The Lemax gas boiler has long been known to consumers in Russia and the post-Soviet space. The equipment produced by the domestic company of the same name is capable of heating a house of any size, the main thing is to correctly calculate the minimum power. The manufacturer offers several series of heaters - with promising names Leader, Patriot, Wise, Prime-V and Wester Clever. Each series was developed for domestic conditions. All models have Russified automation, they are easy to maintain and operate.

Gas floor-standing boilers Lemax with a steel heat exchanger

This class is represented by five categories, each of which has its own gradation in terms of unit power. Thus, you can select the heating device to suit your needs as accurately as possible. The main thing is that the pressure in the heating system does not exceed 2 atmospheres. Let's look at the categories of heaters with a steel heat exchanger in more detail:

- Lemax premium boilers;

- premium nova;

- patriot;

- gas worker;

- clever.

Lemax premium steel boilers are divided into two groups. The first is from 7.5 to 60 kW, the second is from 70 to 100 kW. The units are made of steel 2 mm thick. For greater efficiency, the heat exchanger is made in the shape of a cylinder, just like Conord boilers.

The inner surface of the heat exchanger is protected with inhibitory compounds, which prevents the deposition of scale and salts.

The heater is non-volatile and equipped with Italian SIT automatic equipment. The smoke temperature in Lemax heating boilers is at least 110 degrees. Maximum water temperature 90 degrees. The unit operates at a nominal gas pressure of 1.3 MPa.

Some improvements have been made to the Lemax heating boiler of the premium nova series. The temperature regulator is now located on the front of the housing, and it is now possible to connect a thermostat and a turbocharger for the chimney. In addition, the heater is equipped with a soft start system. The power of the units in this series ranges from 7.5 to 30 kW.

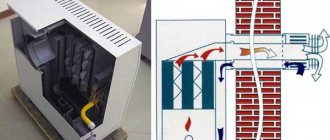

The peculiarity of the Patriot series boilers is that they have a closed combustion chamber. The unit does not need to be connected to the electrical network and does not require the installation of a full chimney. This is a parapet boiler that takes combustion air from the street through a special pipe (similar to a chimney). At both ends there are outputs for connecting to the heating system. Power varies between 6-20 kW. All models are single-circuit.

According to reviews, infrared quartz heaters for summer cottages are less reliable than carbon ones.

Read this article about how to choose a heater for your room.

The gas worker series is a classic AOGV with a power from 6 to 29 kW. Accordingly, the device is volatile, the combustion chamber is of an open type, the operation is controlled by a thermocouple. Compared to models of other series, the gas line has a slightly lower efficiency (87% versus 90%). The heaters are equipped with draft, gas and water pressure sensors. Available only in single-circuit version.

The clever series heaters have the widest functionality. An indirect heating boiler, indoor and outdoor temperature sensors, a turbocharger for the chimney, and a control unit via the Internet can be connected to the boiler. Thermal power from 20 to 55 kW. Consumes 9 W of electricity per hour.

Rules of service

Boiler installations carry potential dangers. Any actions to service the gas boiler and its elements must be carried out by specialists from the relevant service center.

Basic Rules:

- maintenance is carried out on a regular basis and at least once a year;

- Only a specialist has the right to disassemble and repair a gas boiler;

- all manipulations are performed only with the equipment turned off and de-energized;

- after turning off the heating device, before starting work, you need to wait some time for the coolant in the system to cool down;

- failed parts are replaced only with original spare parts.

The user can wipe the external surfaces of the heating system with a damp cloth as needed without using aggressive cleaning agents. The owner also checks and cleans the chimney if necessary.

Maintenance includes:

- diagnostics;

- checking the presence of draft in the chimney;

- cleaning the turbulator from soot;

- checking the tightness of connections;

- flushing the heat exchanger;

- disassembling and cleaning burners;

- checking the automation and traction sensor;

- measuring and adjusting gas pressure;

- inspection of parts for wear;

- replacement of failed elements.

Gas floor-standing boilers Lemax with cast iron heat exchanger

Heaters of this class can operate in heating systems with a pressure of up to 4 atmospheres. The wall thickness of the heat exchanger is 4 mm, which makes it very durable. Cast iron, unlike steel, is less susceptible to contamination, and its service life is much longer. There are two types of heaters in this category: leader and wise.

