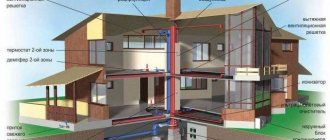

The main difference between the use of pile structures in the construction of frame buildings is the presence of an empty gap between the soil and the grillage. The use of this technique leads to significant heat loss during the cold season. Because of this, the level of comfort of residents is noticeably reduced, and various malfunctions may also arise that threaten the integrity of the entire structure of the building.

Expert opinion

Konstantin Alexandrovich

In order to increase the life of the house and make your stay in it more comfortable, you need to insulate the floor in the house on screw piles.

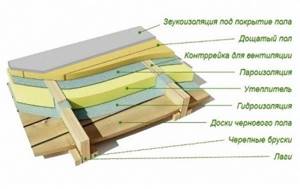

Layers of wooden floor of a frame house

The layer of wooden floors in a frame house, both on a reinforced concrete foundation and on a pile, consists of several layers:

- Flooring made of boards, particle boards and other materials. This flooring is called a subfloor.

- A layer of wind protection if the floors are mounted on a pile foundation, which creates a large gap between the subfloor and the ground.

- A layer of moisture-proofing material. Modern materials that combine wind and moisture protection materials can be used.

- Wooden logs. They create a base for a finished floor covering, as well as an additional insulating space with a height of 15 cm to 20 cm.

- Insulation. It is laid between the joists and completely fills the air space of the floor. Any modern material can be used: stone wool, polystyrene foam and even the old-fashioned expanded clay. Learn more about the properties and advantages of expanded clay insulation.

- Vapor barrier. It is mounted on logs, above the insulation and secured with the following layers of the floor.

- Finished floor surface. All of the listed layers along the logs are covered with boards, OSB, or even in 1 or 2 layers, depending on the project.

- Clean floor covering. Finishing material: laminate, parquet board, parquet and others.

layers of floors on joists

What materials will be needed

Insulation products on the construction market are presented in such a wide range that many consumers have difficulty choosing materials.

In fact, the most optimal options for insulation products are the following:

- Styrofoam

- Foam glass

- Expanded polystyrene

- Penoplex

- Polyurethane foam

Sheets of insulating material are glued to the surface of the base. The seams between them are rubbed and sealed using polyurethane foam. Then be sure to apply a layer of waterproofing material (for example, mastic or roofing felt).

Ruberoid insulation of the foundation

Design Features

Structures with pile-type foundations are most often installed on soils with high humidity (near water, in swampy areas) or on slopes. Such a dwelling has nothing under the floor: neither a basement nor a ground floor. In addition, drafts constantly blow under the floor and there is increased humidity. Because of this, a house built on screw piles necessarily requires thermal insulation. Then it will last longer and living in it will be more comfortable.

Arranging such a floor is quite complicated. It should be multi-layered. The design resembles a “pie” for roof insulation. It should be thought through at the stage of building a house.

The design of a heated floor should include:

- Load-bearing frame made of wood with a subfloor.

- Wind insulation layer. It should allow steam to pass through, but protect the insulation from weathering.

- A layer of insulating material.

- Steam and moisture insulating coating.

- The interior floor of a room, covered with boards and finishing materials.

Design Features

One of the conditions for reliable arrangement of a frame house is high-quality materials. If you use cheap products when insulating the floor or skip one of the layers, this will lead to very undesirable moments. There will be significant heat loss through the floor. As a result, the cost of heating the room will increase. High humidity and condensation will provoke the development of fungus, rotting and destruction of wooden boards and beams. As a result, the service life of the floor and the entire room will be reduced, and regular expenses for repairs will be required. Reliable insulation will allow you to avoid all these problems.

Before starting construction work, you should choose insulation.

Types of sewerage

Our ancestors did not think about solving the problem of water drainage. She passed the floor coverings and went into the ground. If you are interested in this option, then you need to build the bathhouse on a small hill so that water does not accumulate under the floor. This will speed up the process of wood rotting.

If you have built a bathhouse on your own plot, then you are unlikely to be interested in the above water drainage option. Sewage must be redirected to designated areas (cesspools or septic tanks). To achieve this, the subfloor design must be slightly modified. It is necessary to install a stainless steel trough under the joists, in which water will accumulate and then flow further through the pipes.

The installation instructions for such a sewer system do not have any difficult moments.

