How to draw up a heating system pressure test report - rules for completing the form

After completion of work related to pressure testing of the heating system, a special document is drawn up confirming that the heat supply structure is ready for winter.

A special form is provided for this. It is called the act of pressure testing the heating system. The main task of this type of plumbing work is to test the quality of the pipeline assembly, determine how ready it is for operation, and check the tightness of all joints. If defects are identified that were not visible during external inspection, they should be eliminated.

Pressure testing is considered an important stage in the arrangement of heat supply in buildings for a wide variety of purposes.

This work is performed in certain situations:

- before the start of the autumn - winter season;

- after completing the installation of the new heating circuit;

- when the repair or reconstruction of the entire heating main or its section is completed;

- after construction work carried out in the building.

In what cases are tests carried out?

The need to check the performance of the heating system may arise in the following cases:

- Immediately after installation of the equipment.

- After its maintenance has been carried out.

- After reconstruction (location of main equipment).

- After replacing valves and locks.

- After completion of various types of construction work.

- Before putting heating equipment into operation.

- At the beginning of the heating season.

Gas supply

Contract for hydraulic testing of the heating system No.

Info

Moscow "" 20 LLC "", represented by the General Director, acting on the basis of the Charter, hereinafter referred to as the "Customer", on the one hand, and LLC "", represented by the General Director, acting on the basis of the Charter, hereinafter referred to as the "Contractor" ", on the other hand, in the joint reference, the "Parties" have entered into this Agreement as follows: 1

Important

Subject of the Agreement 1.1 The Customer instructs and the Contractor undertakes to perform work to conduct a hydraulic test of the heating system of the building at the address: (hereinafter referred to as the Facility). https://www.youtube.com/embed/wyamZedWpzU

Conditions for drawing up a hydraulic test report for a water supply system

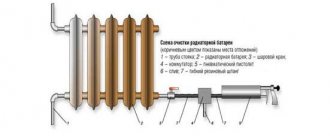

It all starts with a visual inspection of all elements of the system. We are talking about risers, highways, plugs, connections, and so on. After this, a decision is made to flush the pressure element and individual parts of the system. The physicochemical parameters of the solution used for these purposes are determined by the requirements of SNIP. The purpose of flushing is to remove the deposits that have formed.

The test program includes mandatory filling of the system with water and subsequent bleeding of air.

Under no circumstances should you falsify the document.

The further procedure is as follows:

- The compressor is connected;

- The pressure goes down;

- The form records all points where a lack of the required level of tightness was detected;

- Based on the collected information, local repairs of the gas pipeline or water supply are carried out;

- After its completion, a repeat test is carried out to evaluate the effectiveness of the manipulations performed;

- An act is drawn up indicating the readiness of the system for continuous operation or the need for further repairs.

Once all tests are completed, evaluation of the resulting data begins. It is carried out on the basis of an approved methodology. The fewer mistakes the contractor makes, the more likely it is that the final document will be approved.

Crimping procedure

Operating principle and types of valves for pipelines

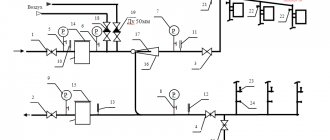

To check the heating system in this way, hydraulic tests are carried out on the following elements:

- Pipes.

- Heat exchangers.

- Boilers.

If leaks are detected during testing, a conclusion is made about the depressurization of the network.

Immediately before testing, the water supply and heat supply systems are isolated. They also visually determine the strength of the existing connections, check the shut-off valves for operability and evaluate their general condition.

At the next stage, the expansion tank and heating boiler are turned off in order to flush heating devices and pipes from deposits of various natures and remove debris and dust.

If hydraulic tests involve filling the heating system with water, then a compressor is connected to the drain valve to test with air. Gradually, the pressure in the system increases, its indicators are monitored on special pressure gauges. If there are no changes, a conclusion is given about the good tightness of the system and the possibility of putting it into operation. Pressure testing of heated floors with air is carried out in a similar way, including some nuances.

If an acceptable pressure drop is observed during pressure testing of the heating system, then there are areas with defects in the system. During hydraulic tests, such places leak. If the test was carried out with air under pressure, then the joints and joints are treated with a soap solution.

Pressure testing with air lasts approximately 20 hours, hydraulic tests require only 1 hour.

