The passage of a heating main with hot water near the place of residence is the prerogative of urban residents of apartment buildings; in country cottage villages, rural areas and dachas, the presence of a heating main laid nearby is very rare. An autonomous heating system helps solve the problem of heating a home in the cold season, which homeowners install in their home with the help of specialists from numerous companies or use the services of private craftsmen - doing the work yourself is problematic due to its high complexity and the need to use special plumbing tools.

Typically, individual houses are heated with heated water; due to its high heat capacity, it is the main type of coolant in heating systems; if it is necessary to take measures to protect against freezing of pipes, special non-freezing liquids (ethylene glycol, propylene glycol) are used in the system. Heating of liquid coolants is carried out using heating boilers operating on various types of fuel. The main task of the owner when choosing a heating method is to select the optimal type of fuel and boiler from the point of view of ease of use, minimizing costs during installation and operation, reliability and durability of the system.

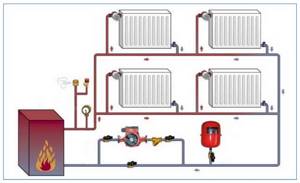

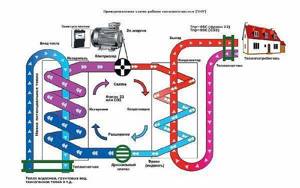

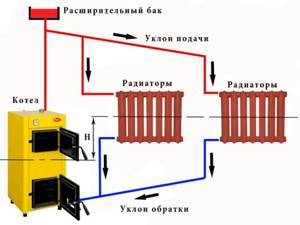

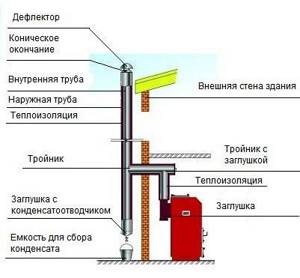

Rice. 1 Autonomous heating system and example of boiler connection

It may be useful to read about Connecting the boiler to the heating system

Pros and cons of autonomous heating

Autonomous heating primarily means independence from various factors, natural conditions and organizations that are, to one degree or another, associated with the sale of heating services or heating materials in a given area. The advantages of individual heating are:

- Selecting heating equipment and fuel type that is suitable for your financial capabilities and ease of use.

- Possibility to set the start and end of the heating season at your discretion.

- Adjusting a comfortable temperature not only throughout the house, but also in individual rooms.

- When designing, the advantage is that it is possible to place heating radiators at your discretion, remove or install one or more than one section on them to optimize heat transfer. You can lay heated floors, choose the boiler power and the parameters of the entire heating system within a wide range, regardless of the characteristics of the external heating main, the official connection to which is subject to some restrictions.

- If you are away from the house for a long time, you can completely turn off the heating or set it to operate in economy mode.

- The use of double-circuit systems in an individual home allows not only to heat buildings, but also to heat cold water to a high temperature for use in everyday life and for personal hygiene purposes.

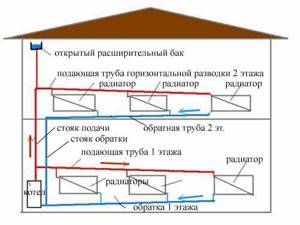

Rice. 2 Autonomous heating system in a private house - a variant of the heating and hot water supply scheme for DHW

- The use of solid or liquid fuels, which are stored in certain quantities, makes the heating system completely independent of external communications - gas pipelines, heating mains, and allows you to heat the house without being tied to emergency situations on engineering routes outside it.

Despite its many advantages, autonomous heating has quite significant disadvantages, the main ones being:

- Operation, maintenance and monitoring of an autonomous heating system takes up a lot of free time and requires some physical effort when using solid fuels.

- The main disadvantage of individual heating is the high cost of purchasing and installing equipment: a boiler, heat exchange radiators, manifold junctions and piping systems for underfloor heating, circulation electric pumps, plumbing fittings (air vents, check valves, shut-off valves and ball valves), automatic control.

- After installing the system, fuel costs also take up a significant part of the budget; many homeowners cannot afford to pay for the energy consumption of an electric boiler.

- During installation, additional costs will result in changing the configuration of walls, partitions and floors for laying pipelines, and installing screeds for heated floors.

- When using natural gas from the central pipeline as fuel, permission from the relevant services is required, and obtaining it is a long-term, complex and tedious procedure that requires the investment of significant sums of money.

- Financial resources will also be needed to ensure contractual obligations with organizations involved in the maintenance and repair of installed equipment and service center specialists.

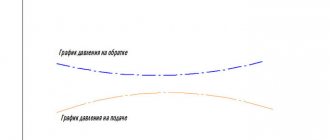

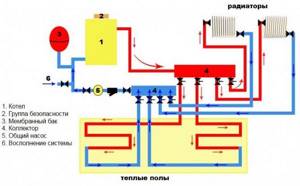

Rice. 3 Operating principle of a closed heating system

Types of heating in a private house

Heating a country house is done in several ways:

- Traditionally, a stove is used, when a solid fuel stove heated with wood, coal, peat and other combustible materials is used as a heat source. Also today, dried animal waste products (dung) are used, which in the steppe regions are the main source of heating.

Stoves can be of various designs depending on the traditions of different peoples.