The only thing you should pay attention to is the sequence of installation of waste pipes if there is a toilet in the bathhouse. The pipe coming out of the trough must be in the general system after flushing the toilet

This is a civilized method of disposing of wastewater, and a bathhouse with a storage tank under the floor is warmer. The possibility of drafts is almost completely eliminated. In addition, it is possible to install insulating material on top of the trough.

Bathhouses on stilts located in summer cottages should be given a presentable appearance. It is unlikely that a design with a trough under the floor will seem appropriate. You can decorate the entire perimeter of the room with a variety of materials - from wood to brick. This finish is not only an aesthetic component, but also additional thermal insulation.

What insulation is better for the floor of a frame house?

Floor insulation in a frame house can vary depending on the purpose of a particular room. According to GOST (state standard), the following can be used as insulation:

- expanded polystyrene;

- Styrofoam;

- mineral wool;

- ecowool;

- penofol;

- penoplex;

- expanded clay and other types of insulation.

The thickness of the insulation for the floor of a frame house in central Russia is chosen to be 200 mm. For more northern regions - 300 mm.

To insulate the floor of a frame house, you must choose only high-quality insulation. Otherwise, you may end up with insufficient insulation, which will lead to unnecessary costs for heating the premises.

Insulation with polystyrene foam or expanded polystyrene is the best and simplest solution. It is actively used in budget construction. The only condition is the use of good waterproofing so that the foam does not disintegrate into individual elements. When temperature changes, the foam can still form cracks. This is its main drawback.

To prevent such unpleasant moments, you need to lay the sheets “under tension” so that the sheets are tightly clamped between the joists. Such work should be performed by knowledgeable specialists.

Laying foam plastic between floor joists “in tension”.

Mineral wool can be used with great success for insulation. It has high thermal protection, is not flammable, but is also resistant to moisture. Waterproofing in this case must also be of high quality. It is better to use mineral wool in the form of mats than in the form of a roll, because the mats are denser. Be sure to cover the gaps between the mats.

If you choose an insulation thickness of 150 mm, then it is advisable to lay a layer 100 mm thick and cover the cracks with another layer 50 mm thick.

Ecowool is an analogue of glass wool, but is more environmentally friendly, although many experts question this fact. Ecowool is sprayed using special equipment and forms a layer of seamless insulation. Ecowool retains heat better than mineral wool, but is more expensive.

Insulating the floor with penoplex, which is a type of polystyrene, but is more reliable in strength and has a higher degree of thermal protection, will cost much more.

Insulating a frame house with expanded clay is quite possible. Expanded clay is cheap, it is fire resistant, and is also environmentally friendly. It is quite possible to insulate a floor with expanded clay yourself, without resorting to the help of a construction team. True, expanded clay is inferior in thermal conductivity to the materials listed above.

When insulating a floor with expanded clay, it is imperative to use waterproofing, because expanded clay absorbs moisture well. A layer of expanded clay is laid on the waterproofing, a leveling screed is made on top of it, then another layer of waterproofing is laid.

In principle, absolutely any insulating material can be used to insulate the floor. In the simplest cases it can be sawdust. As a rule, the better the quality of the material, the higher its price. Each owner chooses which heat insulator to choose.

Load-bearing elements

It is acceptable to carry out the flooring in a frame house immediately after the foundation has been laid out and the framing has been arranged. Naturally, before starting work with the strapping, you should lay a layer of waterproofing, for example, roofing felt, penofol or polyethylene film.

After completing the activities with strapping and laying the last beam, the installation of logs begins in increments of 500 mm.

To use a heated concrete monolith, the structure should be strengthened using transverse jumpers with a pitch of 150 mm. Also, a board with a section of 30 by 30 mm is used as an amplifier for a clean base.

On the second floor, the floor is laid directly on beams with a cross-section of 500 mm.

Technology for floor insulation in a wooden house on screw piles

Domestic SNiPs exist exclusively for the calculation of pile foundations. There are no regulatory documents for insulating the basement of a building. Ventilation and insulation of these architectural elements is carried out in accordance with the requirements of SNiP dated 2003, number 31.01 for residential buildings (now replaced by SP 54.13330.2011).