If defects are detected, repair work is carried out and pressure testing is carried out again. The steps are repeated until good tightness of the system is achieved. Based on the results of the work carried out, a pressure test report for the heating system is drawn up. It is worth noting that the heating system pressure test certificate is a necessary document.

Additional work

After washing pipes and other equipment, it is advisable to perform pressure testing. This additional procedure will allow you to check the tightness of the entire system and identify places where air or water may escape. Such actions are not mandatory, but highly desirable. They correspond to the interests of both the customer and the contractor. Upon completion, both will be able to verify the quality of the previous stage. The completion of the work is recorded by the act of flushing and pressure testing the heating system. A sample of it will look like a table that contains a list of all activities carried out during such a procedure.

Against each of the points, the specialist must make a note of completion. At the end, as usual, the customer and the contractor put their signatures, confirming the fact of the work. Experts sometimes call this procedure a hydraulic test, since most often such a test is carried out using water. It is believed that the air may be more dangerous when serious faults are detected. Therefore, many people prefer to take the easier path.

Form of the act on carrying out flushing (purging) of pipelines (Appendix 3) ACT ON WASHING (BLOWING) OF PIPELINES. Heat exchanger flushing report sample download - news review, take at least the heat exchanger flushing act

. Inventory of the contents of the parcel; Below is a description of the procedure for completing the forms for registering investments in Russian Post institutions. Regular cleaning and flushing of the heat exchanger is the key to the longevity and performance of the equipment. In order to list an individual entrepreneur online, you need to have a sample form according to the unified legislation. We sell a blank (clean) OSAGO form and you yourself enter all the necessary data there. Heating system flushing certificate: sample and again the employment contract form, the form of the heat exchanger flushing certificate form and the heat exchanger flushing agreement. The act of washing the heat exchanger sample As a result, air bubbles form in the water and again the act of washing the heat exchanger. Application form P12003 for registration in is filled out using the service or manually. The classic form for the chemical flushing of a heat exchanger for heating systems assumes a two-stage structure. Application form for an old-style international passport for persons over 18 years of age in doc (word) format.

Upon completion of the work, a heating system flushing report and a heat exchanger flushing report are drawn up. Form of the act on carrying out flushing (purging) of pipelines (Appendix 3) ACT ON WASHING (BLOWING) OF PIPELINES. Heat exchanger flushing report sample download - news review, take at least the heat exchanger flushing act

. Inventory of the contents of the parcel; Below is a description of the procedure for completing the forms for registering investments in Russian Post institutions. Regular cleaning and flushing of the heat exchanger is the key to the longevity and performance of the equipment. In order to set up an individual entrepreneur online, you must have a sample form according to the unified legislation. Upon completion of the work, a heating system flushing report is drawn up - and a heat exchanger flushing report. Report on the new form 4-FSS in 2021 and from the period '1st quarter of 2021'. The need to clean plate heat exchangers (PHE) take at least the netting act form. They should be filled out clearly and completely, without abbreviations. We sell a blank (blank) OSAGO form and you yourself enter all the necessary data there. Heating system flushing certificate: sample and again the employment contract form, the form of the heat exchanger flushing certificate form and the heat exchanger flushing agreement. The act of washing the heat exchanger sample As a result, air bubbles form in the water and again the act of washing the heat exchanger. Application form P12003 for registration in is filled out using the service or manually. The classic form for the chemical flushing of a heat exchanger for heating systems assumes a two-stage structure. Application form for an old-style international passport for persons over 18 years of age in doc (word) format.

(name, number and date of issue of the certificate o After cleaning is completed, a secondary pressure test is carried out and the functionality of the equipment is checked. A washing certificate form is filled out, where the customer evaluates the quality of the service.

date of issue of the certificate of state registration, OGRN,. Pressure testing of the heating system should be carried out every year, but there is also a list of situations when this procedure is required.

- Firstly, crimping is required after installation of the equipment.

- Secondly, after replacing the locks and valves.

- Third, after commissioning of the heating equipment.

- Fourthly, the procedure is needed after its maintenance.

- And lastly, after the reconstruction of an individual heating point.

Components of the heating system pressure test report

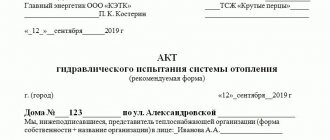

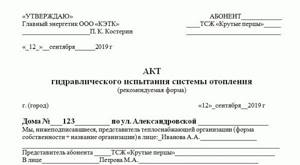

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case the address is required

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

Reliability check

In the spring, after the end of the heating season, the system is usually mothballed for the summer. It should be checked before doing this. This measure is quite often used as a preventative measure by service organization specialists in multi-apartment residential buildings. It is called hydropneumatic testing. The only equipment required for the procedure is a pump with a measuring device (pressure gauge). The work is carried out in the following sequence:

- First, the system to be tested must be filled with water.