Thus, in Europe, open hearths in the form of fireplaces have become widespread. They are heated with wood, and heat is distributed throughout the structure by convection. At the same time, in order to save money, not all rooms are often heated, but only those that are absolutely necessary to be heated. In the southern regions of Europe, special heating systems were often not made at all. The source of heat during the cold season was the kitchen stove, which was used for cooking; living rooms were located on the upper floors.

Heating devices appeared later, when heat began to be distributed evenly throughout the house using pipework. The initial reason for this was smoke from combustion products, often with tragic consequences. Therefore, the idea arose to separate the heat source from the living space, and to arrange a special channel for the smoke to escape - a chimney.

- Air heating is produced from a source that heats the air on its own surface or in specially equipped channels. Distribution of hot air occurs by natural convection. The fence is made in the lower part, from the floor, and the heated one rises up in accordance with the laws of physics. An example of this heating method is the Buleryan stove, which has become popular due to its economy and efficiency. It should be noted that the efficiency of such installations reaches 90%, which is inaccessible to many other devices. Air heating furnaces are most often used for heating technical premises, such as greenhouses. In some cases, they are installed as a backup fuel unit in a private home.

Pipe lines can also be used to distribute heat throughout a branched residential building. But the requirement for a large pipe diameter of such radiators makes them inconvenient to use.

- The times of massive combustion of petroleum products to produce energy are gradually becoming a thing of the past. And the first in a series of replacement methods were electrical appliances for a private home. The clear practical advantage of clean energy is not yet widespread, which can be explained by its high cost compared to gas systems. The main ways to use electricity to produce heat are:

- Central electric boilers that heat the coolant, which circulates through the system pipeline, heating the building with batteries.

- Electric convectors that generate heat with electric heaters directly at the point of consumption. In this case, it is possible to regulate the degree of heating. Such devices use forced air circulation, which allows the temperature to be reduced, preventing oxygen from burning through. The use of electric convectors requires significantly lower costs compared to a central boiler, but operating costs are approximately the same.

- Heating with infrared emitters is carried out by placing a special film on the ceiling. The waves it produces in a narrow range heat not the air, but the objects in the room. The device consumes a small amount of electricity and is an economical form of heating. The thermostats used only optimize the operation of the system and help reduce costs. At the same time, the equipment of an infrared heating system is quite expensive, and installation will require the participation of a specialist. The emitters are also used to install heated floors, with the film located under the finishing coating.

- Heating using a heat pump is not yet widely used. The main reason is the high complexity of installation and the significant cost of the device. The principle of operation is the same as that of a refrigerator, only heat, not cold, is taken away. During operation, heating costs are minimal, but significant cost becomes a decisive factor in failure.

- Induction boilers heat water very quickly and efficiently. However, calling the device a boiler is a stretch. The water in it is heated by a metal filler placed in the pipe when a high-frequency current passes through a coil wound on top of it. The control circuit uses an inverter, which regulates the degree of heating. Such a device must be used only if there is forced circulation of the heating system. Therefore, its control provides for blocking switching on when the circulation pump is not working. An attractive fact is that such a heating device cannot be the object of attention of regulatory organizations.

- A water heating system involves heat exchange through batteries through which water moves. Traditionally, it was water that was used, hence the name. Currently, it has been replaced by various liquids that do not freeze in certain temperature ranges (antifreeze, antifreeze). This is especially true when installing a heating system in private houses that are visited periodically. In this case, a variety of types of thermal devices are used.

The types of heating used in a private home are very diverse, but it should be noted that the most cost-effective is the use of gas boilers with water circulation systems.

If the area is not gasified, solid fuel stoves remain the main type of thermal energy generation.

Autonomous heating system - operating principle and main components

Any autonomous heating system includes the following main components:

Heat generator. It is a device that converts electrical or energy from burning fuel into heat, while the heat generator simultaneously transfers thermal energy to the coolant. Two main forms of the environment are used as a thermal carrier - air masses and liquid. Most often, purified distilled water is used in heating systems, which has the highest heat capacity coefficient, that is, the ability to transfer and accumulate energy; all other liquids, including non-freezing antifreeze, are significantly inferior to water in this indicator.

To convert fuel into thermal energy and transfer it to the carrier, the process of combustion occurs in heating boilers; if electricity is used, the heating of the coolant medium is carried out by heating the material with high electrical resistance to alternating current and its mutual heat exchange with the working fluid.

Heat conduction line. The coolant heated in the boiler is supplied to the heat exchange devices through pipes. Previously, steel pipelines were widely used (less often copper due to high cost), with the development of the chemical industry, steel is gradually being replaced by pipes made of polymers: PPR polypropylene, cross-linked polyethylene and PEX metal plastic.

Polymer pipes, due to their flexibility and elasticity, made it possible to install multi-circuit heated floors with water heating in buildings, which was impossible to do with metal pipelines.

Heat exchange devices. The coolant from the boiler flows through pipes into heat exchange devices, which in most cases are radiators; the liquid passes through them and transfers heat to the air due to the large area of the heat exchanger body. To increase or decrease thermal output, it is possible to change the battery configuration by adding or removing individual sections; the radiators are made of steel or aluminum, which have good heat output (high thermal conductivity).

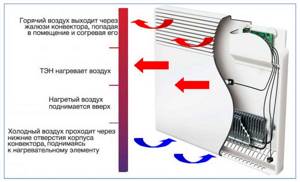

Rice. 4 Air convector - operating principle

Types of liquid coolant systems

As practice shows, most often a system with a liquid coolant is chosen to install autonomous heating, so let’s talk about its varieties. Such a system is implemented in the form of one of two possible schemes.

