Standards for installing gas mounted boilers

There are regulations that specify construction rules for installation.

First you will have to fulfill all the conditions specified in these documents:

- Call the gas workers so that the specialists check the existing conditions and, if the rules are followed, allow the connection of the unit to the central main line of the house.

- Draw up the project correctly to avoid a fine. An exception is that the heat generator has already been installed in the house and you only need to replace it with an identical model.

As soon as the project is completed, it is necessary to contact the state supervision authorities with papers. After checking, they issue permission to install a wall-mounted boiler.

Then you need to fulfill a few more mandatory conditions - choose the right height and comply with the requirements. security.

Height

When installing the boiler on the wall, you must follow the rules for selecting the optimal height specified in the SP. It says that from the floor to the bottom of the purchased boiler the distance should be 0.9 meters (minimum), but not more than 1.2 meters. It is important to note that these parameters are used for boilers, but gas manufacturers often impose these requirements on boilers as well.

It is important to comply with the minimum height established by gas workers, which is calculated by the distance from the chimney pipe. Official regulations indicate that a wall-mounted device will have to be lowered by 2 diameters (minimum value) of the chimney.

Fire safety standards for installation

When installing a wall-mounted gas boiler in an apartment, it is necessary to comply with safety standards.

Therefore, it is necessary to set fire breaks (minimum indicators that should be adhered to are indicated):

- The distance from the equipment to the wall is at least 10 cm.

- From the opposite wall - at least 40 cm.

It is necessary to install a protective non-combustible partition between the room with a single-circuit wall-mounted boiler and the residential part. It must have an increased degree of fire resistance for the safety of household members. When connecting equipment, it is necessary to use a corrugated metal pipe. It is strictly forbidden to purchase rubber hoses for boiler installation.

Installation on different walls

Boilers are quite heavy, and therefore problems can arise if you do not take into account the reliability of fixation to the wall. There are certain standards for installing boilers, which indicate that installation work must be carried out only on a rigid wall.

Requirements may vary greatly depending on the material that was used to build the walls in the house. There are standards for wooden, reinforced concrete, plasterboard and brick surfaces.

Installation on a reinforced concrete wall

Reinforced concrete walls are the most suitable option for installing a wall-mounted gas boiler. They have increased strength and are completely non-flammable. Therefore, there was no need to use additional methods of protection in the form of cladding. To fix the heat generator body, metal anchors are used, onto which the mounting plate is fixed. After this, the unit is installed on the prepared site. Any type of heating system can be installed on concrete walls: those with high power or a conventional storage-type broiler.

Installation on a brick wall

The installation standards separately stipulate the conditions for fastening to a brick wall. Brick is another high-quality non-combustible material, and therefore the equipment is installed directly on the wall, but this time you will have to prepare the surface.

In order not to violate the requirements of gas workers, the wall must be plastered before installation work. During this work, you will need to install a special strip. After finishing the plastering, two bolts should protrude from the wall, which serve as a seat for the equipment.

Is it possible to hang a boiler on a wooden wall?

Installing a wall-mounted gas boiler in a wooden house is a difficult task due to a number of nuances. A wooden wall can catch fire, so you need to take safety precautions.

To properly install a heating boiler, you will have to fulfill several special conditions:

- Carefully treat the wood at the installation site. It’s quite easy to do this with your own hands - there are special fire retardants in hardware stores. They will need to treat the wall generously.

- The wall must first be covered with plaster (thickness – 15 mm). This is the minimum value that guarantees protection against high temperatures. You can also line the wall with roofing steel.

If you do not want to use plaster or metal cladding, you can put a gypsum fiber board in the place where the heat generator is mounted, and then cover it with ceramic tiles.

To prevent a heavy heating boiler from falling from its installed place, it is necessary to strengthen the platform with a powerful beam, which is placed under the facing material. Thus, it will be possible to securely fix the heat generator on the wall.

Can it be hung on drywall?

When installing drywall, voids cannot be avoided. This creates problems with fastening a heavy heat generator. However, there is an option to eliminate this shortcoming.

