Today, having a heated floor in a house or apartment is far from a luxury and not uncommon. Any owner of a private house or apartment can easily buy and install it, either independently or with the help of specialists (depending on the type and method of fastening the heated floor pipes). Most often, people install such floors not for their own comfort, but for their children. In addition, the heat from the floor is evenly distributed over the entire area of the room in which it is installed. Nowadays, in markets and specialized stores, customers are presented with a wide range of different heated floors. Their differences are only in price and installation method.

Construction of polyethylene pipe

Reinforcement.

Almost all cross-linked polyethylene pipes have a complex multilayer structure. It could be:

- polypropylene;

- fiberglass;

- aluminium foil;

- perforated aluminum;

- solid aluminum sheet.

The reinforced layer is able to neutralize sudden pressure changes inside the PE-S pipe when used in a hot water or heating system.

The design of cross-linked polyethylene products provides for the presence of a reinforced layer both on the surface of the product and at various depths. If it is necessary to solder two or more pipes, the reinforcing layer is stripped to 1 cm.

Pipes made of cross-linked polyethylene for underfloor heating are practically not reinforced. This material is also called “pure”.

Oxygen barrier. The manufacturer also calls it a “diffusion barrier” or “anti-diffusion protection.” This layer is mandatory for all types of cross-linked polyethylene products.

The reason for its appearance in HDPE pipes is the ability of oxygen molecules to penetrate into the material through a three-dimensional lattice, as a result of which cross-linked polyethylene is slowly but surely destroyed.

The diffusion barrier can also be either inside or outside the pipe.

Advantages and disadvantages

Using a special device, you can quickly secure pipes

The advantages of anchor brackets include:

- high speed and ease of installation of products in comparison with other methods;

- reliability of fastening of pipe blanks;

- durability;

- relatively low cost.

The fastening element can be used to fix other types of pipelines that are not related to heated floors. Due to the presence of protective plastic teeth, the products in question are highly resistant to impact loads. The disadvantages of fasteners of this class include the complexity of installation on some types of water and electric heated floors.

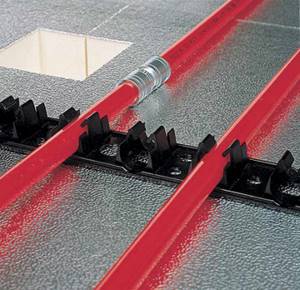

Expanded polystyrene boards with fixation

Option 1

A very creative way to install pipes. Since with the help of volumetric protrusions on the coating, pipes can be laid in any pattern as you wish. Despite the small distance between the protrusions, many people think that this is what will fix the pipe, but this is far from the case. For fixation, special clips are also used, which guarantee the reliability of a strong fastening of the pipe.

Advantages: The pipe is protected by special bosses from mechanical damage. Such a system can be freely purchased both on the market and in a specialized store.

Disadvantages: Quite a high price for all components. To fix the pipe, additional elements must be used.

Option 2

This installation method is very similar to the previous one, but there are significant differences. There are special protrusions on the coating that firmly fix the pipe without any additional equipment. You can fix the pipe in a very simple way: by carefully pressing the pipe between these protrusions.

Advantages: This method of attaching a pipe is considered very convenient and reliable. The slab is not damaged when moving across the floor. An excellent combination of functionality, quality and price.

Disadvantages: The cost is much higher than the earlier examples. Such a specimen is quite difficult to find in markets and specialized stores.

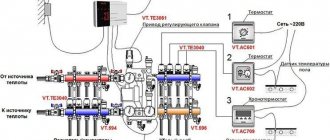

Collector connection diagram

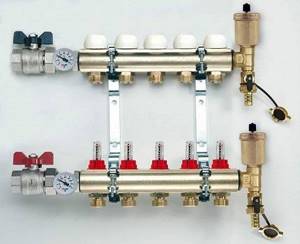

The choice of a ready-made mechanical or automatic collector model depends on the characteristics of the heating system.

The first type of control module is recommended to be installed for heated floors without a radiator, the second can be used in all other cases.

Valtec collector groups are the most popular. The manufacturer provides a 7-year warranty on its products. The installation diagram for the liquid circuit manifold is already included in the package of the finished mixing unit

According to the diagram, the assembly of the distribution comb for heated floors is carried out as follows:

- Installation of the frame. The following can be selected as the installation area for the collector: a prepared niche in the wall or a collector cabinet. It is also possible to mount directly to the wall. However, the location must be strictly horizontal.