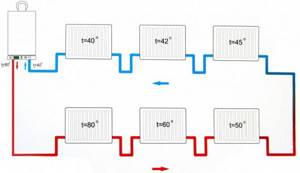

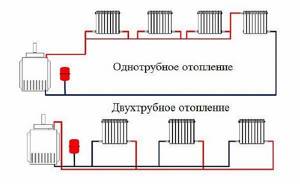

The simplest scheme is one-pipe

It is a ring-shaped closed circuit, inside which heating radiators are installed in series. The coolant flows into the first of them, then into the next and so on until it returns to the boiler. This is an extremely simple scheme, however, it is far from the most effective.

The main disadvantage of a single-pipe heating system is that the coolant cools down at the “approaches” to the radiators farthest from the boiler.

The single-pipe wiring diagram assumes a sequential arrangement of batteries. The system is very simple, but has limitations in application (+)

The liquid leaves the boiler heat exchanger at a temperature of about 75°C. It enters the first radiator the same way, in the second it is a little colder, and so on. If the pipeline is short and there are few radiators, then this is not a problem.

But if there are a lot of batteries, the latter will contain coolant heated to 45-50°C. Which is absolutely not enough for normal heating of the room

There may be two ways to correct the situation. The first is to increase the temperature of the coolant or add sections to the last radiators in the chain to increase their heat transfer. Both options will require additional cash investments, but do not guarantee results.

Image gallery

Photo from

Movement of coolant through one pipe

Length restrictions

Lack of control valves

Diagonal trunk connection

Another way to deal with the problem is to install a circulation pump. This will indeed increase the efficiency of a single-pipe system, but will also make it energy dependent and more expensive to operate.

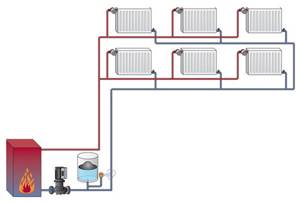

Improved scheme - two-pipe

The main difference from the first scheme is that the coolant is supplied to each of the radiators almost simultaneously. To supply it to the device, a supply pipe is used; a pipe called a return pipe is used for collection and discharge.

The coolant can be supplied to the batteries via a collector or tee circuit. In the first case, each of the devices is supplied with its own supply and return. Pipes are laid from the collector in the form of “beams”, hence the second name “beam”.

In the tee variety, the devices are connected in series to the supply and return using; assembly is carried out using connectors with three pipes - tees.

The two-pipe heating system arrangement assumes that a coolant supply pipeline and a discharge pipe, return (+) will be laid to each battery.

The collector involves installing shut-off valves on each outlet to the battery, which makes it possible to turn it off if necessary. The operation of a radiant heating circuit is based on forced circulation of liquid, because there are too many hydraulic obstacles in numerous rings for the natural movement of the coolant.

Image gallery

Photo from

Example of two-pipe heating

Tee two-pipe version

Radiant type of heating

Laying pipelines in a screed

Tee varieties can work both due to natural gravity and due to the inclusion of a circulation pump in the system. It pumps coolant, so when installing heating rings there is no need to maintain a slope, and the supply pipe must be installed below the heating devices.

The main advantage of the two-pipe scheme is to ensure uniform heating of all batteries in the building, no matter how many there are. But at the same time, its installation will require much more pipes and other elements, and accordingly, it will cost more. This is the main disadvantage of a two-pipe system.

Gravity circulation system

The coolant inside the heating circuit must move. This can occur through natural circulation. It arises due to the difference in densities that exists between the cold and heated coolant.

The heated liquid has a lower density, so it begins to spontaneously rise from the boiler along the riser, from where it is sent to the outlet pipelines and then to the radiators. As the coolant cools, its density increases, making it heavier.

The efficiency of a system with natural circulation of coolant fluid depends on the temperature difference, the height of the coolant rise and the correctly chosen angle of laying the pipeline (+)

For this reason, it falls lower and is collected in the return pipeline, through which it is supplied to the boiler. Thus, while the unit is operating, gravity-type coolant circulation will be realized. However, its speed is relatively low and can vary.

Most of all it depends on two factors:

- Location of system elements . Radiators should be located significantly higher than the boiler or raised to the ceiling, or even better in the attic, the main riser from which outlets will go to the batteries.

- Temperature differences between cooled and heated coolant . The larger it is, the higher the speed of fluid movement. For this reason, the main riser can be insulated with a special material to avoid heat loss, while the return pipe, on the contrary, is not covered with anything.

The advantages of a heating system for a private house with natural circulation include its low cost and simplicity in design, arrangement and maintenance. During operation, it is absolutely silent, there is no vibration.

There are quite a few disadvantages to the natural circulation scheme. It starts up slowly, which is explained by the low rate of movement of the coolant with a small temperature difference.

A well-designed system with natural circulation of liquid coolant can be quite complex and cover not only one, but also more floors (+)

In addition, for normal fluid circulation in the circuit, a pipeline assembled from relatively large diameter pipes is required. Such systems are limited in size due to the low natural pressure in the line. The horizontal length of such a structure cannot exceed 30 m.