In a solid fuel boiler, coal is loaded through the top.

Lemax leader gas boiler, technical characteristics:

- non-volatile;

- power 16-50 kW;

- Efficiency 91%;

- overheat protection;

- traction sensor;

- maximum water temperature 80 degrees;

- nominal gas pressure 1.3 MPa.

The temperature control is located on the front part, with a pressure gauge located nearby. It is possible to connect a room thermostat. Thanks to this, you can set the required temperature in the room, which will be maintained at the same level. If necessary, you can install a fan to improve smoke removal.

Wise series boilers are connected to the electrical network, consumption is 7 W/hour. They can heat the coolant up to 90 degrees. They have an uninterruptible power supply installed, so voltage drops are not a problem for these boilers. The unit has connections for connecting an indirect heating boiler, various types of thermostats, and wireless control units. The option of switching to another type of energy carrier (liquefied gas) is also allowed.

Possible faults

The equipment of Taganrog manufacturers undoubtedly requires some improvements. Problems often arise with heating water - the devices cannot provide users with the desired amount of hot water in the required volume. Therefore, it is more profitable to buy a single-circuit device, and then connect a BKN to it - an indirect heating boiler. You can also choose a mounted or parapet (with a closed combustion chamber) boiler. Possible problems:

- The burner turns off spontaneously. The reason for this may be insufficient draft or breakdown of the thermostat.

- It smells like gas. Perhaps the leak is due to bad gaskets in the threaded connections - replacement is needed.

- Long, red-orange flame. Burners are clogged or there is insufficient draft.

- Cooled batteries with a hot boiler - there is not enough coolant or errors were made during installation.

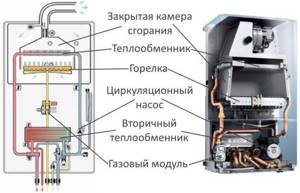

Gas wall-mounted boiler Lemax

The Lemax company produces only one line of prime-v wall heaters. Each device is equipped with SIT automation made in Italy. All models in this series are dual-circuit and can operate in heating systems with a pressure of up to 3 atmospheres.

Chimney of a parapet boiler.

The boilers are equipped with a closed combustion chamber, so they require the installation of a coaxial chimney. A fan is located above the combustion chamber. Turbocharging is needed to pump in air from the street and at the same time remove smoke outside. The maximum length of a coaxial chimney can be up to 5.5 m.

Mounted models

The wall range is more modest. All models are volatile. Automation - Italian production. Settings are factory settings. There is no need to adjust anything during operation. The main thing is to ensure voltage stability. If desired, the automation is connected to a block of remote thermostats. There is protection from:

- overheating;

- blowing out the fire;

- soot formation;

- reverse thrust.

Minus - there is no protection against freezing and pump jamming. The modulation burner, like the automation, is Italian. The modulation principle allows for economical gas consumption and increases the efficiency of the device. The connection is classic. Requires connection to a conventional chimney.

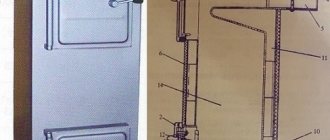

Solid fuel boiler Lemax

Solid fuel heaters are available in two configurations:

- solid fuel boiler – forward series;

- potbelly stove – series heat house and heat house-S.

According to reviews, the Lemax solid fuel heating boiler is designed to operate on coal. In this case, it is possible to use firewood and even natural gas as an alternative. In the latter case, you need to order a special burner. The peculiarity of this unit is the vertical loading of fuel, the hatch is located on top. Coal can be poured directly from the bucket.

The most economical heaters for an apartment are those that are equipped with good automation and thermostats.

About kerosene heaters for summer cottages is written here.

The TT boiler is available in three capacities (13.17 and 21 kW). Heats water up to 95 degrees, works in autonomous heating systems with pressure up to 0.2 MPa. The efficiency is quite low - only 75-80% for coal and 72-77% for wood.