- Connection to the boiler. The supply pipeline is located at the bottom, the return pipeline is located at the top. Ball valves must be installed in front of the frame. They will be followed by a pump group.

- Installation of a bypass valve with a temperature limiter. After this, the collector is installed.

- Hydraulic test of the system. Check by connecting to a pump, which helps build up pressure in the heating system.

In a mixing unit, one of the required elements is a two- or three-way valve. This device mixes water flows of different temperatures and redistributes the trajectory of their movement.

Shut-off valves and fittings are installed on both pipelines, return and supply, connected to the manifold installation, designed to balance the volume of the coolant, as well as to block any of the circuits

If servo drives are used to control the manifold thermostats, then the mixing unit equipment is expanded with a bypass and bypass valve.

Which way is better?

The choice of the best method is influenced by the quality of fastening and the price of the issue. For professional craftsmen who perform large volumes, convenience and speed of installation play an important role.

Fastening to reinforcing mesh has been used for a long time, its advantages are ease of installation and minimal costs. However, it is difficult to call the method convenient: you have to work all the time bent over, tying nylon ties with your hands. And the use of a grid does not cause unanimous approval. There is an opinion that it gradually cuts the plastic and over time the pipes begin to leak.

More and more craftsmen are resorting to working with a tucker, which allows them to produce large volumes of work in a short time. At the same time, the quality does not suffer compared to other methods.

The same can be said about the use of polystyrene foam mats with fixation. Time will tell which method will become the most common.

This video shows common installation methods

Alternative options for mounting heated floors

To fix heated floors, not only a bracket is used, but also other devices:

- Mats with bosses do not require additional fastening. They are easy to install and fix, and their thermal insulation qualities are above average;

- Masonry reinforcing mesh for pipelines is fixed with plastic and metal clamps. The design is reliable and highly durable;

- If the base is made of foam plastic, then the pipes are secured with an anchor bracket;

- Concrete base requires perforated tapes during installation;

- Wooden floors are usually heated with pipes installed on wooden modules.

Mats with bosses

Advantages of using mats with bosses:

- You can make a concrete screed directly onto the mats without making a protective layer. Cement does not enter into chemical reactions with mats that have a protective film on the surface;

- Easy installation - modules are assembled by hand;

- Pipe fasteners are not required; the bosses on the plates themselves firmly fix the pipeline;

- The reverse side with a relief increases thermal insulation, noise protection, and also makes it possible to build the system on an unleveled base.

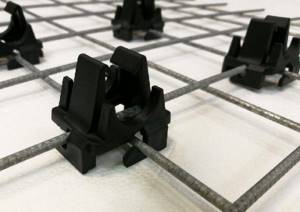

Reinforcing mesh

The concrete screed can be additionally strengthened with reinforcing masonry mesh. The design becomes several times more durable. To do this, the grid must be laid in a special sequence:

- Clamps made of plastic or silicone make the fastening easy and simple, so the installation of the pipeline will be completed in a few movements. Connections of this type are very reliable and do not break;

- The use of wire limits the installation process - strong tension should not be allowed, since there is a high risk of damage to the pipe;

- An iron clamp is a compromise between plastic clamps and wire. Iron fasteners are more expensive, but the installation process will be lengthy.

Having considered all the options, we can conclude that the installation of the water circuit pipeline is carried out on a reinforcing mesh using plastic clamps.

Perforated plates

The liquid line is laid on perforated plates. They are made of polystyrene foam and have a contoured surface with fixing elements or without special devices. What are the characteristics of the slabs?

- The thickness of the mat is 1-3 cm.

- Outline height 2.5 cm.

- The distance between the contours is 2-5 cm.

- The material can withstand high temperatures and changes in thermal conditions.

- Expanded polystyrene does not deform under the influence of a deep concrete screed.

- The mats will serve as additional thermal insulation and noise protection.

The pipeline is removed using a snail or snake. If the contour is located at a distance of 16-20 mm, then it reliably holds the line. The bosses fit around the pipes on the sides. There is no need for additional fastenings. If the distance between the circuits is greater than the outer diameter of the pipe, then it is necessary to take care of the mounting elements. Holes are provided in the bosses for staples.

The perforated surface may not have bosses that rise on the surface of the mat, but grooves. Their width corresponds to the diameter of the water circuit pipe. In order for the loop to turn without loads and to correspond to the bending radius, the mats are provided with perforations in the form of a loop.