Image gallery

Photo from

Gravity heating circuit

Large diameter pipelines

Acceleration section after the boiler

Minimum control and shut-off valves

Forced circulation circuit

A circulation pump is included in the system, it encourages the coolant to move at a certain speed. The pump is installed anywhere in the heating line.

But to install it on the supply side, you need to buy a pump only from trusted manufacturers, because it will have to work in unfavorable conditions, although all circulation models currently produced are designed for such operation.

The pump power is selected depending on the length of the pipeline and can vary. Thanks to forced circulation, the circuit can have different lengths, up to a very long one. The rate of movement of the coolant fluid does not depend on the temperature difference, which makes it possible to implement a variety of engineering schemes.

In addition, it becomes possible to use small-diameter pipes, which has a beneficial effect on the appearance of such a heating system.

The inclusion of a circulation pump in the circuit makes it possible to implement more complex engineering solutions and makes the system more efficient (+)

Among the disadvantages of heating with pump circulation, it is worth noting its energy dependence. This means that if there is no power supply, the heating will not work. For places where power outages are common, this is a very serious disadvantage.

In addition, installing a pump will require additional costs for its purchase, installation and subsequent operation.

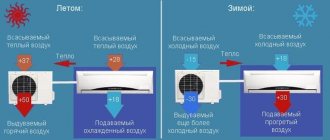

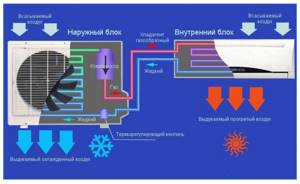

Autonomous heating system with air convectors

An autonomous air heating system usually involves the use of electric convectors, the built-in fan of which supplies air to the heating elements, after which it enters the room. Air conditioners operating in heating mode, and ordinary cheap electric heaters without fans with an open spiral, or oil heaters, where the heating element is immersed in the coolant, can heat the air. The latest technology is the use of energy-saving air-to-air heat pumps for heating; the thermal energy obtained as a result of their operation is transferred to the air masses and distributed throughout the entire area of the room due to built-in fans.

Heating rooms with heated air is not a very popular method among consumers and has the following features:

- All air heating options allow you to heat a room in a short time, unlike water heating, which requires significant time intervals to start supplying heat.

- Electric convectors with an open spiral burn oxygen - this worsens indoor air quality and can cause headaches.

- If one convector is used to heat several rooms, you will have to install a bulky air duct system and suspend it from the ceiling.

Rice. 5 Heating with air conditioners

- In addition to heating, a high-tech heat generator (air conditioner) is capable of performing the functions of humidifying, filtering or cooling air during the warm season.

- The heating installation and ventilation ducts are not at risk of defrosting during the cold season, as well as leakage of the coolant in the system, which is air.

- Air heating is easy to implement in any room of large or small area; in the simplest case, it is enough to connect the convector to an outlet to receive heat.

In addition to small heat generators running on electricity, stationary large heat generators running on gas or liquid fuel are used for air heating; their main components are (Fig. 7):

- Gas burner placed in a large volume container (housing).

- Combustion chamber in which gas combustion occurs and its thermal energy is transferred to the air.

- A system of fans providing air exchange and supply of heated air into the air ducts.

- Air duct hoses that direct the flow to different rooms.

- Electronic automatic control and monitoring system with setting the operating mode and temperature parameters of the convector.

Rice. 6 Autonomous heating system with heat pumps

We heat a country house with natural gas

Natural gas is a leader among other types of fuel. With a modern, efficient boiler, a well-insulated house can be heated at minimal cost. Of course, there are cheaper sources of energy, but they are not autonomous: solid fuel must be constantly supplied, electricity can be turned off, and gas in cylinders periodically runs out.

Features of using gas boilers

When choosing a boiler, you need to proceed from the area of the house and hydraulic calculations. A wall-mounted convection boiler copes with heating a three-hundred-meter house. Condensing equipment can be installed. It is suitable for houses up to 400 m2. Such boilers use not only the energy of fuel, but also steam condensate. Their energy efficiency is much higher. If suddenly the equipment performance is not enough, you can use the “cascade connection” function.

Several years ago, the cost of a heating boiler was very high. But now that this equipment has become quite affordable, using natural gas to heat a home and organize hot water supply is more profitable than any other type of fuel

Hot water supply can be provided by an electric boiler, but if the heating of a private house is based on the use of natural gas, it is more economical to use it to heat water. To do this, you need to purchase either a double-circuit gas boiler or supplement the existing one with a tank. You can choose the volume based on your household needs. Boiler columns maintain a supply of water at the desired temperature. A flow-through gas boiler heats the water at the moment of supply. After opening the tap, cold water will come down first, and only then hot water will flow.

Diagram of the design of such a system

The diagram of a gas heating system for a private house includes a heat source from which the coolant first disperses through the collector through pipes to the radiators, and then, when cooled, returns to the boiler. The liquid is under pressure. The circulation in this case is forced. Additionally, air vents, shut-off valves, flow and temperature sensors, and thermal heads can be installed. Automation helps regulate the temperature.

The system can also be designed for natural circulation, in which case an expansion tank is included in the scheme at the highest point of the house. Here you can save on temperature sensors, air vents and expensive pumps.

Heating distribution can be radial or tee. The first is more expensive due to the larger pipeline footage, but it is more efficient and mobile, it is easier to repair during the heating season. The second is cheaper due to the smaller number of pipes, but it does not provide such wide opportunities for regulating the temperature in individual rooms as radial wiring.