Potbelly stoves are made from 4 mm steel. They come with a flat top and a basket for stones. The last option is used in doubles. The thermal power of both stoves is 10 kW. Weight 65 and 80 kg. Logs up to 60 cm long can be placed in the firebox. A potbelly stove can only be heated with wood.

Autonomous heating systems based on gas boilers are widespread in European countries.

In our country they are less popular, however, the situation is changing every year. Users are actively switching to heating using imported and domestic heating installations.

The choice of boilers is very wide, which makes it possible to choose the appropriate installation for any conditions or room size.

Let's consider floor-standing gas boilers produced by the domestic company Lemax.

Installation Requirements

Work on installing and starting the boiler is carried out only by gas service specialists. The installation of boiler equipment and chimney is carried out strictly according to the project approved by the supervisory authority.

Primary requirements:

- The boiler room area is at least 8 square meters. m.;

- natural ventilation is organized;

- there are no aggressive fumes or construction dust in the room;

- the heating system is installed and ready to start;

- there is sufficient draft in the chimney (checked with a candle or a special device);

- communications are connected to pipes located on the rear side of the housing;

- gas connections are checked for leaks using a soap emulsion;

- heating pipes are filled only with clean coolant, without impurities;

- Before starting the boiler, the room is ventilated for 10 minutes.

More details about installing and starting the boiler are described in the video.

Lemax floor-standing gas boilers

The Lemax company was founded in 1992 in Taganrog. Gas boilers produced by this company are assembled from imported components from leading European manufacturers.

Floor-standing boilers are non-volatile, operate on natural draft and do not need to be connected to the power supply, however, they have the ability to connect water heating units and turbo nozzles to create forced draft.

Lemax floor-standing boilers are presented in a large assortment; the model range has samples with a power from 6 to 100 kW, which allows you to heat apartments or large houses.

About the manufacturer

The Lemax trademark belongs to Lemax LLC (TIN 6154001478), registered in 1992 in Taganrog, the manufacturer’s address has remained unchanged to this day. The main activity is the production of gas heating boilers, but the company also produces water heaters and heating radiators. Products are distributed both through official dealers and through regular partner stores.

In addition to a large sales structure (due to demand, the brand is represented in almost all stores), the service structure is also developed, there is a hotline and a sufficient number of competent specialists in almost all regions of Russia.

The photo shows the Lemax Wise model.

In practice, boilers under the Lemax brand have really proven themselves to be reliable and trouble-free, having some of the best technical characteristics on the domestic boiler market. Often in private homes you can find models from 2005-2010 that are still working. The closest analogue is the Siberia model, which sparks debate about which of these two brands is more reliable and has a better price-quality ratio.

Review of Siberia gas boilers Some of the most reliable among domestic models

However, Lemax is the leader in demand, which can be explained by their well-known features. Gas consumption indicators are among the best among domestic models, for example, the maximum gas consumption of the most famous model Lemax Premium-10 with a power of 10 kW is 1.2 m3/hour, for Lemax Leader-16 with a power of 16 kW - 1.9 m3/hour. I would especially like to note the excellent build quality, which is not typical for domestic manufacturers: the gaps are even and minimal, everything is perfectly assembled and fixed, connections and bends do not rust even after 4-6 years of operation.

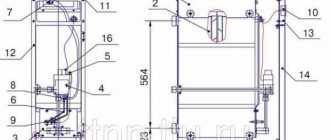

The device using the example of the Lemax Leader model.

The boiler design is standard for most domestic models: the famous Italian EuroSit automatic system and Polidoro burners. This design means that there is simply nothing to break in it. Steel heat exchangers are made of high-quality steel, which until today does not raise questions, but its thickness is only 2 mm versus 3-4 mm for analogues. Reliable and time-tested, but the fact remains a fact.

A more noticeable disadvantage is the high demands on connection, installation and configuration. Installation of Lemax boilers is somewhat more complicated than its analogues and requires certain competencies. It would not be worth focusing attention on this if it were not for the fairly frequent cases of incompetence of employees of Gorgaz, Oblgaz, etc., who make mistakes in organizing the wiring of boilers, which can lead to problems with the startup and operation of the automation (it may be necessary to replace the damaged wiring with factory).