If a reflective screen is not provided for the heated floor, then mats with a foil surface are chosen. The material has only one drawback, which is associated with the high cost of the product.

We recommend: What kind of substrate is needed under a laminate for a warm water floor?

Installation technique

Heated floor pipes are mounted on insulation - polystyrene foam

The most common option for using anchor brackets is the fastening of heated floors with elements having a standard size of 16 mm. Laying the structure with their help is organized according to the instructions, which prescribe the following sequence of operations on polystyrene plates:

- The floor base is cleaned of accumulations of dirt and dust, as well as of debris remaining after construction work.

- The floor surface is carefully leveled, and excessive differences in height are eliminated using a self-leveling mixture.

- After setting, a layer of polyethylene film is laid on a flat surface, used as waterproofing protection.

- Its individual pieces are placed one under the other, and the overlap areas are then sealed with construction tape.

- The surface is laid with a standard edge strip, on top of which polystyrene mats are laid out with a slight offset.

- The latter are fastened together using a special type of locks.

- Directly on the surface of the polystyrene coating, the thermal circuit is laid out.

Concrete base

The base of the room is most often made of concrete; the screed is not always covered with a layer of insulation. To fasten pipes to such a base, perforated tapes are used, the structure of which has special recesses for laying pipes.

The profile on a concrete base is fixed with self-tapping screws, the heating elements are installed with special fastening bars. The pipe can be secured to concrete using clips for the water circuit.

A plastic clip is installed to the concrete using self-tapping screws, and a pipe is placed on top of the structure.

For a diameter of 16 mm, staples are chosen with a larger size, and the arcs for connection are cut off. The pipe may wobble slightly when fixed, which is acceptable given thermal expansion.

The mounting method depends on the base

The choice of method for attaching the circuit depends on the base under the pipes. Let us dwell on the options for bases and methods of attaching underfloor heating pipes.

Mats with bosses

The use of mats with bosses provides the following advantages:

- The possibility of using a concrete screed over the mat without a special protective layer, since the cement will not react with the elements of the mat. The surface of the mat has its own protective film.

- Easy installation. Putting the modules together is not difficult.

- Simple pipe fastening. To secure the pipes, no fasteners are needed, since the slab bosses securely fix the pipes.

- Relief reverse. This provides several advantages at once: increased thermal insulation, sound insulation and the ability to use on uneven ground.

When using mats with bosses, there is no need to worry about how to attach the heating elements to the polystyrene foam.

Reinforcement mesh

A reinforcing mesh is laid on top of the concrete screed to add strength to the structure. When laying pipes on reinforcement mesh, the following fastening methods are used:

Fastening with plastic clamps is reliable and quick

- plastic clamps. Securing with silicone clamps is easy and simple, because the process of tightening the pipes takes place in a couple of deft movements. At the same time, the connections are reliable. It is impossible to break such a clamp.

- wire. Do not pull too hard, otherwise the pipe will be damaged.

- iron clamps. Average between the two previous methods, but it takes more time and the clamps are more expensive.

Conclusion: plastic clamps are suitable for attaching warm water floor pipes to reinforcement mesh.

Foam insulation

Anchor shackles

If the insulating layer consists of polystyrene boards, then special staples for a warm water floor made of plastic with pointed and hook-shaped teeth are used, which is why they are called anchors.

When using staples you need to be careful and careful. It is necessary to correctly calculate the distance between the pipes using foam plastic and only then proceed with fastening. It is not recommended to pull out staples and drive them into new places. It is possible to crumble and degrade the technical qualities of the thermal insulation material.

Concrete base

Often a concrete screed without an insulating layer is used as a base. In such cases, special perforated tapes are needed, which have special places in the structure for securing pipes. The profile is fastened to the concrete base with self-tapping screws, and the circuit of heating elements is attached to the fixing rail.

To attach pipes directly to a concrete base, use clips for warm water floors. A plastic clip is attached to the concrete using a self-tapping screw, and a pipe is placed on the clip. For example: if the pipe for a water heated floor is 16 mm, then the clip has a larger diameter and a cut-off arc for connection. Don't be alarmed if the pipe is slightly loose on the clip. The main thing is that the contour does not move during operation.