The number of radiators in the system is determined based on thermal and hydraulic calculations. This is the most correct option from both a technical and economic point of view.

Natural gas heating equipment requires minimal maintenance, which, by the way, can be done on your own. The fuel burns without forming a solid residue. To avoid installing a chimney, you can purchase a boiler with a closed combustion system.

If by the end of the construction of the house there is no gas main, you can purchase a boiler using two types of fuel. After gasification, the transition to economical and efficient natural gas will not require significant material costs. At most, you will need to call a specialist from a service company.

Types of liquid autonomous heating systems

Heating systems for heating an individual home using water and non-freezing liquids (antifreeze) as a coolant differ in a number of ways, the main differences:

By type of fuel used . The most popular types of energy for heating coolants are electricity, gas, liquid flammable hydrocarbon mixtures (diesel fuel, fuel oil, oil, kerosene), a large number of solid combustible materials - firewood, coal, peat briquettes and pellets of various compositions. Electricity can be obtained either from energy companies or independently using solar panels, wind or hydraulic generators.

By type of thermal generators . In modern heating systems, heating boilers are used to transfer energy to the coolant, which have design features and differences between analogues for each type of fuel. With a lack of funds, many craftsmen assemble autonomous heating with their own hands, using self-assembled structures, mainly solid fuel, instead of factory boilers, a typical example is a metal stove in a living room with an expansion tank in the attic and a steel piping system with radiators.

Gas heating of a country house

If at the dacha it is possible to connect to the main gas pipe, then the question of how to choose heating for a dacha house disappears by itself: the boiler is able to heat a country house in a short time, and the cost of the energy spent will not be too burdensome for the owners.

Small, low-power wall-mounted models are suitable for dachas; they are more than enough to heat a small house. In a gas boiler, the coolant, just like in an electric boiler, is water or antifreeze. This heating scheme assumes the presence of an installed pipeline heating system in the house.

When heating a country house, a gas boiler can operate completely autonomously (without consuming electricity). In this case, the water in the pipeline does not circulate forcibly due to the operation of the pump, but independently according to the principle of convection. That is, hot water, expanding when heated, pushes cold water into the heating zone, and so on without interruption. However, to install a non-volatile boiler, it is necessary to take into account the slope of the pipes and the height of the heat generator relative to the radiators and heating pipes.

Despite the fact that a gas boiler can be installed with your own hands, it is unlikely that you can do it without a service specialist; his responsibilities include connecting the boiler to the gas main and starting the heating unit for the first time.

If you are determined to take advantage of the benefits of a gas boiler, but do not have the opportunity to connect to pipeline gas, then you will have to install a gas tank. These welded cylindrical or spherical tanks are made of steel and are installed underground. They store liquefied gas under high pressure. The container is replenished as needed. It is worth noting that such a gas supply scheme for a dacha will entail significant costs not only for the installation of the tank itself, but also for its regular replenishment.

Regardless of whether it is a gas boiler or an electric one, it is necessary to provide for the possibility of water freezing in the pipelines and, as a result, their destruction. Using antifreeze as a coolant or using pipes with a heating cable under insulating insulation will help to avoid such an accident. In addition, the boiler protection unit will help to protect the heating system. Since its operation requires electricity, emergency power supply to the boiler from a diesel generator should be provided.

Boilers for water autonomous heating - types and features

Heating boilers are the most used equipment in the private sector, with their help they not only heat houses, but also heat cold water for household needs and personal use for hygiene purposes, using double-circuit modifications. Factory-made boilers are distinguished by their reliability and long service life, relatively affordable price, efficiency and comfortable operation; when installing simple collectorless heating systems with radiators only, it is possible to install all the heating equipment yourself. When choosing a boiler, they are primarily based on the cost and availability of fuel; their main options are discussed below.

Autonomous heating with gas boilers

Today, gas autonomous heating is the undisputed leader in prevalence due to the low cost of gas and a developed network of gas pipelines.

Gas heating has the following features:

- Lowest fuel costs compared to other types of fuel boilers.

- The cost of a typical boiler is higher than that of similar equipment of other types; its average price is about 42,000 rubles.

- The equipment requires regular maintenance by service specialists; before its installation, numerous approvals must be made with gas services.

- The gas is explosive, therefore, during installation and operation, special attention should be paid to the reliability and tightness of connections.

- When gas burns, oxygen is consumed, so good ventilation must be provided where the boiler is located. The product of combustion is soot, which settles on the inner walls of the chimney - this requires the use of measures to periodically clean it.

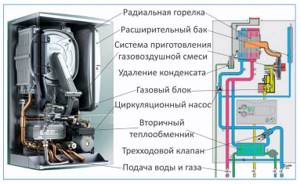

Rice. 10 Gas boiler - main components

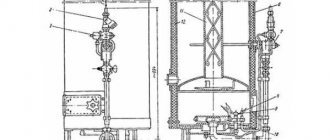

Autonomous solid fuel heating system

Solid fuel boilers are classics and rank first in popularity in areas where there is no centralized gas supply; solid fuel heating has the following features:

- The cost of boilers is the lowest among all analogs; the average price of a standard model is about 17,500 rubles.