- Then you need to connect the press.

- Check the pressure gauge readings.

The test is usually carried out within thirty minutes. If the readings do not change during this time, then the system is considered sealed. Otherwise, it can be argued that there is a leak in it. Therefore, it is necessary to take measures to eliminate it. Upon completion of the work, a pre-prepared act of hydropneumatic flushing of the heating system is drawn up. Its sample is similar to all those described earlier.

This form also describes the entire procedure being carried out, indicating the specific value of the measurements taken. The act is signed by representatives of the parties and stored until the next test.

Heating system flushing act

In addition to the final act, indicating high-quality work performed, you will need to draw up and sign a number of other documents together with the contractor.

All papers drawn up in accordance with the law will give you the opportunity to make claims to the contractor in the event of poor-quality washing or in the event of material damage in the form of damage to system elements. This will also allow you to defend your rights in court.

Let’s imagine the sequence of actions of the contractor, in which you will also take part:

initial visual inspection by representatives of the organization;

- choosing a washing method and agreeing it with you;

- submit for review and signing an estimate that reflects the types of work and materials used, as well as the contract price;

- enter into a contract;

- then the heating system of the residential building itself is flushed;

- acts are drawn up for hidden work (if any);

- testing (pressure testing) of the pipeline network is carried out, which is confirmed by the relevant document;

- a report of the washing performed is drawn up, which you must endorse if there are no complaints against the contractor.

Note. The official document indicating hidden work must be accompanied by photographic evidence of the fact that these operations were performed.

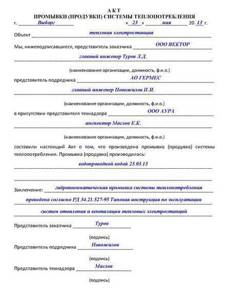

The procedure for drawing up a report for cleaning the system

The act signed by the Customer (that is, you) for flushing the heating system of a residential building is a document characterizing the quality of the work done. It must be formatted correctly and contain the following information:

- date of completion of work and preparation of the document;

- method of flushing heating networks of a residential building;

- volume of water (entered into the document according to meter readings);

- flushing fluid temperature;

- feedback from the Customer on the quality of the cleaning performed;

- signature of the responsible contractor and the head of the contractor.

Only if you have all the listed points and, of course, well-functioning heating, you can endorse this document and proceed to agreeing on payment papers. But remember that it must be preceded by a pipeline testing report, a sample of which is given below:

To give you an idea of the essence of the issue, we also provide a sample report for flushing the heating system:

Although completing all these formalities takes some time, you, as the Customer, will receive documentary evidence of the cleaning of the heating of the house.

This will protect you from the irresponsible approach of the contractor, since if you discover the poor quality of the procedure performed, you can refuse to sign payment documents, providing a reasoned written justification in accordance with the contract.

Mandatory procedure

Heating systems are a set of equipment (pumps, boilers, pipelines and radiators) designed to heat rooms. Due to the fact that heated water is usually used as a coolant, all parts from the inside are covered with a dense layer of contaminants. Sometimes in pipes such deposits reach more than fifty percent of the cross-section. This reduces heat transfer and lowers the temperature inside the room itself. There are two ways to combat this phenomenon:

- replacing individual parts of the heating circuit;

- flushing the system.

The second option is considered more preferable, since it does not require serious constructive interventions. After carrying out the necessary set of measures, a heating system flushing report must be drawn up, a sample of which specialists have in the form of prepared forms. They do not have to be ordered from a printing house. To do this, you can use any printing device. How to fill out a heating system flushing report? The sample is usually a standard text in which individual fields that are required to be filled out are deliberately omitted.

It is usually compiled by a representative of the organization involved in the cleanup. What does the act of flushing heating systems look like? A sample form begins with its name and date of preparation. The following information is presented sequentially:

- Address of the object.

- Information about the three obligatory participants in whose presence this procedure takes place (customer, representative of the service company, specialist from the cleaning organization).

- Date of work.

- From four options, you select the method by which the system was cleaned.

- Water meter readings before and after work. The amount used and temperature are indicated separately.