Conventional insulation with a system of wooden logs

Wooden modules

To heat wooden floor coverings, use a special wooden module that is installed on top of the joists. It turns out that a water circuit of the pipeline is laid on top of any type of insulation, securing the pipes to special wooden logs with grooves. And there is no need to rack your brains over the process of forming the contour, because the distances between the grooves have been calculated.

The fastening method is selected depending on the base for laying the pipeline. It is necessary to take into account all the nuances during the design process in order to complicate installation.

Mounting rails

The liquid line circuit can be strengthened using mounting bars. They represent a single system of anchor brackets. The material is produced in the form of tapes.

- The tires are placed on the surface of the insulation in increments of 1 m.

- They are attached to the concrete surface using dowels.

- They are installed on the thermal insulation material using mounting brackets.

- The locks are connected in increments of 5 cm. The size is chosen according to the pipe diameter of 16 mm or 20 mm.

We recommend: Do you need an anchor bracket for a heated floor?

Installation of the circuit using tires is quick. Among the disadvantages of this fastener for heated floors is the insecurity of the pipe bend. To fix the contour at the turning points, contours are laid or reinforced mesh is used.

Before installing the floor line, a design is carried out. It determines the pipeline laying step. In places where household appliances or furniture are supposed to be installed, the distance between the hinges will be greater.

On the active area, the recommended step is 15 cm. To determine the distance between turns, it is necessary to calculate the power of the heating system and the number of pipes. Calculations can be performed using an on-line calculator.

Choosing the optimal step

After selecting the material and method of pipe placement, you need to determine the distance between adjacent turns of the circuit. It does not depend on the type of placement of coolants, but is directly proportional to the diameter of the pipes. For large sections, too small a pitch is unacceptable, just as for pipes with a small diameter, a large pitch is unacceptable. The consequences may be overheating or thermal voids, which will no longer characterize the heated floor as a single heating system.

Video - Warm floor "Valtek". Installation instructions

A correctly selected step affects the thermal load of the circuit, uniform heating of the entire floor surface and the correct operation of the entire system.

- Depending on the diameter of the pipe, the pitch can range from 50 mm to 450 mm. But the preferred values are 150, 200, 250 and 300 mm.

- The spacing of coolants depends on the type and purpose of the room, as well as on the numerical indicator of the calculated heat load. The optimal pitch for a heating load of 48-50 W/m² is 300 mm.

- For a system load of 80 W/m² or more, the pitch value is 150 mm. This indicator is optimal for bathrooms and toilets, where the floor temperature must be constant according to strict requirements.

- When installing heated floors in rooms with a large area and high ceilings, the coolant laying step is taken to be 200 or 250 mm.

Warm water floor installation project

In addition to a constant step, builders often resort to the technique of variable placement of pipes on the floor covering. It consists of more frequent placement of coolants in a certain area. Most often, this technique is used along the line of external walls, windows and entrance doors - maximum heat loss is noted in these areas. The value of the increased pitch is determined as 60-65% of the normal value, the optimal value is 150 or 200 mm with an outer pipe diameter of 20-22 mm. The number of rows is determined during the laying process, and the calculated safety factor is 1.5.

Schemes for enhanced heating of external walls

Variable and combined laying steps are practiced in external and peripheral rooms due to the urgent need for additional heating and large heat losses; in all internal rooms the usual method of placing coolants is used.

The process of laying underfloor heating pipes is carried out in strict accordance with the project

Specifications

Anchor clips in the category of fixing devices are classified according to the typical size corresponding to the width of their base fastening. This parameter is decisive when familiarizing yourself with their technical characteristics. According to the existing classification, they are divided into samples of the following type:

- U-shaped brackets of the STK brand, suitable for fastening pipe blanks of various diameters;

- plastic anchor fasteners used for fixing pipes of type “Du 16” in the “water heated floor” system;

- the same products designed for pipe size “DN 20”.

In the practice of installing underfloor heating systems, 16 mm anchor brackets for underfloor heating are especially common; they are optimally suited for attaching polystyrene foam insulating flooring slabs. The dimensions of such a bracket in height are about 51 mm. It contains double hooks in its design, thanks to which the fixed pipe is securely fastened and does not jump out of the insulating material.

Anchor products are suitable for installing underfloor heating from such well-known manufacturers as Uponor, Rehau, KAN and others. The approximate consumption of U-shaped staples of the STK brand is 2 pieces per linear meter. They are made in the form of red clips, which contrast well with the gray plastic pipes.