Boilers are also demanding when it comes to the initial adjustment of the burner: if the gas pressure is too strong, frightening pops are possible when igniting; if the gas pressure is too low, there will be problems with igniting the main burner. It is especially important to comply with the requirements for the chimney: if there is insufficient draft, the draft sensor is triggered and the boiler goes out. Also, the boiler goes out even at the slightest reverse draft. However, this phenomenon is typical for all atmospheric structures that are not protected from backdraft and is only possible if there are errors in the design of the chimney.

Otherwise, the main rule is to carefully comply with all requirements, carry out installation and commissioning work correctly. According to reviews from owners and installation practice, all well-tuned boilers, regardless of the model, operate without problems for 10 years or more.

Advantages and disadvantages

The advantages of Lemax floor-standing gas boilers include:

- Simplicity, reliability and durability of the design.

- Non-volatility, increasing stability and reliability of operation.

- Ease of Management.

- Low fuel consumption.

- Relatively low price with high quality components.

- It is possible to only heat the home, or additionally prepare hot water.

There are also disadvantages:

- Ignition of Lemax boilers is quite difficult, especially if you lack the skill.

- Natural cravings are very unstable and depend on many external factors.

Disadvantages are common to all energy-independent models of gas boilers. However, they are many times compensated by undoubted advantages, so it is more correct to consider them design features.

Which boiler from the model range to choose

Consumers have a somewhat contradictory opinion about Lemax boilers: some praise them for their unpretentiousness, inexpensive maintenance and reliability, others criticize them for the occasional failures and malfunctions. The manufacturer has been manufacturing heating systems for decades - this alone deserves trust. As for problems, as the experience of service center workers shows, they occur in almost all models and depend little on the brand.

When choosing a unit, owners should consider the following conditions:

- the boiler must have a power reserve;

- 1 kW approximately corresponds to 10 m2 of heated area;

- level of heat loss in the house.

The range of heating equipment is constantly expanding, new, productive and reliable products are appearing. The obvious advantages of Lemax brand boilers include the fact that a solid repair base has been formed for them, the main “problem” areas have been identified and the restoration of faulty equipment is not a problem. Moreover, most major problems can be fixed at home, without turning to specialists for help.

What series and models are floor-standing

The Lemax group of floor-standing boilers includes the following series::

- Patriot . There are 6 models available with a power from 6 to 20 kW, which is optimal for apartments or small private houses. Parapet-type units are equipped with convection openings in the body, allowing the room to be heated. If such a boiler is in the kitchen, radiators will not be needed. A coaxial chimney eliminates the need for labor-intensive connections to a common house pipe.

- Premium . The series consists of single- and double-circuit models of floor-standing gas boilers with a power from 7.5 to 100 kW. There are 22 models in total. Double-circuit units have the letter B in their name. The most capacious series, allowing you to select the right boiler for any room or operating conditions. The simplicity of the design makes them very reliable and durable, and the low gas consumption contributes to the popularity of this equipment.

- Premium N. They differ from the basic Premium series by the presence of a gas valve 820 Nova Sit. The remaining features and parameters are the same as the main line models, but the power of the models is limited to 35 kW.

- Wise . These boilers are new, they appeared relatively recently. Made from ductile gray cast iron. They have 5 models with a power of 16, 25, 35, 40 and 50 kW. Single-circuit models with a sectional heat exchanger. They differ from conventional series in the need to connect to the power supply network.

- Leader . They are also a new product in the Lemax model range. Non-volatile single-circuit boilers with power from 16 to 50 kW. The cast iron sectional heat exchanger allows for high efficiency of thermal energy transfer.

Advantages

Judging by customer reviews, Lemax products evoke positive emotions due to their performance, design and efficiency. The main positive aspects of solid fuel and gas boilers are:

- High efficiency, reaching 92%.

- Stylish appearance. The devices look good in modern interiors.

- Safety of operation and switching on due to multi-stage protection.

- Easy to connect and use. It is easy to light the boiler and turn it off.

- Duration of work reaching 25 years.

- Production of single- and double-circuit devices.

The company manufactures floor and wall heaters.