The manufacturer of extruded polystyrene foam Penoplex has technical solutions for heated floors using joists. Taking into account the requirements given in these documents, the individual developer must ensure:

- laying insulation between the joists - sheets of expanded polystyrene or basalt wool rest on the subfloor, are waterproofed from below and covered with a vapor barrier from above;

- fence for piles - imitation of a plinth made of facing material on a frame;

- ventilation ducts - the area of each hole is from 0.05 m2 (most often the pipe is 100 mm), the total area is 1/400 of the perimeter of the basement walls;

- blind area around the perimeter - for drainage of storm and melt runoff.

The best option in this case is the Maxiwood composition or similar compositions:

- colorless transparent liquid without harmful secretions;

- has the density of water, allowing you to treat logs with a spray gun;

- increases moisture resistance by 20%, penetrates the wood structure by 1 cm, creating crystalline structures inside it.

It is better to treat joists, beams, and subfloor boards with waterproofing materials at the initial stage of construction of a home. This will eliminate the need to open the base at the finishing stage to install the heat insulator. The technology for heated floors on beams is as follows:

- sheathing arrangement - bars are attached to the bottom of the beams, joists from the inside along the load-bearing elements of the floor;

- installation of the sub-base - OSB, chipboard, multi-layer plywood or edged boards are laid between the beams on previously nailed bars (the lower part is impregnated with a penetrating mixture);

- waterproofing - waterproofing is laid on top of the base;

- thermal insulation - basalt wool or extruded polystyrene foam (PSB-S or XPS) is laid on top of the waterproofing in three to four layers in a checkerboard pattern;

- vapor barrier – the top of the insulation is protected by a vapor barrier.

The further scheme for insulating a house on screw piles may differ depending on the type of flooring included in the room design:

- multilayer plywood - for laying laminate, parquet, floorboards, piece or modular parquet, cork, carpet and linoleum;

- dry screed - for decorating with porcelain stoneware, linoleum, tiles, cork, PVC tiles and laminate;

- self-leveling screed - most often for underfloor heating systems.

Floor insulation scheme

For a building on screw piles, the following floor thermal insulation scheme along the joists is used:

Scheme of floor insulation along joists in a wooden house.

- cranial block - fixed with self-tapping screws, nails flush with the lower edge of the beam;

- subfloor - filling the space between the joists with edged boards, plywood, OSB, chipboard;

- waterproofing – roll of glassine, roofing felt, PVC film, special waterproofing membranes;

- insulation – XPS or PSB-S expanded polystyrene blocks, basalt wool;

- vapor barrier - a membrane or film that cuts off excessively humid air from the room into the heat-insulating layer;

- sound insulation - ready-made solutions from manufacturers ZIPS, Knauf or an additional layer of mineral wool on counter-battens with lining with sheets of gypsum fiber board, plywood.

This technology is relevant in frame, log, and panel houses. It provides insulation of the lower floor and allows the use of any floor coverings.

However, insulating the floor for a building on screw piles is not enough for normal operation. An excessively ventilated underground will lead to additional heat loss through the lower floor along the joists. The efficiency of underfloor heating will decrease and energy consumption in heating systems will increase. Climbing on piles using one of the methods below will relieve you from these troubles.

Floor insulation

Thermal insulation of floors in a house with a screw foundation is carried out in two stages: at the construction stage using the insulation method along the joists and during operation from the outside. Let's look at both options for floor insulation in more detail.

Internal insulation

Insulation of the floor from the inside in a house on screw piles is carried out using the method of insulation along logs. Conventional technology is used, which includes work in the following sequence:

- Cranial bars are packed along the lower edge of the joists.

- Then a rough base of boards is laid on these bars. They must be laid as tightly as possible, and the remaining cracks must be filled with foam.

- The next step is the installation of waterproofing material. For this purpose, roofing material or thick polyethylene film laid in several layers is used. Installation of waterproofing must be done with an overlap of at least 10 cm.

- Thermal insulation material is installed on the waterproofing layer. The materials used for insulation will be discussed below.

- The insulation is covered with a layer of vapor barrier material on top, after which the floor covering is installed.

The joists can be covered with floor tongue-and-groove boards or thick plywood. For additional insulation of floors, use linoleum on a thick base, carpet, or lay laminate flooring using a cork backing.

External insulation

During operation of a house on screw piles, additional insulation of the floor from the outside can be done. Let's study in detail the technology of how to properly insulate a floor using this method:

- Throughout the entire outer area of the house, a vapor barrier material is fixed to the bottom of the joists. It can be secured with glue or nailed with a construction stapler.

