divided into four categories:

- devices that close the flow of the working medium using a load;

- devices with a spring mechanism;

- devices with pneumatic drive;

- valves with electromagnetic drive.

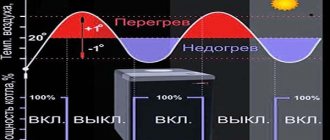

Important! Modern shut-off valves operate on average 10-15 seconds after an emergency occurs. But when choosing a device, you need to pay attention to the response speed, because... You can mistakenly buy an old type device, which works much slower and is less airtight.

Installation of the device

Before installing the valve, it is necessary to select a place where free access to the device will be provided. This requirement must be adhered to in order to freely use the solenoid valve. The inlet and outlet parts of the pipeline must be located at the same level. And also these parts must support the weight of the device. Install the equipment taking into account the arrow pattern on the housing. The arrow must correspond to the direction of water movement. It is necessary to clean the pipes inside. Then, after installing the valve, you need to check the external and internal leaks.

Purpose of shut-off valve

The valve is an automated mechanism with a gate valve connected to an electromagnetic or pneumatic actuator. When the actuator is activated, the internal valve completely blocks the passage opening of the valve, stopping the movement of the working medium. The main part of the shut-off valve is a spring, which releases potential kinetic energy when the electric drive is activated and moves the device to the operating position.

This is interesting to know! An example of a mechanical shut-off device, which can be considered an older analogue of a shut-off valve, is a cast iron valve, which also blocks the flow of the working medium, but without the participation of automation using a flywheel.

As the name suggests, the valve completely “cuts off” the section of the pipeline where an emergency situation occurred, preventing water or other liquid from moving further. In practice this is necessary for:

- preventing a large leak of water, gas or other important resource;

- protection from chemical contamination of the territory;

- preventing damage to economically significant equipment, machinery, property;

- protection from damage to the life and health of enterprise personnel and civilians.

Most often, a shut-off valve can be seen in hot and cold water supply systems, gas supply, energy and petrochemical industries, and at various technological enterprises. In the domestic sphere, shut-off valves are installed on heating and plumbing equipment - heating boilers, in the area where filters, pumps, and heat exchangers are connected.

We recommend that you read: How to correctly and reliably connect a metal pipe to a plastic one?

What to look for when choosing a valve

A shut-off valve should be selected by a person with an engineering education, because It is difficult for the average person to navigate the variety of devices. When choosing and installing a shut-off valve, professionals are guided by the following parameters:

- The degree of tightness is an important characteristic for an engineering system. Modern types of devices are equipped with twisted sealing gaskets that prevent leakage of liquid and gas.

- Response speed is the most important parameter of device operation, especially critical for high-pressure engineering systems. The faster the valve operates during an emergency, the less water or technical fluid will be lost.

- The material of manufacture is steel or other durable alloys, as well as additional oil seals and seals. The most important thing is the material’s ability to withstand high temperatures and pressure without losing physical and technological properties.

- Type of work environment. This can be clean, slightly or heavily polluted water, oil products, gas and other media. Modern cut-off valves are designed in such a way that they are not affected by the presence of mechanical particles in the water, as well as the density, viscosity and fluidity of the working medium.

Attention! Price is a secondary parameter when choosing shut-off equipment, especially in technically complex and critical engineering systems. Savings are fraught with a reduction in the service life and service life of the equipment.

The price range of shut-off valves depends on the manufacturer, as well as the size of the model. Small devices with an electromagnetic drive up to 20 mm can cost an average of 1.9-2 thousand rubles. Valves up to 100 mm can cost the buyer more - from 20 to 30 thousand rubles.

We recommend that you familiarize yourself with: Dimensions and types of PVC sewer pipes and adapters for connecting them

Based on the type of device, choosing a valve is more complicated, because Each type of engineering system has certain operating parameters that affect the shut-off equipment. For example, for simple plumbing systems, you can choose a simple straight-through valve, which is enough to prevent water leakage in an emergency. But for systems in which water circulates under high pressure, it is better to choose a corner double-sided cut-off valve.