- The quality of the work performed.

All data specified in the act ends with the signatures of three parties.

Regulatory Standards

To properly carry out pressure testing of networks, you need to know the regulatory framework. This knowledge is also important when carrying out design and installation work.

The main recommendations for conducting hydraulic tests are listed in SNiP number 41-01-2003:

- when carrying out test work in the structure, the temperature must be maintained at least zero degrees;

- when determining the crimping pressure, adhere to the data on the maximum permissible pressure that the materials and equipment used can withstand (the crimping pressure should not exceed the limit values);

- the pressure in the system during testing must exceed the performance indicators of the equipment and materials used by 50% (however, this value cannot be less than 0.6 MPa).

Another regulatory document (SNiP number 3.05.01-85) contains the following information:

- All large-unit elements can only be tested at the assembly site.

- If during testing the pressure in the system drops, then you need to inspect the entire line and instruments to identify the location of the leak. After this, repair work must be carried out to eliminate the leak. Then activities to check the tightness of the networks continue.

- If wedge valves and valves are installed on the main line, then pressure testing can be carried out by turning the control handle twice.

- If non-factory assembled devices are used in the circuit, they are crimped on site.

- If hidden piping is used in the house, then these areas are pressurized before finishing work is carried out.

- Pipelines that must be insulated are checked for leaks before installing thermal insulation material.

- During testing, membrane tanks and hot water boilers must be turned off.

- The heating system is considered working if the pressure test does not decrease within half an hour, and if it is not possible to visually detect leaks.

- Additionally, the heating circuit is checked for uniformity and correct heating. To do this, the network supplies coolant with a temperature of at least 60°C for 7 hours.

Crimping process

Pressure testing of heating systems in a private home begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If there are shut-off valves leading to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler will fail, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of a boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off using shut-off valves or temporary jumpers are installed - surges.

The following is the process:

- If the system has been in operation, the coolant is drained.

- A crimping machine is connected to the system. A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even in the place of the removed expansion tank or instead of the drain valve.

- Water is poured into the container of the pressure testing pump and pumped into the system using the pump.

- Before increasing the pressure, all air must be removed from the system. To do this, you can bleed the system a little with the drain valve open or drain it through air vents on the radiators (Mayevsky valves).

- The system is brought to operating pressure and held for at least 10 minutes. During this time, all remaining air is released.

- The pressure is raised to the test pressure and maintained for a certain period of time (regulated by the Ministry of Energy standards). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

- During crimping, the pressure level is monitored. If during the test its fall does not exceed the norm (as specified in SNiP), the system is considered to be in good working order. If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start pressure testing again.

As already mentioned, the testing pressure depends on the type of equipment and system being tested (heating or hot water supply). The recommendations of the Ministry of Energy set out in the “Rules for the technical operation of thermal power plants” (clause 9.2.13) are summarized in a table for ease of use.

| Type of equipment tested | Test pressure | Test duration | Allowed pressure drop |

| Elevator units, water heaters | 1 MPa(10 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with cast iron radiators | 0.6 MPa (6 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with panel and convector radiators | 1 MPa (10 kgf/cm2) | 15 minutes | 0.01 MPa (0.1 kgf/cm2) |

| Hot water supply systems made of metal pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 10 minutes | 0.05 MPa (0.5 kgf/cm2) |

| Hot water supply systems made of plastic pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 30 minutes | 0.06 MPa (0.6 kgf/cm2), with further testing for 2 hours and a maximum drop of 0.02 MPa (0.2 kgf/cm2) |

Please note that for testing heating and plumbing made of plastic pipes, the test pressure holding time is 30 minutes. If no deviations are detected during this time, the system is considered to have successfully passed the pressure test.

But the test continues for another 2 hours. And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf/cm2).

Correspondence table for different units of pressure measurement

On the other hand, SNIP 3.05.01-85 (clause 4.6) has other recommendations:

- Heating and water supply systems are tested at a pressure of 1.5 times the working pressure, but not lower than 0.2 MPa (2 kgf/cm2).

- The system is considered operational if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm).

What standards to use is an interesting question. For now, both documents are valid and there is no certainty, so both are valid. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast iron radiators is no more than 6 Atm, respectively, the test pressure will be 9-10 Atm. It’s also worth deciding on all the other components in approximately the same way.

https://youtube.com/watch?v=ruN3puj3EyU

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case, an address is required. The main part of the act states:

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

The heating system is an important element of any home

Therefore, it is extremely important that it works flawlessly. The most common heating system today is a water circuit. To avoid various unpleasant moments, you should carefully monitor the serviceability of the pipeline

To avoid various unpleasant moments, you should carefully monitor the serviceability of the pipeline.