Mounting options and fixation methods

Effective operation of underfloor heating is possible provided that the pipes are correctly installed and connected to the central heating system. The key task of the contractor is to correctly distribute the linear footage of the pipeline on the surface of the subfloor to ensure uniform heating of the floor covering.

As a rule, pipes are installed in a “snake” pattern, i.e. First, the pipe goes in one direction, then makes a 180-degree turn and is laid in the opposite direction so that the two sections are located relatively close to each other (up to 30 cm).

This way, the coolant energy is effectively distributed over the entire floor area in the room. The pitch between pipe branches depends on its thickness, material, flexibility and intended heating mode. Thin plastic pipes made of polypropylene or polyethylene are laid in frequent increments.

Before installing a heated floor, prepare a rough surface - a concrete screed or a wooden plank floor, on which film waterproofing is laid. One of three types of underlay is placed on the subfloor:

- reinforcing metal mesh;

- polystyrene boards;

- mounting rails.

A special fixing substrate is a mandatory requirement for the correct installation of underfloor heating pipes, otherwise the pipes may move during the process of pouring the cement screed, and the system will not work correctly.

Reinforcement mesh - advantages and disadvantages

Metal reinforcing mesh is the most popular way to fix underfloor heating pipes. It is sold in the form of identical lengths or in coils, and is laid on a concrete floor. Pipes are distributed along it and fixed using various fasteners.

The advantage of this method is the availability of reinforcing mesh and its low cost in construction stores. The disadvantage is the labor-intensive installation process and the high risk of damage to plastic pipes.

We recommend that you familiarize yourself with: Metal hose in a sheath with PVC insulation to protect the cable

Pros and cons of polystyrene backing

Polystyrene boards are shaped products with protrusions equidistant from each other - bosses, between which pipes are laid. There are various shapes and configurations of bosses.

The main advantage of this installation method is the speed and ease of installation of pipes, which can be arranged in any way: “snail”, “snake” and other patterns. Thanks to the protruding elements of the polystyrene plates, the pipes are protected from mechanical damage. Disadvantages include the high cost of materials and the need to use additional fasteners.

Mounting rails for laying heated floors

Tires are long products with special clamps with which pipes are secured. With their help, you can easily and quickly install flexible plastic pipes that will be protected from damage.

Compared to reinforcing mesh, mounting bars are less labor-intensive in terms of installation, but their disadvantage is that they are rarely available for sale and can be quite expensive.

In addition to the substrate, various fasteners are used to firmly fix underfloor heating pipes:

- Plastic clamps or cable ties are simple products that form a loop covering the pipe and the bars of the metal reinforcing mesh. This is the simplest and most affordable method of fixation, but it is only suitable for reinforcement substrate.

- Plastic clamps with notches are products designed for fastening pipes to a polystyrene backing. They are installed on top of the pipes and pressed into soft polystyrene, held in place by spacers included in the sharp tips.

- Plastic clips are products in the form of a small horseshoe with a flat, level base on which they are installed. The pipe is laid and held motionless.

- Metal clamps in the form of a loop that matches the diameter of the pipe. Such products have a hole for a fastening element - a nail, self-tapping screw or bolt - for fixing on the rough surface.

We recommend reading: Why heating pipes in an apartment make noise or hum, and how to fix it

Velcro

suggests using the Rautherm Speed system as a fastener for the floor water line. It consists of a covering on which there are small loops and a tape with hooks on it. The system works on the Velcro principle. Purchase the fastening system from dealers in Moscow and St. Petersburg.

A tape is wound around the pipe and placed on mats with loops. The hooks fit into the loops and fix the contour in a certain place. If necessary, the location of the highway can be adjusted.

The mats have a thickness of 3 mm. They are an additional thermal insulation material for the floor and prevent noise from entering the room.

On the outside they have a sticky surface, which is protected with tape. When laying the mats, the tape is disconnected and the roll is rolled out over the floor surface. The material is designed for pipes with a diameter of 14-20 mm. Withstands pressure 6 bar, temperature 95 0C. The installed system is filled with concrete screed.

A variety of devices are used to secure the floor water main pipeline. Methods are selected based on installation efficiency and product cost. Small costs will be required to lay the highway using reinforced mesh and mounting tape.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- Rating of manufacturers of heated floors for tiles

- How to choose a boiler for underfloor heating?

- How to install electric heated floors under tiles?