Specifications

Let's look at the table of the main technical characteristics of Lemax floor-standing boilers:

| Characteristics | Values |

| Boiler type | Gas |

| type of instalation | Floor |

| Type of fuel | Natural, optionally liquefied gas |

| Thermal power | 6-100kW |

| Efficiency | 87 -93% |

| Gas consumption | 0.38 – 2.6 m 3 /h |

| Maximum coolant temperature | 90° |

| Diameter of coaxial chimney | 250-310 mm |

| Chimney length | 330-800 mm |

| Water pressure in the system nom/max | 1.5/2 Bar |

Brand Lemax

Today, Lemax is the largest manufacturer of heating equipment, mainly specializing in gas boilers. It was opened in the city of Taganrog in 1992 and within a few years it grew from a small manufacturer into a reputable company.

At the very beginning of its activities, it acted as an intermediary between manufacturers and buyers, and after a while it became a large manufacturer of boilers, radiators, boilers and other related equipment. The company's dealers work successfully not only in Russia, but also abroad.

The manufacturer offers a large line of heating equipment, but floor-standing gas boilers have gained the greatest popularity and demand.

Device

Lemax floor-standing gas boilers have a heat exchanger in the form of a welded or cast iron container that forms a water jacket around the combustion chamber.

A gas burner is installed in its lower part, and under it there is a gas valve, control devices and connecting pipelines . The upper part of the heat exchanger has a passage for installing a chimney, which can be of a classic or coaxial design.

The connections for connecting the heating circuit for different models are located either on the sides or on the back of the boiler. There is also a hot water supply pipeline (for dual-circuit models).

The operation of the unit consists of the coolant entering the heat exchanger tank, heating and exiting independently under the influence of gravity - the density of the heated layers decreases somewhat, which helps to displace them by colder layers of liquid.

Self-circulation of the coolant is based on this effect. Hot water is heated in a copper coil installed inside the heat exchanger .

Smoke removal occurs under the influence of natural stove draft.

How to turn on and light: brief instructions

If on volatile models with electronic controls, starting the boiler is intuitive and consists of pressing several buttons, then on budget non-volatile models with EuroSit automation this is a more complex algorithm:

- Before lighting the boiler, make sure that the gas supply valve is open, check the draft in the combustion chamber, for example with a match.

- Set the mechanical thermostat (rotator) to the “Off-0” position, and then counterclockwise all the way to the “⭐” position.

- Press and hold the magnetic valve button (the start button in the center of the thermostat) for 30 seconds, then press the piezo ignition button near the thermostat once without releasing the start button. At this moment the pilot burner should light up; if this does not happen, repeat the steps. If the wick burns steadily, continue to hold the trigger button for 30-60 seconds, after which you can gradually release it.

- Rotate the thermostat to set the desired power level (1 – minimum temperature, 2 – maximum temperature).

The appearance of the controls may vary slightly depending on the automation (630 EuroSit, 710 MiniSit or 820 NovaSit). The detailed algorithm is always described in the operating instructions.

How to completely turn off the boiler

- Turn the thermostat to the “⭐” position. The main burner should turn off, but the pilot burner (wick) will burn.

- To completely turn off the gas supply, turn the thermostat knob to the “Off-0” position, and then do not forget to turn off the gas supply valve.

User manual

Operation of Lemax floor-standing gas boilers comes down to igniting the burner as needed and setting the desired temperature. All other operations - replenishing the volume of water in the heating circuit, installing a chimney, connecting a boiler - are performed without interfering with the boiler design.

To ignite the burner, turn the regulator to position 1, which means switching on the operating mode. Then you need to push it all the way and hold it while pressing the piezo ignition button.

When the pilot burner lights up, the button is released, but the regulator is held for about a minute.

Periodically it is necessary to clean the internal components of the boiler from carbon deposits and soot . You also need to monitor the condition of the heat exchanger, gas valve and other components of the unit.

Periodic maintenance should be performed by specialists from the service center. It is not recommended to do this work yourself, especially if the warranty period has not yet expired.

Boiler installation and setup

In order for the Lemax boiler to function without problems or breakdowns, it is important to install and connect it correctly. The installation should be entrusted to professional workers, especially if the user does not have the skill to connect heating equipment.

The main installation requirement is to ensure intensive removal of combustion products. The manufacturer recommends attaching a draft device made from sandwich pipes to the chimney.