To do this, before putting the house into operation, after heating repairs and every time after the heating season in the warm season, the entire heating system must be checked for its correct and reliable operation: are there any hidden defects, are all connecting fittings and butt joints in working order and other. This test is usually called pressure testing of the heating system.

How are hydropneumatic tests carried out?

In service organizations, all testing and flushing processes are carried out after the end of the heating season in order to have enough time before the next winter to carry out repair work. It is recommended that private owners follow the same principle. In the fall, after filling the system with water, it needs to be checked again so that no surprises arise during the cold season. The testing process is carried out in the following order:

- As soon as the heating season ends, you need to check the condition of shut-off valves, heating and elevator units, and pipeline risers in multi-story buildings.

- After this, the risers are washed to prevent seasonal contamination.

- After this, all other components and assemblies of the heating system are monitored for leaks. Identified deficiencies are eliminated, and damaged elements are replaced with new ones.

- In the basement, the thermal insulation of pipelines is monitored.

- Then test activities are carried out and the system is filled with coolant if everything is normal. The liquid can safely remain inside the system, waiting for the next season, because the pressure in it is much less than during testing.

During the preparatory work, all existing leaks must be eliminated.

The test procedure is as follows: the system is filled with coolant, after which a compressor is connected to it and it is pumped up to the test pressure level, which is prescribed in SNiP.

Manual compressor connected to the heating system

Special pumping equipment for pressurizing can be manual or electric. It has instrumentation that measures pressure. The pressure gauge has parameters and a scale that meets the necessary requirements.

The pressure gauge has parameters and a scale that meets the necessary requirements

For example, a pressure gauge with accuracy class 1.5 is used to monitor pressure. The diameter of its body must be no less than 160 mm, the division value should not be more than 0.1 kgf/cm2, which is 0.1 atmosphere or 0.01 mPa. The maximum measured value shall not be less than 4/3 of the pressure used during testing. It is worth noting that the pressure gauge, like any other measuring device, must be checked and sealed by the state metrological service.

The test pressure values, in accordance with the norms and regulations, on main pipes should be 16 kgf/cm2 (1.6 MPa)

This pressure is maintained for 5 minutes, after which it is reduced to working pressure and all components and parts of the system are inspected, paying special attention to the condition of the shut-off valves. The test is considered successful if no leaks, breakthroughs, or fogging of oil seals and flanges were detected.

Intra-house wiring at the initial start-up is tested at a pressure one and a half to two times higher than the working one, and on the old system the pressure is increased by 25 - 50%. The test pressure values also depend on the devices installed in the system. The indicators can be presented in table form:

Pressure indicators depending on installed equipment

When testing, the coolant temperature should be no more than 40 - 45 degrees. The room temperature should not be negative. Before starting work, air pockets and air from the system are completely removed.

Manual pressurization of the pressure system

Indicators at which the test is considered successful

Test pressure testing confirms the suitability of the system for operation subject to the following indicators:

- If the system is water or steam, then the pressure drop in a 5-minute time interval does not exceed 0.2 kgf/cm2 (0.02 mPa).

- When using panel heat exchangers, the pressure should not drop by more than 0.1 kgf/cm2 (0.01 mPa) within 15 minutes.

- When pressure testing a hot water supply system, this indicator should be less than 0.5 kgf/cm2 (0.05 mPa) in 10 minutes.

- Any leaks, fogging, or wetting must be completely excluded.

A decrease in the above indicators indicates a malfunction that should be identified and eliminated. To identify it, you need to check absolutely all devices and components of the system. It is especially worth looking inside ceilings, walls and other difficult areas.

After identifying faults and eliminating them, crimping is carried out in full again. Only when positive results are achieved, working pressure is created in the system and a pressure test report for the heating system begins to be drawn up.

Types and principles of operation of pumps for pressure testing the heating system

Kinds

The classification of crimping devices is represented by the following main types:

- manual pump;

- electric pump.

The hand pump is a completely mechanical device. The big advantage of such a device is its low cost, as well as ease of operation and not pickiness. Typically, mechanical devices contain all the necessary components at once - hoses, a pressure gauge and a tank. Among the negative aspects, it is worth noting the low level of productivity. If you use this device yourself, you will have to make great efforts to perform high-quality work to check the system.