- Features of Korean heated floors

- Do you need a mixer for underfloor heating?

- How to install heated flooring under a shower stall?

Fasteners for heated floors

Let's start with easier-to-install roll-on electric floor heaters. These are cable or carbon mats and film heaters (also carbon or bimetallic). They are rolled out over a layer of insulation. They are usually secured with tape. Only for film floors they often use double-sided tape, and for mats - regular tape. In some cases, the cable mat mesh is shot with a staple gun or a construction stapler.

Scotch tape is a universal material used to attach some materials for heated floors.

Fastening underfloor heating pipes

Laying pipes or heating cables requires special clamps. They may be different. The design and installation method differ, which largely affects the installation speed. So, what and how can you secure the pipes or cables of a heated floor:

- Lay a metal mesh with a step between the rods of 5 cm. The step is not important, it’s just more convenient to calculate the step of laying a pipe or cable. With this method, the pipes are attached to the cells with plastic clamps or pieces of wire.

- Single clips (pictured below right). They are used together with a heat insulator on which markings are applied. The same grid with a side of 5 cm, but drawn. Each fastener is fixed in the subfloor according to the installation diagram. Even more painstaking and lengthy work. Such fasteners work well only when using high-density polystyrene. Then the fastener is inserted by hand or with a special machine, grabbing the pipe or cable.

- Mounting tapes (pictured top left). They can be metal or polymer. In metal ones, the petals are bent and cover the cable or pipe. The plastic ones have grips located quite often. The pipe or cable is simply pressed into them. These planks are attached in increments of 40-50 cm. Not a bad option: they are inexpensive, installation proceeds quickly.

- Expanded polystyrene boards with molded fixing elements (pictured below). These are the most expensive retainers. But two layers of the “pie” are combined at once: thermal insulation (plates are available in thicknesses of 30 mm or more) and fasteners. The shape of the fastening element depends on the manufacturer, but in any case, pipes and cables are fastened quickly and easily.

It’s up to you to decide which fasteners to use for heated floors. The fastest way is polystyrene plates, the cheapest is mesh. But a word of warning: when choosing fasteners for a water floor, keep in mind that you will need to fill the water heated floor system before pouring the screed. When using plastic mounting tape, there is a possibility that the pipe will break out of its sockets without a tie. There is such a possibility in polystyrene plates, but this happens extremely rarely. From this point of view, a grid is better.

Description of anchor shackle

Anchor brackets hold pipes in position

Fastening of pipes to the floor surface using special brackets is organized according to time-tested methods, which are based on a manual or semi-automatic principle. These methods are especially effective on turns or bends of thermal contours with a significant length of laid routes. On extended sections of the pipeline, the fixing points are located at a distance of about 50 cm from one another, and in fracture zones this interval is reduced to 10 cm. Compliance with this step allows you to fasten the pipes efficiently and reliably, significantly extending their service life.

Anchor shackles are made of material that is highly durable and can withstand significant overloads. The design of the fastening element includes special spacers, thanks to which the teeth and clamps of the pipeline are fixed as reliably as possible. Once the installation of such products is completed, it is almost impossible to release them without an external tool.

Types of heated floors

Today there are three main types of underfloor heating systems:

- water;

- electric;

- infrared.

A water heated floor operates on the basis of water pipes, which are laid directly under the finished floor covering. The source of the coolant is hot water from the heating system (less often, from a separate heating device - boiler and boiler). For installation and connection of pipes, metal-plastic and plastic pipes are used, which are connected to the heating outlet pipeline.

Electric underfloor heating is based on the so-called. heating cable. By passing current through itself, the wire converts its energy into heat due to the high resistivity of the conductor. Any cable is not suitable for installing an electric heated floor - you need a special wire with a conductor of the required thickness, as well as with good insulation.

Infrared heated floors are the rarest variety. It is installed on the basis of special roll films, in which special heating elements are built-in. When exposed to current, they produce infrared radiation, generating heat.

Next, we will talk specifically about the water type of heated floor, which is most often preferred, because... it is much easier to connect pipes to an existing heating system in a house or apartment.

We recommend that you read: How to choose a pipe cutter for installing copper pipes

Insulation on wooden joists

The heating system for floor coverings made of wood requires installation on wooden modules. Each module is placed on logs, so the water circuit is always on top of the insulation.