When the metal frame is being manufactured, it is necessary to select in advance a place to fix the boiler and carry out preparatory work. It is necessary to reliably strengthen the site using wooden beams and metal profiles. For installation on fragile drywall, special fasteners are used. These are plastic plugs that are screwed into the facing material. The hardware must be mounted into the already installed plug. Experts say that ready-made fasteners gradually become loose, which leads to deterioration of fixation.

Mounting the boiler on foam concrete and aerated concrete

If the house is built of aerated concrete or foam concrete, then several methods can be used to install the boiler:

- The fastenings are installed in advance at the moment when the blocks are laid. The boiler is installed when the masonry mixture has completely hardened.

- In stores you can find screws for fixing in foam concrete. They are very similar to the cork used for drywall. But they have a deeper thread and a larger pitch. As soon as the material is screwed into foam concrete or aerated concrete, any anchor can be installed in the screws that will reliably hold gas equipment.

- Another reliable method of fixation is with studs. They are installed with a small gap from each other, and a strip is mounted into the wall (on each side), which is firmly fixed with bolts for maximum reliability.

- You can also use liquid, chemical anchors. They provide a strong hold, but are more expensive than previous options.

Design and principle of operation

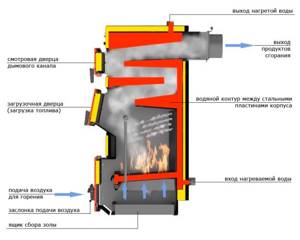

On the modern market you can find a huge number of models of solid fuel boilers, but their design and operating principle are not much different. Any equipment for heating rooms consists of the following parts:

- fuel combustion chamber;

- chimney;

- ash collection chamber;

- coil or heat exchanger.

The simplest models of solid fuel boilers are somewhat reminiscent of a potbelly stove. After the wood burns, the flame heats the pipes with water, the liquid is heated and enters the double-circuit heating system. The efficiency of the models is low, and fuel consumption is significant.

Modern units have an improved design; they are equipped with automation that regulates the combustion process. After fuel combustion, heated water is supplied by a circulation pump to the radiators. Heating devices give off part of the heat, the liquid is cooled and flows through the return pipeline into the boiler. Modern heating systems are often equipped with a closed expansion tank, which avoids water evaporation during heating.

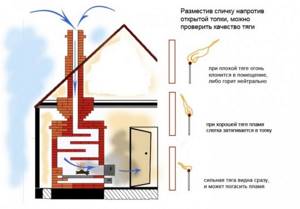

During the combustion of wood, smoke is generated, which is discharged to the street using a chimney. After some time, soot settles on the walls of this structure, which leads to a decrease in the diameter of the pipe and a deterioration in traction. To clean the chimney from dirt, special openings with dampers are used. Soot is removed from the canal using special brushes or brushes.

Note! To clean the chimney from soot, you can use special solutions that are added to the fuel. They allow the inner walls of the pipe to be cleaned during the combustion process.

Automation helps increase the efficiency of a solid fuel boiler:

- the temperature sensor is triggered when the coolant temperature drops, it sends a signal to the control panel to turn on the fan;

- the pressure gauge gives a signal when the pressure increases above normal levels;

- to prevent emergency situations, a bleed valve is installed in the system;

- the circulation pump begins to pump water after heating the coolant in the boiler to certain temperature parameters.

The efficiency of the boiler depends on the type of fuel used. If the unit is designed to operate on wood, then coal or pellets cannot be used. It is also not recommended to use insufficiently dried firewood; they provide little heat, but produce a lot of soot and water vapor.

Premises requirements

The first task is choosing the installation location. The basic standards are set out in SNiP 02/31/2001. Installation in residential areas, bathrooms or toilets is prohibited. Installation in the basement room is possible, but not in the basement. It also cannot be installed in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room.

It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a power of up to 60 kW can be installed in a room with the following parameters:

- Minimum volume – 15 m?. For every kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling heights are from 2.5 m and above.