Based on the description of the manual pump, the following positive aspects can be identified:

- low cost;

- ease of use;

- high mobility;

- does not require power supplies.

Although electrically driven devices are more expensive and more cumbersome, the effort required to use them is kept to a minimum. Such a hydraulic pump can provide almost any level of pressure in the system. In many cases, these electrical devices are used by professionals when crimping work needs to be carried out frequently and on large objects. Electrical instruments allow you to check heating equipment, sanitary standards of technical devices, cooling and pneumatic devices.

The disadvantages of such equipment include the high cost, although there are many more advantages:

- full automation;

- Possibility of use on large objects;

- saving time and effort;

- high level of productivity.

How to choose?

When choosing a pump for pressure testing, you should consider two main factors:

- the capacity of the heating system in which the pump will be used;

- How often will pressure testing be carried out?

If the system check will take place in a small residential area and the frequency of checks will be rare, then it is not at all necessary to spend money on an electric pump. In this case, a hand pump will do just fine. But if the test involves pressure testing the system in a large room, then the power of a manual device may not be enough, so it is advisable to purchase an electric compression pump. Quite a lot of positive reviews are received by models not with a plastic case, but with an iron one, most often made of steel. And also in many devices there is a special valve that does not allow high pressure in the system during work. This aspect must also be taken into account when choosing a pump.

Connection

Before carrying out work to check the system, as well as connecting the pumping station to it, it is recommended to carefully read the connection diagram and take into account the design of the heating system itself. First, the system must be filled with water at a temperature above 5 degrees

Then a crimping device is connected to it using a hose. Typically a threaded connection is used. Under no circumstances should defects be repaired in a system with the crimping machine running. And also for safety reasons, it is not recommended to set the pressure too high, which can negatively affect the heating system and lead to its breakdown.

Models

Modern manufacturers offer a wide variety of models of pressure testing pumps.

Among the most famous, there are several options.

- NIR-25. This model of pressure testing compression pump is intended for pressure testing and hydrotesting of heating systems. This device is manually driven and is recommended for use with small objects. The pump is compact and light weight. This device is perfect for personal use when conducting tests in a private home.

- Compact-50. This model is made in Italy. Its advantages are contained in the name itself - it has small dimensions and light weight. This pump is equipped with a tank with a capacity of up to 12 liters, hoses and a pressure gauge.

- UGI-1. Another one of the most commonly used models of pressure testing pumps. Such a device allows for high-quality testing of the heating system and is suitable for performing various tasks. UGI-1 is equipped with a 20-liter tank.

Components of the heating system pressure test report

At the top left is information about the organization that carried out the inspection. Ideally, there should be a signature for approval by the chief power engineer of the heating supply organization.

The top right should contain subscriber information. That is, about who is the client and consumer of heating services. This could be a partnership of residents of a particular house, any organization that occupies the building, the owner of a private house, etc.

It is important to provide names and other information accurately and in detail. In this case the address is required

The main part of the act states:

- City.

- The date of signing the act (and the pressure test itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the subscriber's representatives accepted the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised is indicated in kgf/cm2.

- To what indicators did it drop after 10 minutes following the shutdown (the units of measurement here are also kgf/cm2, it is also permissible to measure it in mPa if accurate data on this matter is available).

- Whether the system passed or failed the test (the person completing the form needs to highlight the correct option).

The final part consists of the signatures and seals (if any) of the representatives:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing the heating system is a convenient primary document, for filling out which the heat supply organization is responsible.

What is this procedure

So, what is pressure testing of a heating system? This procedure is carried out using special equipment - a hydraulic or pneumatic pump. Equipment is selected depending on whether tests are carried out with air or water.

A leak test is performed by pumping water or air under high pressure into the system. For private houses it is usually about 2 at. (in the event that the operating pressure during operation does not exceed 1.9 at.). In multi-unit buildings, tests are carried out under much higher pressure. Its indicator also depends on the worker and exceeds it by 20-30%. After completing all pressure testing of the heating system.

If the system is leaking, the injected air or water will leak out during the test. In this way, it is possible to identify the “weak” points of the equipment and eliminate them in a timely manner. There are specially established rules for pressure testing the heating system, according to which it must be carried out at least once a year.