- After installing the vapor barrier material, a sheet heat insulator is installed, which is attached to the wooden base using self-tapping screws with disc-shaped caps.

Then the thermal insulation material must be covered with a wind membrane, which allows air and moisture vapor to pass in one direction: away from the thermal insulator, which allows it to breathe.

In some cases, the insulation of the floor on the outside of the house on screw piles is considered completed. But if desired, the heat insulator can additionally be covered with boards that are placed on the lower ends of the wooden beams of the base of the house.

Thermal insulation materials used

Modern technologies have helped to develop the latest highly efficient thermal insulation materials, which are used to insulate floors in houses on screw piles. Based on practical application experience, experts recommend using the following insulation materials:

- Extruded polystyrene foam. This modern insulation, perhaps, has the best performance characteristics of all the insulation used. Sheets of extruded polystyrene foam have excellent thermal insulation properties, are lightweight, easy to cut, and can withstand significant mechanical loads. In addition, expanded polystyrene practically does not absorb moisture, is not susceptible to rotting and mold, and has a long service life even in unfavorable conditions. The only disadvantage of this material is its fairly high price, which largely depends on the complexity of the technological process for manufacturing the insulation.

- Pressed basalt wool slabs have very low thermal conductivity and absorb various noises well. Light weight and installation also add to the popularity of this material. A significant disadvantage of mineral insulation is its hygroscopicity, which forces the use of multi-layer waterproofing during installation. That is why experts recommend using compressed types of wool for internal and external insulation of a house on screw piles. This heat insulator is more moisture resistant and durable, it is easier to install and secure.

- Polystyrene foam is low cost and light weight. Great for additional insulation. Due to its low cost, polystyrene foam is very popular. In addition, it has the following properties: low thermal conductivity, good moisture resistance, easy processing, durability.

- Foamed polyethylene on a foil base is used as a vapor barrier layer to protect the main insulation from external moisture. In addition, polyethylene foam enhances the thermal insulation characteristics due to the presence of a foil layer that reflects heat waves. Affordable price, easy installation and good performance properties make this material very popular.

Step-by-step algorithm of actions for self-insulation

Wood beams are stuffed on top of the assembled frame, boards are sewn on, forming a flat base.

Each tier of wood is immediately impregnated with antiseptics. When using polystyrene foam or penoplex, you need to lay a rough mesh with a sufficient margin of strength, otherwise the insulation will damage it with its own weight.

Then, they begin to waterproof the grillage with plastic film, roofing felt or membrane fabric. The material is laid overlapping, positioned so that the fabric sag slightly between the joists and is not stretched. Construction tape is used to seal the joints.

Information on proper thermal insulation of the floor of a wooden structure is shown in the following video:

Thermal insulation of the floor on the first floor

The insulating material is placed on top of the waterproofing so that there are no cracks or gaps between the parts of the layer.

A layer of vapor barrier film is laid on top to protect the thermal insulation from steam ingress and condensation formation. The flooring is also carried out with an overlap, the joints are connected with a construction stapler.

Insulation of floors in a wooden house

All that remains is to lay the laminate or lay the board on the prepared base.

An affordable but warm raw material is pine. More expensive, but denser in structure - aspen, oak. These types of wood produce durable boards characterized by durability, good load absorption, and low thermal conductivity.

When purchasing raw materials, it is necessary to take into account the wood moisture parameter - fairly dry boards have a value of no more than 20%. If you lay wet material, as it dries, the structure will begin to shrink - the boards will dry out, forming cracks, gradually becoming covered with cracks.

External insulation

A house on a foundation made of piles is located at a distance from the ground, so thermal insulation can be installed on the outside. This measure is resorted to if it is impossible to insulate the floor from the inside or as additional insulation from the cold.

External floor insulation

The vapor barrier film is overlapped from below to the joists, creating a gap of at least 10 cm. Fixed with staples and glue.

Thermal insulation is attached to a wooden base with self-tapping screws without seams, and the outside is covered with membrane fabric to protect it from external factors. The maximum level of protection is achieved with final planking.

Plinth as additional thermal insulation

An obstacle to the floor blowing is created by closing the base - the distance between the ground and the lower beam of the pile support grillage.

At the same time, it is possible to give the building a more decorative look - you can use sandwich panels, or simply stone or wood panels, which weigh much less than their natural counterparts. There is no need to rebuild the basement space; it is enough to complete the external cladding.