- Fuel is available in all areas of the country; in coal mining areas, coal is naturally used more often than other varieties; in the middle zone, peat briquettes, eurobriquettes, firewood and wood waste, and pellets are popular.

- Storage of solid fuel requires a certain place; its storage and use takes up a lot of free time and requires constant cleaning in rooms with boiler equipment.

- The products of combustion are soot, which, when released into the air, settles on the surface of the earth, polluting the environment and atmosphere.

- Due to the large amount of soot in pipelines and chimneys, they require regular cleaning of sediment; if this procedure is not performed or there are delays, there is a high probability of soot ignition, leading to fires.

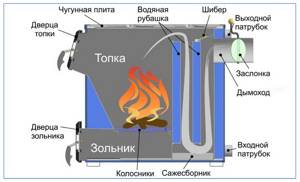

Rice. 11 Solid fuel thermal generator - operating principle

Autonomous liquid fuel heating system

Liquid fuel heat generators are not as common in everyday life as gas and solid fuel equipment; unlike domestic consumers, this type of heating is highly popular among residents of Western European countries. Features of heating buildings using liquid fuel boilers are the following factors:

- Diesel fuel, kerosene, gasoline, and waste vegetable oil can be used as fuel.

- The average cost of a domestically produced low-power liquid fuel boiler is about 30,000 rubles; the price of imported models can exceed this amount by 10 times.

- All boilers are characterized by high operating efficiency (efficiency), which averages 92%; 1 liter of fuel per hour is consumed to produce 10 kW/h of thermal energy.

- The power of manufactured products lies in a wide range and is designed for heating from one-story small residential buildings to large production workshops.

- Almost all boilers operating on liquid fuel can operate on natural gas.

- Thanks to the built-in automation system, human presence is not required when operating the equipment.

- When a gas connection is not used, installation of the boiler does not require permits from the relevant organizations.

- The equipment is characterized by high autonomy; if electricity is required for operation, it is obtained by burning the same fuel in an electric generator.

- Fuel has a high cost, so operating the boiler will cost more than other types.

- To store fuel reserves, it will be necessary to erect a separate outbuilding or shed; under it, containers with fuel should be placed in the ground to protect from the sun, which reduces its characteristics.

- To install the unit in a house, you will need a separate room equipped with powerful exhaust ventilation, since the burner makes noise during operation, the room will need to be soundproofed.

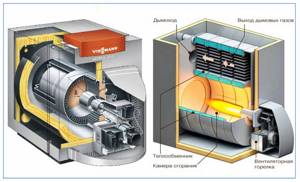

Rice. 12 Liquid fuel boiler - main components

Autonomous heating system using electricity

Electricity is the simplest and most accessible type of energy, which can be obtained both from state power lines and independently, using the energy of the sun, wind, moving water; in electric generators, electricity is obtained by burning liquid fuel. Electric boilers are quite different from similar units in the following properties:

- The average cost of a typical household boiler is about 35,000 rubles.

- The equipment operates reliably and silently.

- During operation, no harmful substances are released into the atmosphere; installation of air ducts and chimneys is not required, or the installation of special exhaust systems to renew the air in the room.

- The service life of the main tubular electric heating elements (TEHs) does not exceed 15-20 years.

- Operation does not require human intervention; electronic programming of the system is possible, in which the boiler will operate independently for many months.

- The equipment is sensitive to surges and sudden power outages, in this case nothing will happen to the heating elements (resistive elements are not sensitive to energy changes), but the automation may fail.

- In areas with unstable power supply and frequent accidents, the use of an electric boiler is problematic - if there is a long absence of electricity and the boiler is turned off, the pipeline with the coolant may freeze.

- Installation and assembly of the electric boiler does not require approval from the relevant services.

- High electricity tariffs prevent the widespread use of such an electric heating system in everyday life.

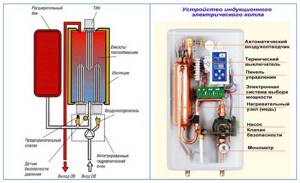

Rice. 13 Electric boiler - device

You might be interested: Do-it-yourself heating in a private house from polypropylene pipes

Autonomous heating using diesel fuel

Autonomous heating with diesel fuel is not one of the most common heat supply systems due to the high cost and uneconomical nature of the diesel fuel used in it, although the boiler itself and auxiliary equipment are relatively inexpensive and are not difficult to install.

Positive sides

- new boiler models are equipped with heated burners, which allows you to use fuel economically.

- excellent thermal insulation of the boiler shell.

- equipment designed for autonomous heating of a private house using diesel fuel has a safety control system.

- the boiler does not require gas consumption.

- in the future, the equipment can be re-qualified for heating using natural gas at any time.

Negative sides

- Diesel fuel is much more expensive than gas and electricity.

- Diesel fuel equipment requires a separate room.

- Any control system with an automated operating principle requires electricity.

- the price of the heating system itself differs from the cost of other equipment to a greater extent. Installation work, a vessel for storing fuel and equipment for refueling routes require considerable expenses.

- The system requires necessary maintenance and must be constantly monitored by specialists and undergo timely cleaning.

- The fuel used must be of very good quality.