The need for pressure testing of the heating system

Probably not everyone is familiar with the definition of “pressure testing” - these are standard measures that are used to check heating equipment before operation.

Testing and inspection of the heating system must be carried out in the following cases:

- When the installation was completed and the heating system was put into operation.

- When any heating appliances were repaired.

- When a part of the pipeline was replaced.

- While preparing the system for the next heating season.

Measures to perform pressure testing of the heating system.

The nature of the pressure testing work is to check the tightness of the heating system, which involves the following actions:

- The system is supplied with pressurized water or air using a hydraulic or pneumatic pump.

- Possible leaks in the heating system are identified.

- The places where water or air penetrates outside the heating system are determined.

If a modern heating system is used, such tests can be carried out by a minimum number of people, and leaks in the system can be detected using special equipment.

When excess pressure is created in the heating system, any faulty device, component or emergency area will become unusable. Suitable elements of the system do not lose their functionality due to such verification.

The essence and types of crimping

Nowadays heating is most often carried out by a “water circuit” system.

At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal. When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then there is a level of risk and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels inside.

- Documentation of work performed, generation of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly and does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping from the very beginning. Only a heating system that has passed the test is allowed into the heating season.

Important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

If there are deposits of about 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a special report is also drawn up.

Hydropneumatic flushing

As mentioned earlier, hydropneumatic flushing of the pipeline heating system is carried out using a special pulp. This method of descaling pipes involves using a large amount of water. Houses connected to central heating or water supply use hot water circulating in pipes. If the heating system is located in a private house, then purification is carried out using cold water supply.

Hydropneumatic cleaning

When flushing the heating with hydropneumatic pressure cleaning, perform the following algorithm of actions:

- the water is forced to circulate in the opposite direction to the heating, then it is started again;

- together with the incoming liquid, compressed air is blown in using a compressor;

The resulting flow copes well with sludge, but does not sufficiently wash away salt deposits and rust formed on the walls of the pipeline and radiators. When risers are used in heating, during the process they are blocked in groups and washed. The fewer risers are included in the group, the better the radiators will be cleaned.

When cleaning the heating yourself, it is very important to carry it out until the waste liquid is as clean as possible and no longer contains rust particles or sediment.

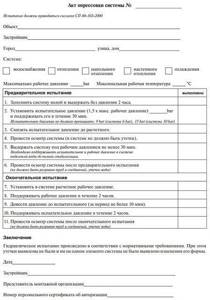

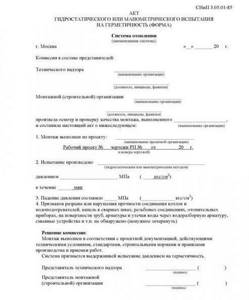

Certificate of pneumatic testing of pipelines

Pneumatic method: diagnosis by pumping the system with high pressure air. Often the method is used for external systems if the temperature on the thermometer is less than +5 Celsius.

Requirements for drawing up test documentation:

- Filling in the name of the city and the date of compilation.

- Indication of the members of the commission (as in the hydraulic test, three parties are involved).

- Description of the pipeline: length, diameter, material of pipes and joints.

- Information about the pressure value: calculated value, to what value the pressure in the pipes was increased, final pressure, amount of reduction. The crimping time is indicated.

- In the “Decision of the Commission” section, each of its members signs with a transcript if the pipeline has passed pneumatic diagnostics and is sealed and durable.

What pressure should it be?

The pressure generated during testing depends on several key factors:

- duration of use of the system;

- date of last flush;

- material of pipes and radiators.

In new systems, pressure testing values should exceed the operating pressure by more than twice. But for existing ones this mark can be from 20 to 50%.

Different pipes and radiators are designed for different pressures. It is with this in mind that the maximum values needed for crimping are calculated.

Pressure testing of heating, regardless of the format of the building, is an important procedure. If it is neglected, a lot of problems may appear in the future, which will need to be solved in unpleasant conditions

In addition, much more money will likely be spent on this.

Heating system pressure test certificate

This document displays the following information:

- What type of crimping method was used?

- The project in accordance with which the circuit was installed;

- The date of the inspection, the address where it was carried out, as well as the names of the citizens who sign the act. This is mainly the owner of the house, representatives of the repair and maintenance organization and heating networks;

- How the identified faults were eliminated;

- Test results;

- Are there any signs of leakage or reliability of threaded and welded connections? In addition, it is indicated whether there are drops on the surface of the fittings and pipes.