In addition to the absence of wind movement under the house, snow and rain will not accumulate below, which will extend the period of use of the structure.

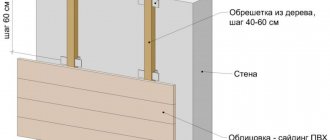

Base covering with insulation layer

Horizontal wooden slats of medium thickness are attached to the piles, creating a frame for the sheathing. On such a frame you can screw plastic panels, iron sheets, and other materials mounted on the sheathing.

An option is brickwork, which will create a durable, dense barrier to precipitation and wind. A layer of sand is poured in advance under the false plinth and compacted, and after finishing the work the masonry is covered with roofing felt.

Achieving the maximum thermal insulation effect is possible if the base is insulated.

Installation of insulation to the base

The basement can be insulated using three methods: from the outside, from the inside, or floor insulation.

For external insulation of the space, Penoplex or expanded polystyrene slabs are used.

Internal insulation can be made from sprayed thermal insulation, applying the material along the inner surface of the sheathing. Such protection does not form joints, quickly increases in size, and creates a sufficiently dense layer to prevent heat loss.

It is better to do the insulation of the floor right away, otherwise it is impossible to be at home without warm shoes. At the same time, the cost of heating the home increases significantly, and the risk of constant colds is higher. A reliable heated floor is the key to health and partial safety of the family budget. For example, when heating with gas, the cost of thermal insulation of housing pays off in 2-3 winters, provided that such a thermal barrier lasts longer.

If it is difficult to choose on your own, or you need additional information, you can seek the advice of a specialist.

The principle of insulating the base of a wooden building is shown in detail in the following video:

average rating

more than 0 ratings

Share link

Making a foundation fence

The foundation on screw piles is a prefabricated, stable and durable structure. It is used in flooded, swampy areas, as well as in areas with cold, harsh climates. The base of a house on stilts - the space between the sheathing of a frame house and the ground surface - should be properly insulated. Thermal insulation of a pile foundation reduces heating costs in winter and air conditioning costs in summer.

Thermal insulation of the base is not only a warm floor, but also the reliability, safety and durability of the building as a whole. It not only reduces heat loss in a frame house, but also insulates the soil underneath it.

In winter, the ground around the piles freezes. Heaving forces arising from the cold can push the piles out of the ground. As a result, the building may become distorted, which will compromise its stability and safety. Insulation of a pile-screw foundation protects communications connected to the house from freezing. Therefore, thermal insulation of the base is an important and critical stage of construction.

in individual housing construction.

Screw piles are one of the solutions for constructing a foundation. But there is an important circumstance that you should know about before installing a pile foundation: if your site has heaving or water-logged soils, then the ideal solution would be a shallow (insulated slab) foundation

Pile foundations are characterized by increased temperature loads on the lower part of the house. Simply put, a building on stilts loses much more heat through the floor than a house on a conventional foundation. This means it requires a more careful approach to insulation.

When building a frame house on stilts (screw or conventional), it should be borne in mind that in these buildings there is no base at the base of the walls as such.

In its place, a free space is formed, airy from all sides, called an underground (it is subsequently covered with decorative panels, which are a continuation of the decoration of the walls of the house)

Under a house installed on a pile-screw foundation, a free space is formed that needs to be closed and insulated

Insulating the floor in a frame house on stilts involves taking into account all the factors listed above.

In addition, in order to protect the heat-insulating material itself, as well as the internal living spaces of the house, from moist fumes, it is necessary to take care of reliable hydro- and vapor barriers as part of the “pie” being formed.

When constructing the walls of a frame house supported by elements of a pile foundation, there is no such familiar foundation element as a plinth. In this case, the underground can be closed with a decorative imitation of the base, the so-called “catch-up”, which does not take the load from the load-bearing frame and walls of the building.

Correct design of such a fence involves arranging an outside “blind area” made using special (cut-off) waterproofing.

The installation of a screw pile foundation can be decorated with a decorative imitation of a base

Regardless of the method of decorating the underground part of the frame structure, it is necessary to provide small openings (“vents”) in its design to ensure natural air circulation within the boundaries of the ventilated spaces.

How to insulate the floor of a house on stilts?