Usage example

To roughly estimate the cost of such heating in real conditions, you can imagine a house with an area of 150 m². Let's say it has 6 rooms and needs to be heated by a diesel fuel heating system. Approximate costs for installation work and the purchase of the equipment itself will cost about 200 thousand rubles. To get a complete picture, you can calculate the approximate cost of monthly heating. In winter, fuel consumption will increase even more, and the possibility of heating water will also most likely be used. The operation of such a system will cost approximately 20 thousand rubles per month.

Criteria for choosing a boiler for autonomous heating of a private house

When choosing the type of boiler for heating, there are no alternatives only if gas is supplied to the house; it is the cheapest type of fuel and, in comparison with other sources (electricity is not considered), has a number of operational advantages - it does not require space for storing reserves, highlight There are fewer combustion products released into the environment and does not pollute the chimney system as intensively.

The main parameters that people pay attention to when choosing a boiler are:

- Unit power: directly related to the area of heated premises and temperature conditions, which are usually chosen based on building codes and GOSTs.

- Number of circuits: if the house does not have hot water supply, it is more practical to choose a dual-circuit model that can heat water.

- Location: usually the unit is installed downstairs in the basement on the floor; there are also hanging options for small houses.

- Material of manufacture of the unit and heat exchanger: cast iron, stainless steel, copper.

- Type of combustion chamber according to the method of supplying air to the firebox: open or closed.

- Availability of automatic control and monitoring systems, possibility of programming operating modes.

- The ability of the boiler to work with alternative fuels: relevant for liquid fuel modifications.

Boiler operating rules

If the boiler is an open type, then it must be installed on the floor, which is covered with a fireproof layer. If the room in which the boiler room is located has a small area, then it is necessary to provide an additional ventilation system. The chimney must provide the necessary draft, which is needed for normal combustion, so you need to take care of its arrangement in advance. By installing a stabilizer, you don’t have to worry about the traction not being at the proper level.

Boiler chimney diagram

Selection of a boiler for autonomous heating by power

The passport data for the boiler must indicate its rated power; sometimes the manufacturer gives the area of the premises in square meters that a given boiler can heat. For average calculations, we take the consumption of 1 kW of thermal power of the unit to heat 10 square meters of living space with a ceiling height of 2.5 - 2.7 m. If the height is greater, a correction factor is introduced, for example, the power is multiplied by 1.23 at a distance from the floor to the ceiling 3.2 m.

Also, the calculations take into account the climatic zone in which the house is located; it is included in the formulas in the form of a correction factor and ranges from 0.7 for the southern regions to 2 when housing is located in the northern regions. If a double-circuit boiler is used to heat water, its design power is increased by 20 - 25%.

To determine the power of a heat generator, SNiP 2.04.07-86 is sometimes used, according to which for low-rise buildings, if the average external temperature is -25 ° C, heat consumption is calculated according to the standard 173 - 177 W / m2, and in high-rise apartments the standard is taken to be 97 - 101 W/m2.

To summarize, it should be noted that for approximate accelerated calculations taking into account various factors (hot water supply, high ceilings, cold climate), a boiler is usually selected with an average power, which should be about 1.5 kW per 10 m2 of room.

Rice. 16 Example of calculating thermal power

Electric heating

This type works on electric boilers. Its advantages:

- low noise level during operation;

- affordable price;

- reliability of design;

- easy installation.

The service life of electric boilers is 15 years . Heating a house with this system makes it possible to program the air temperature. This can be done using a temperature sensor, which is best installed in the coldest room.

Minuses:

- high cost of electricity;

- the need for constant access to it.

Stages of installing a heating system with your own hands

Installing a simple heating system in a house with your own hands without manifold wiring and laying heated floors is a task that many homeowners can do if they have simple construction and plumbing tools. For efficient and high-quality work, you will also need knowledge of the boiler installation diagram (instructions to help), technologies for installing various types of pipelines, special skills in soldering or welding pipes if a polypropylene or steel pipeline is selected. Do-it-yourself installation of an autonomous heating system in a private house or apartment from A to Z is carried out in stages in the following order:

- They independently draw up or order a heating scheme from an architectural organization, taking into account the design features of their home, and the construction of a well for connection to the gas pipeline.

- Determine the type of fuel and boiler that will be used to heat the premises, its configuration (double-circuit or single-circuit).

- Select the material of the pipes if you plan to hide them under the floor when connecting them to heating radiators; purchase products made from cross-linked polyethylene PEX of a suitable diameter. Their undeniable advantage is flexibility, the ability to interconnect and connect to heating equipment using compression fittings that do not require special crimping or soldering plumbing tools.

If the pipeline is laid over a surface, you can use polypropylene, steel or copper pipeline, the elements of which are connected by soldering or welding.

- The type of heat exchange devices is selected, calculating the number of radiators and the required battery power in accordance with the area of the heated premises and the optimal temperature in the premises; the number of sections is calculated manually or using calculators.

- They decide on the connection diagram for their batteries; it can be one-pipe or two-pipe; the best results are shown by the accompanying two-pipe wiring, which ensures the same heating temperature for all radiators connected to the line.

Rice. 17 Gas boiler for autonomous heating - installation option

- They begin installing the system by installing the boiler on the floor in the basement and hanging it on the wall, after which through holes are drilled in the walls and a pipeline is installed; if the heating pipes are located in the floor, grooves are cut in the screed into which the pipe line is laid.

Grooves are also made in walls if the pipeline is running along the surface and they want to hide it to improve the aesthetic appearance.