The pipes are fastened into special grooves, so the installer does not have to think about how to form a heating circuit - the distance between adjacent grooves has already been adjusted. Fixation and type of fastening are selected based on the base, which is located under the pipeline. It is important to take into account all the features so as not to complicate the installation processes.

Reinforcement mesh

The most inexpensive element for attaching a floor water line is reinforcing mesh. Select a material with a cell of a certain size. It depends on the step length with which the pipeline is laid: 10*10 cm, 15*15 cm.

Among the advantages of this fastener, the reliability of the fittings is noted. It serves as additional reinforcement for the concrete screed, which is formed for the water-heated floor.

- The pipes are secured using staples or tape. The brackets are made of heat-resistant plastic. They have spines pointing downward; securely hold the pipe in place.

- The staples are installed in a certain order on the entire surface of the reinforcing mesh. They have hooks on the underside. With their help, fastening to the fittings is made. The step between staples is 30-40 cm.

- In places where the pipe bends, it is necessary to place 3 staples. One is designed to hold the pipe in the center, the others provide a certain bending radius.

- The outline is drawn with a snake; push the pipe into the fastener with your foot. Use soft shoes.

Instead of staples, the line is reinforced with plastic tape. It has teeth on the inside. There is a loop at the end. The tape is wrapped around the pipe and inserted into a loop. In this case, the teeth are held by the edges of the loop, securely fixing the contour.

The work is more labor intensive. In this case, the plastic comes into contact with the reinforcing mesh. When using staples, the product is placed on a slight elevation. The grid remains at the bottom.

Using a tucker

Heated floor pipes can be secured using a tucker. This is a mounting stapler. It has a long handle and a mounting location for staple cartridges. One cassette contains 100 staples. They are metal, made of aluminum alloy.

- Before installing the pipeline, markings must be made. A pipe is laid across it.

- The tucker is adjusted to a certain pipe diameter.

- The work is carried out by 2 people; one lays the contour, the other strengthens it with a tucker.

- The staples are attached to the insulating material. Recommended pitch is 30 cm.

- At the point where the contour turns, 3 brackets are installed that hold a certain bending radius.

The installation of the main line is quick, but it requires careful preparation. It will be difficult to detach the bracket from the floor. This can damage the insulation material.

Features of cross-linked polyethylene

Cross-linked polyethylene is produced either physically or chemically. When it is created, units of ethylene molecules form a spatial (three-dimensional) network with cells through cross-links. Cross-linked polyethylene as a material is designated PE-X. According to the production method, they are distinguished: PE-Ha, PE-Xb, PE-Xc, PE-Xd.

PE-Ha is a polymer that is formed when heated using peroxides. PE-Xb polyethylene is obtained by moisture treatment with a catalytic agent and implanted silane. PE-Xc is a material formed after electron bombardment of polymer molecules. PE-Xd is extremely rare and is produced using nitrogen technology.

PE-Ha cross-linked polyethylene pipes are best suited for underfloor heating.

There are several types of cross-linked polyethylene pipes, they differ in the manufacturing method

Advantages and disadvantages

Pipes made of cross-linked polyethylene for heated floors have a number of advantages:

- Elasticity. This allows you to use the most optimal level of bending when laying, without the risk of subsequent cracking and fractures. Rehau products are considered to be especially high quality in this regard.

- Environmentally friendly. Cross-linked polyethylene contains no harmful components that would be released during heating. This guarantees safety in laying heated floors inside residential premises.

- High combustion temperature. The material begins to melt only after reaching a temperature of +400 degrees. As a result of the breakdown of the substance, water and carbon dioxide are formed, which are completely non-toxic.

- Excellent performance characteristics. The system, made of cross-linked polyethylene, is not afraid of rotting, corrosion and chemical influences. All this is the key to long-term and flawless operation of the water heated floor.

- Frost resistance. In the event of a significant drop in temperature, polyethylene products are not deformed.

- Sound-absorbing abilities. Thanks to this, there is no noise from the coolant circulating inside the circuit.

As for the weaknesses of polyethylene, they usually indicate the need for competent installation work. For example, it is recommended to securely fix turning areas, because this material does not hold the curved configuration given to it very well. In addition, the resistance of polyethylene products to direct sunlight is not very good.