Floor insulation on stilts

The choice of materials for insulating the space under a wooden house on stilts is not small. The main condition is the product’s resistance to high moisture. The most popular insulation materials are: polystyrene foam, expanded clay, mineral wool, penoplex.

Each of them has its own pros and cons:

Styrofoam. The material is lightweight, inexpensive, easy and convenient to install. But when it is simultaneously exposed to water and frost, the polymer material begins to crumble and crumble

Therefore, when insulating an underground space with polystyrene foam, it is important to think about good insulation from water. Expanded clay. Also not the most expensive material

Anyone, even a novice builder, can insulate an underground space with expanded clay. The material is natural (foamed clay), absolutely non-flammable, not heavy. But expanded clay does not have the highest thermal insulation properties. Minvata. This material is even more afraid of water than polystyrene foam. When wet, it loses its thermal insulation properties; it is impossible to dry wet mineral wool. But the material is very resistant to the appearance of fungus or mold; insects or mice do not grow in it. Another important property of mineral wool is that it is completely non-flammable. The technology for installing insulation is simple; mineral wool is sold both in slabs and in rolls. It is better to buy in slabs, it has more density. Basalt wool perfectly absorbs noise and does not create a large additional weight load on the piles. Penoplex. Compared to polystyrene foam, polystyrene foam has higher strength and increased moisture resistance. Therefore, the higher price for this product is fully justified by its insulating characteristics and reliability. The sheets of this material are lightweight, cutting and installing them is not difficult. Penoplex does not rot and is not affected by mold.

In addition to insulation, you should also take care of additional materials for arranging the floor. To protect the floor covering from wind and moisture, it is better to spend more money but purchase modern special membranes. It's not difficult to install them. An ordinary polymer film is suitable for installing a vapor barrier layer. You will also need antiseptic (antifungal) impregnation for all wooden parts of the structure.

Popular types of thermal insulation materials

Ease of use is one of the most important criteria for choosing materials. Some of them are hard and can only be used on flat surfaces, while others are successfully used for thermal insulation of areas of complex shape. Before insulating the floor in a wooden house, you should choose the most suitable type of insulation.

When choosing a material, you must take into account the conditions under which it will have to be laid. Source pro-uteplenie.ru

Insulation in rolls

Insulation materials are supplied in this form, the base of which is balsa wood or mineral wool. The physical characteristics of these materials (softness and reduced density) make it possible to lay thermal insulation not only on a perfectly flat surface without any particular difficulties. Roll insulation can be laid with the smallest number of joints, which increases the degree of thermal insulation. In most cases, this type of insulation is susceptible to high humidity, so when installing it you should take care of waterproofing. Sometimes rolled materials have an outer foil layer that protects the material from moisture.

Rolls are easy to unwind on a flat surface Source kak-sdelat-fundament.ru

Plate materials

These are lightweight insulation slabs or mats that cannot change shape during installation. They are characterized by low thermal conductivity and low weight. Easily mounted on surfaces with minor errors.

The slabs can also be laid aloneSource zoubi.net

Liquid polymer thermal insulation

This type is a special composition that, when exposed to air, forms a hard foam structure. With the help of such thermal insulation, all hard-to-reach places and errors are filled. Among the well-known representatives of this type of insulation is penoizol, which is applied to the surface from a spray can using a special sprayer. The only drawback of liquid insulation is its high price.

Liquid insulation sticks to any surfaceSource alio.lt

Loose thermal insulation

This type of insulation is represented by bulk materials such as slag, expanded clay or sawdust. They fill the required volume quite tightly, and installation is possible both on a pre-arranged base and on ordinary soil.

When choosing a method for insulating a wooden floor covering, you should be guided by the efficiency of using the material and the financial benefits.

Least labor costs on flat surfacesSource kakpostroit.su

Step-by-step installation of a floor on a pile foundation

Let us describe the sequence of actions for arranging and insulating the floor of a frame on screw piles. Work begins after careful preparation of the wooden elements: treatment with an antiseptic and fire retardant compound.

Strapping device and lathing fastening

Let's assume that the piles are installed and the metal heads for fixing the beams are secured. Further progress of work:

- Drill four holes on each “bottom” of the screw supports.

- Lay waterproofing, for example, roofing felt, on the heads.

- Lay out the beams along the perimeter of the structure and connect the elements together “in half a tree.”

- Attach the beams to the heads with self-tapping screws.

- Insert the remaining beams inside the perimeter.