Startup and connection are simple and quick. Factory settings are suitable for operation; they can be adjusted mechanically.

The gas valve plays an important role in the automation unit. This is a device that controls sensors or controllers that receive information from sensors. The product may consist of two valves - conventional and electromagnetic. When starting, the second one opens by pressing the button to ignite the wick. The user can then release the button. When the igniter is blown out, the thermoelement cools and the valve closes. The other spring valve will close after receiving a signal from the draft and temperature sensor.

Malfunctions and their causes

Sometimes when using gas boilers, malfunctions occur. This is true not only for older models, but also for those that have served their owners for a relatively short time.

Here is a list of the most common problems:

- the boiler does not turn on;

- the unit switches off very often;

- in some cases you can see that it has completely gone out;

- the boiler turns off completely or goes out very quickly, resulting in smoke;

- The burner does not light well and it takes a long time to turn on.

It is necessary to consider why this happens and what to do in these cases.

- For example, if the draft in the boiler is broken or there is no draft at all, then a constant flame cannot be maintained. To check the presence of draft, you need to light a match and carefully bring it to a special testing window. If there is traction, the fire will deviate in any direction. If it is not there, then the fire will burn quite evenly. If there are such problems, then you need to clean the chimney.

- Sometimes the draft, on the contrary, is too great, in which case the flame will also die out. This can also be corrected: it is necessary to install dampers to reduce traction.

- There are cases when the chimney shaft becomes covered with ice, which interferes with the full circulation of water. This usually happens in very cold winters. To solve the problem, you first need to knock off all the ice, and then insulate the pipe from the outside. After this, the system should work without interruption.

- If the burner does not light up for a very long time, the reason may be a faulty sensor. To understand whether this is so, it is necessary to short-circuit the opposite terminals with each other; if nothing lights up, you need to change the sensor.

- There are times when smoke comes out from behind the boiler door. This occurs if the gas does not ignite immediately. To eliminate this problem, you need to adjust the air flow to the burner. To do this, you just need to find the adjusting washer and move it in one direction or another.

- Injectors often fail. This usually happens during repair work, then the gas flows partially. To eliminate this problem, you need to either repair the nozzle or replace it with a new part.

- It happens that in warm weather gas boilers can fail. The reason is that the temperature outside and in the chimney are different. To prevent this from happening, you need to warm up the chimney at least from time to time.

What devices use bimetal?

The scope of application of the bimetallic strip is extremely wide. Almost all devices where temperature control is necessary are equipped with bimetal-based thermostats. This is explained by the design simplicity and reliability of such relay systems. In our usual technology, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electric packages there is automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- In thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from temperature overloads: transformers, electric motors, pumps, etc.

Rules for operating a heating system based on AOGV

Before choosing an AGV, you need to familiarize yourself with the basic rules.

The boiler should be installed in an isolated room, since turning on the unit is accompanied by a loud bang. Some modifications can boast of partially eliminating this problem. In them, after heating the water to a certain temperature, the burner does not turn off, but switches to the minimum flame mode.

To connect the boiler, you should invite a gas service specialist, who will simultaneously register the device.

It is best to place the AGV in the lower part of the house, and the ascending pipeline must be insulated. In this case, the return pipe does not need insulation.

The heating system elements responsible for heat transfer should be located at the maximum possible height from the main AGV element. It is considered optimal to place radiators or heating panels under the windows, this ensures the circulation of layers of air. It is recommended to place the return pipe under the floor; in this case, the risk of “airing” the system is minimized.

The flawless operation of the AGW-based system is ensured by two-inch network pipes, which do not have a very aesthetic appearance

When replacing these elements with pipes of smaller cross-section, there are some consequences to be taken into account. The fact is that a smaller pipe diameter increases hydrodynamic resistance, which in turn leads to a decrease in water pressure in the system.

When solving the problem of whether a gas boiler or an AOGV is better, it should be taken into account that the efficiency of operation largely depends on the correctly selected pipeline slope. The recommended slope is 1 cm per linear meter of pipe. In this case, less air pockets form in the system, the coolant circulates more freely, and it becomes possible to unhinderedly drain water from the system.