Laying the contour must be done as carefully as possible, avoiding any damage to the protective layer

Cross-linked polyethylene or metal-plastic

Cross-linked polyethylene pipes and metal-plastic pipes are the main competitors when it comes to installing plumbing, heating systems or heated floors. They have a lot in common. Both types of pipes are quite flexible, durable, resistant to corrosion and relatively easy to install - you certainly don’t have to weld anything. True, it is still easier to install metal-plastic pipes than PEX pipes, with which you need to be extremely careful

Metal-plastic pipes have a slightly higher thermal conductivity coefficient (0.45 versus 0.38), but they will not survive freezing inside the coolant. PEX pipes, after the water in the system has melted, can be used as before. Moreover, some types of PEX pipes easily regain their shape. Resistance to high temperatures and pressure is high for both types of pipes: metal-plastic can withstand pressure up to 25 atm at a temperature of 250C, can be operated at coolant temperatures up to +950C with a short-term increase to +1200C, however, the maximum pressure is 10 atm. Thus, the performance characteristics are quite comparable with the similar parameters of cross-linked polyethylene pipes, which we cited above.

The choice depends mainly on the operating characteristics of the water supply system and the budget. The range of prices among pipes, even within the same group, is significant, but PEX pipes are often cheaper than metal-plastic pipes.

Features of cross-linked polyethylene

Cross-linked polyethylene is produced either physically or chemically. When it is created, units of ethylene molecules form a spatial (three-dimensional) network with cells through cross-links. Cross-linked polyethylene as a material is designated PE-X. According to the production method, they are distinguished: PE-Ha, PE-Xb, PE-Xc, PE-Xd.

PE-Ha is a polymer that is formed when heated using peroxides. PE-Xb polyethylene is obtained by moisture treatment with a catalytic agent and implanted silane. PE-Xc is a material formed after electron bombardment of polymer molecules. PE-Xd is extremely rare and is produced using nitrogen technology.

PE-Ha cross-linked polyethylene pipes are best suited for underfloor heating.

There are several types of cross-linked polyethylene pipes, they differ in the manufacturing method

Advantages and disadvantages

Pipes made of cross-linked polyethylene for heated floors have a number of advantages:

- Elasticity. This allows you to use the most optimal level of bending when laying, without the risk of subsequent cracking and fractures. Rehau products are considered to be especially high quality in this regard.

- Environmentally friendly. Cross-linked polyethylene contains no harmful components that would be released during heating. This guarantees safety in laying heated floors inside residential premises.

- High combustion temperature. The material begins to melt only after reaching a temperature of +400 degrees. As a result of the breakdown of the substance, water and carbon dioxide are formed, which are completely non-toxic.

- Excellent performance characteristics. The system, made of cross-linked polyethylene, is not afraid of rotting, corrosion and chemical influences. All this is the key to long-term and flawless operation of the water heated floor.

- Frost resistance. In the event of a significant drop in temperature, polyethylene products are not deformed.

- Sound-absorbing abilities. Thanks to this, there is no noise from the coolant circulating inside the circuit.

As for the weaknesses of polyethylene, they usually indicate the need for competent installation work. For example, it is recommended to securely fix turning areas, because this material does not hold the curved configuration given to it very well. In addition, the resistance of polyethylene products to direct sunlight is not very good.

Laying the contour must be done as carefully as possible, avoiding any damage to the protective layer

Cross-linked polyethylene or metal-plastic

Cross-linked polyethylene pipes and metal-plastic pipes are the main competitors when it comes to installing plumbing, heating systems or heated floors. They have a lot in common. Both types of pipes are quite flexible, durable, resistant to corrosion and relatively easy to install - you certainly don’t have to weld anything. True, it is still easier to install metal-plastic pipes than PEX pipes, with which you need to be extremely careful

Metal-plastic pipes have a slightly higher thermal conductivity coefficient (0.45 versus 0.38), but they will not survive freezing inside the coolant. PEX pipes, after the water in the system has melted, can be used as before. Moreover, some types of PEX pipes easily regain their shape. Resistance to high temperatures and pressure is high for both types of pipes: metal-plastic can withstand pressure up to 25 atm at a temperature of 250C, can be operated at coolant temperatures up to +950C with a short-term increase to +1200C, however, the maximum pressure is 10 atm. Thus, the performance characteristics are quite comparable with the similar parameters of cross-linked polyethylene pipes, which we cited above.

The choice depends mainly on the operating characteristics of the water supply system and the budget.

The range of prices among pipes, even within the same group, is significant, but PEX pipes are often cheaper than metal-plastic pipes. Date: September 25, 2021