- Use steel staples to additionally connect the strapping parts.

- Check the horizontal placement of the beams.

- Fill the bottom of the beams with sheathing - a base for attaching the substructure.

Useful: How to calculate dew point

Rough base and thermal insulation

Lay sheets of OSB, chipboard or moisture-resistant plywood on top of the guide rails. If edged boards are used, they must be nailed perpendicular to the joists.

After preparing the subfloor, they begin to insulate it:

- Cover the base with waterproofing film.

- Place insulation in the cells between the joists. When cutting mineral wool, it is necessary to provide a margin of 0.5 cm on each side for the tightest possible fit and to prevent the appearance of cold bridges.

- Spread a vapor barrier membrane over the insulation with an overlap between the sheets. Tape the joints with construction tape.

The next steps depend on the type of floor covering.

Creating a thermal contour for the plinth

The installation of a floor in a house on stilts necessarily involves driving in the base. The following methods of insulating finishing are possible:

- Brickwork. The base is a cushion of crushed stone and sand. The fence is laid out in half a brick; reinforcement is not necessary. Ceramic or clinker bricks are used for work.

- Siding. Thermal plates are mounted on a lathing made of galvanized profiles or bars, assembled on piles.

- Profiled sheeting. Purlins are welded to the bored posts, which serve as the basis for attaching the profiled sheet.

- DSP. Sheet material is mounted by analogy with corrugated sheets. The outer part can be decorated with flexible tiles and porcelain stoneware.

Regardless of the chosen method of finishing the underground part, it is necessary to provide “vents” - openings for natural ventilation.

The blind area of the house is laid out from concrete screed, paving slabs or paving stones. When arranging, it is necessary to maintain a slope angle of 4° outward. It is imperative to seal the junction of the false plinth cladding with the blind area. This will prevent melt water and precipitation from entering the underground.

What types of subfloors are there in wooden houses?

- According to the lags. Most often used as a base for finishing floor coverings with low load-bearing properties: laminate floors, linoleum, parquet boards or piece parquet. In these cases, subfloors absorb loads and distribute them evenly over the floor area. Sometimes such floors are called the base; this name is used by inexperienced builders, but has the right to life.

- Under the logs. At the bottom of the logs, cranial bars are fixed; they serve as the basis for fastening the subfloor, insulation, and vapor and waterproofing.

- Along load-bearing beams. In our opinion, this is the most successful option, but it needs to be thought through at the stage of designing a wooden house. Why do we think this?

The distance between the floor beams is ≈ 1–1.2 meters, specific values and thickness values are calculated depending on the load. Then logs are placed on the floor beams with a distance of 40–60 cm. Why do double work, it is much more expedient to install the floor beams a little more often, while reducing their size. These same beams will serve as joists. What will happen as a result? Significant savings in materials.

If you calculate the amount of timber for beams and joists in the traditional construction option, then the second option makes it possible to achieve savings of at least 40%. At modern prices for natural high-quality materials (and only the highest quality lumber is used for this work), the savings in monetary transfers amount to significant amounts. Another undoubted advantage is the increase in the height of the interior premises; with the height of the logs within ten centimeters, this is a noticeable increase.

Any low-quality materials can be used for the subfloor, except if it serves as the basis for installing finishing floor coverings. These can be either pieces of boards, OSB sheets, plywood or chipboard, or unedged boards. The thickness of the materials does not matter; boards or slabs with a thickness of one to three centimeters can be used on one floor. Thermal insulation materials will be laid on it; for them, minor differences in the height of the base are not critical. Of course, unedged boards must be sanded; wood pests breed under the bark.

Elements of subfloors

The second important point for all subfloors is protection from the negative effects of moisture. Currently, there are quite effective antiseptics available, which need to be used to soak the boards at least twice.

Fire protection of wood

No antiseptic - no problem. Just sand the boards, the effect will be exactly the same. Treat the ends of the subfloor boards with particular care. Inattention to the ends is one of the main mistakes of inexperienced builders. They first lay the cut boards on the supporting elements, and then use a brush to treat two surfaces, forgetting about the ends. The ends of the wood absorb the largest amount of moisture; in this place all the capillaries of the wood are open.

Drying oil

Treating wood with drying oil

And one last thing. Keep in mind that no antiseptics will help if the underground of a wooden house does not have effective natural ventilation. The subfloor will sooner or later lose its original properties. You will have to change not only it, but also the entire floor covering.