- Radiators are hung on the walls, to reduce heat losses, a foil film is placed behind them to reflect infrared radiation, and a heating pipeline is connected to them.

- The system is filled with water and checked for leaks; for this, the liquid is supplied under pressure 1.5 to 2 times higher than the working pressure (pressure testing) and the system is left in this position for 30 minutes to 24 hours.

- Turn on the boiler at a low temperature and check the heating of all radiators, using the Mayevsky taps built into the batteries to remove air pockets that interfere with circulation and heating. After de-airing the entire system, turn on the boiler at full power and sequentially check the functioning of the system under different operating modes, changing the flow rate on the circulation electric pump.

- The final stage is balancing the system in order to achieve the same heating temperature for all radiators; for this, thermostats are usually built into them before installation and the user can only check their correct operation with a thermometer.

Fig. 18 Solid fuel boiler with a capacity of 20 kW in the basement

Heating schemes - one-pipe and two-pipe systems, which is better, and what determines the choice of scheme

Heating a private house can be done with your own hands using various schemes. There are two main methods of installation - one-pipe and two-pipe schemes.

The single-pipe heating system is very popular among individual developers for the following reasons:

- The relatively affordable cost of the device and its simplicity, allowing you to do everything yourself. It is enough to have the skills of an average welder.

- Hydraulic stability, in which the heat transfer of the wiring does not change when a separate heating element is turned off.

- Economical use of the main material - pipes.

- The system is characterized by low inertia and rapid heating of the circuit, which is explained by the reduced amount of coolant with this scheme.

- Aesthetic external design, especially when the main pipe is installed in the wall.

- The use of modern shut-off and control equipment (automatic and manual temperature regulators) allows for precise adjustment of the system and ensures its stability.

- Simplicity of design, which determines its reliability.

- Easy installation, maintenance and operation.

The use of automation tools allows you to include a single-pipe system in the Smart Home control scheme complex, which regulates its operation depending on weather conditions, time of day, season and other factors.

The main complaints about such a connection scheme for a private home are the uneven heating of individual elements - the greater the distance from the boiler, the slower the batteries heat up, since the coolant cools as it moves along the circuit.

This effect is partially offset by the use of a circular pump. You can also increase the number of sections in remote batteries, which will even out the heat transfer.

Such measures can significantly reduce the influence of negative factors. As a result, water heating made according to this scheme is considered the best for private houses with an area of up to 150 m3.

In a two-pipe heating system, all radiators are filled simultaneously. This ensures uniform heating of the entire pipeline.

Video – One-pipe / two-pipe circuit

Single-pipe/two-pipe heating system

At the same time, it becomes possible to adjust the amount of coolant passing through any of the system’s collectors.

Such a scheme, done correctly with your own hands, has a number of certain advantages:

- Possibility of automatic temperature control in each room.

- Each circuit operates independently; a failure in one of them does not affect the functioning of the others.

However, there are certain disadvantages:

- increased design complexity;

- high material consumption of wiring;

- increased complexity of execution.

The stability of operation of all systems depends on the choice of heating system scheme for a country house. So, for buildings with permanent residence, it is permissible to use a single-pipe connection scheme.

It is better to use a two-pipe system in houses with periodic visits, when it is possible to warm up the home with reduced fuel consumption.

The choice of connection option depends on the wishes of the developer and is entirely within his competence.

Registration of permits for the installation of autonomous heating

To install an autonomous heating system in a country house, you will have to contact the rural or city administration at your place of residence, since the installation of such a system is a reconstruction or redevelopment of the premises, you will need the following documents:

- Application in the approved form, which is specified in Government Decree No. 266 dated April 25, 2005.

- Certificate of ownership with accompanying documents: state registration, agreements of donation or transfer of ownership of housing, notarized right of inheritance.

- With shared participation, confirmation of real estate ownership will be required from all owners and their consent to install the system (signature of all residents on the application).

- A photocopy of the technical passport of the premises.

- Confirmation by architectural authorities and organizations involved in the protection of monuments, the status of housing - whether it represents architectural, historical or cultural value.

- A project for installation or redevelopment, consisting of a plan for the placement of a gas pipeline and the installation of a boiler.

- When installing a powerful electric boiler (if the value exceeds 30 kW), you will need a copy of its passport with confirmation of the maximum power, and a power supply agreement.

- A home renovation project (moving or dismantling internal partitions, walls, door and window openings), if it occurs during the installation of equipment. It is compiled by the design organization; the documents contain basic information on the installed system and technical calculations. Design solutions are also coordinated with fire services, sanitary and epidemiological stations, and gas workers.

- Technical conditions for connecting the gas main (issued by gas distribution government organizations or private owners of fuel and communications), ventilation devices in the room with the boiler.

This package of documents is submitted to the interdepartmental commission responsible for the operation of the housing stock and located in the administration; you should expect a response in about 45 days.

After the connection and installation of networks by the relevant services, an acceptance certificate is drawn up, a copy of which is submitted to the real estate registration service.

Rice. 19 Installed liquid fuel boiler

Video on the topic

How to make autonomous heating in an apartment with your own hands:

The advantage of the owner of an autonomous heating system is that his hands are free: it is possible to supplement the conventional system with alternative heat generators, which will significantly reduce costs. These are solar collectors (vacuum ones are the most effective) and heat pumps that use heat from low-potential sources: water and soil with a temperature of +50 – + 100 C.