If you are afraid of rodents entering through the air, place metal grilles on them. If it seems to you that in winter the floors in the rooms on the first floor are very cold due to the vents (and this may be the case), then close them during the cold period. But be sure to open all the vents as it gets warmer. Ventilation, by the way, is a prerequisite for the durability of the lower crowns of a log house.

Installation of vents in the foundation

Correct placement of vents

Floor construction

The optimal solution is considered to be a poured floor in a bathhouse on screw piles. In the cold season, it is necessary to carry out mandatory insulation of the entire structure.

We suggest you familiarize yourself with the correct way to go to the bathhouse

A large amount of water gets on the floor in the bathhouse, so it is necessary to increase its moisture resistance and trouble-free removal of used water. To do this, it is necessary to equip a special drain ladder. Through it, water will flow into the sewer pipeline or into the drainage system.

Diagram of a pouring floor in a bathhouse

To protect the subfloor from the accumulation of water, you need to install a concrete screed in it in the shape of a cone with an inclination towards the sewer or drainage system.

To prevent anything from rotting and moisture from accumulating, it is necessary to install a concrete bowl with a drain in the bathhouse

Draft level

Subfloor equipment: Plank covering, without cracks, treated with antifungal impregnations. It is lined with film materials to protect it from moisture from below, and filled with expanded clay.

The top is also covered with film. The use of roofing felt and other bitumen-containing coatings in the future can complicate life with the unpleasant smell of resin. The height of the drain pipes and passages under them at all floor levels are marked immediately.

Thermal insulation

Insulation is made from available material:

- Mineral wool (stitched mats, roll) – 0.25 m thick;

- Foam polymer, polystyrene foam (slab) – 0.15 m.

Related Posts

- Insulation of a veranda in a wooden house

- Insulation of a concrete floor in an apartment

- How to insulate the underground floor in a wooden house from the inside

- Electric heated floor in a private country house: installation features in a wooden and frame house

- "penoplex" under a warm water floor, the advantages of the material, methods and technology for its installation

- Floor insulation in a frame house

- Do-it-yourself installation of screw piles

- What is expanded clay? properties, production, application and price of expanded clay

- How to properly insulate a garage outside and inside with your own hands step by step

- How to insulate a concrete floor in a private house, do-it-yourself insulation of the concrete floor of the first floor

- Insulating a balcony with panoramic glazing: useful to know

- Using slag for floor insulation

- Optimal temperature for heated floors

- Isover thermal insulation overview

- Construction of a frame house on screw piles

- Step-by-step instructions for thermal insulation of floors with penoplex

- Do-it-yourself insulation of the loggia. if necessary? sequencing

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- Do-it-yourself insulation of a balcony from the inside in a panel house

- Subfloor in a wooden house: making a strong joist base for the finishing coating

- Step-by-step technology for pouring self-leveling floors

- Slab foundation construction technology

- Insulating the attic with foam plastic

- Insulating the floor on a balcony or loggia

- Insulation of a house made of 150x150 timber from the outside

Read with this

- Insulation of a veranda in a wooden house

- Insulation of a concrete floor in an apartment

- How to insulate the underground floor in a wooden house from the inside

- Electric heated floor in a private country house: installation features in a wooden and frame house

- "penoplex" under a warm water floor, the advantages of the material, methods and technology for its installation

- Floor insulation in a frame house

- Do-it-yourself installation of screw piles

- What is expanded clay? properties, production, application and price of expanded clay

- How to properly insulate a garage outside and inside with your own hands step by step

- How to insulate a concrete floor in a private house, do-it-yourself insulation of the concrete floor of the first floor

Stages of work

The sequence of work for laying thermal insulation material is relatively simple. The first step is to install the cranial beam. Fastened with nails or self-tapping screws flush with the beam. This is the base of the subfloor. Next comes the assembly of the subfloor. It is made from edged boards or OSB sheets (chipboard sheets can also be used).

The main feature of using piles in the construction of a frame house is the empty space from the grillage to the ground. Which contributes to significant heat loss during the cold season. Lack of heat leads to uncomfortable living and the occurrence of malfunctions that violate the integrity of the structure. To make your home warm and durable, properly insulate the foundation and floor at the base of the house. In this article you will learn:

- how to insulate the floor in a house on stilts;

- how to insulate the basement of a house on screw piles.