- Availability of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The installation site is isolated from the living quarters by a door; if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings – 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

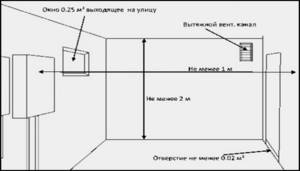

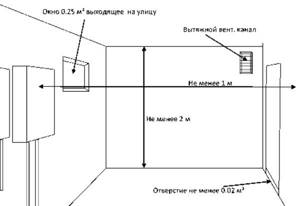

In addition to the door to the street, there may be an additional doorway into the house. It is important to ensure tightness - combustion products should not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the air exchange value should not be less than 3 boiler room volumes per hour. Additionally, combustion air consumption is taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation hole is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? 0.03 m required? light opening. Important - this is an indicator of the net influx of light, without taking into account the width of frames and imposts.

General requirements for the installation of gas appliances

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: per 1 m 3 there must be at least 0.03 m 2 of window opening area (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for room volume:

| Gas boiler power | Total combustion volume |

| 3 | |

| > 30-60 kW | 13.5 m 3 |

| > 60-200 kW | Requirements according to the conditions of installation and operation of a gas boiler, but not less than 15 m 3 |

For gas-fired units with a power of more than 6000 W, 0.2 m3 should be added for each extra unit of power.

Supervisory requirements for the premises for installing a gas boiler stipulate that the operation of any appliances for heating an apartment is permitted on each floor of a multi-storey building and in any room of the apartment. Kitchens in multi-storey buildings also meet these requirements, since they are already equipped with appropriate communications. The only condition is that the total thermal power of all devices for heating water and heating the apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed a total of 150 kW.

The ceiling height in the room is 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from adjacent rooms by solid fire-resistant walls. Material for walls or partitions must have a fire resistance time limit of 0.75 hours (45 minutes). The boiler room must be designed so that in the event of an operational fire there is no possibility for the fire to spread throughout the apartment.

Gas boilers of the TLO brand, operating on the principle of natural coolant circulation, can be installed and should be operated only in the basement of the house or in the basement.

Permits

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. Connection to the gas main should only be carried out by certified specialists, but installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining technical conditions. It indicates the requirements for connecting to the gas main. It is necessary to provide a house plan with its characteristics.

- Drawing up a gasification project. This work is performed by specialized licensed organizations.

- Based on the project, permission is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, representatives of the gas service must check the building and the main line for compliance with the technical conditions and the agreed project. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of Gorgaz subsidiaries. Their representatives know the nuances of design and the latest changes in requirements for premises and equipment.

Installation diagrams

After preparing the premises and obtaining permits, you can begin installing the boiler. The equipment installation site is finished with fireproof materials. For wall-mounted models, the use of reliable fasteners is mandatory.

How to hang a gas boiler on a wooden wall, and what standards must be followed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the pipes for connecting to the pipeline and the location of the gas main are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for domestic hot water, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side ceilings this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling 45 cm.

- The hole in the interfloor ceiling or wall for the chimney is protected by a special fire-resistant sleeve. Its function is to prevent direct contact of wood with the heated surface of the chimney.

- Use of plastic pipes in heating. To protect the surface of the main from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-burning boiler in a wooden house will be easier. But in the future, heating and maintenance costs will be higher than for gas heating.

Recommendations for effective operation

During operation of a wood-burning boiler, slag accumulates in the furnace of the installation. As they accumulate, such combustion waste must be removed, because it reduces the efficiency of the unit. A decrease in efficiency by 3% is possible with the formation of a slag deposit 1 mm thick.

It is necessary to clean the walls of the boiler combustion chamber at least once a week. At the same time, the wheel gratings are cleaned. To get rid of ash and other accumulations, just move a special lever and dump the coals into the ash pan.

The installation of a circulation pump allows you to increase the energy efficiency of your heating system. The device will move water through the system faster, the liquid returns to the boiler at an increased temperature. This means that it will take less time to warm it up again. The circulation pump is usually located in the return pipe before entering the boiler.

When servicing a heating unit, it is necessary to periodically check the draft in the chimney. The channel is cleaned from soot at least once a year. To prevent the formation of condensation, special sandwich pipes are used to construct the chimney or sections of the duct located outside the room are insulated.

Wall backing material

The main requirement in finishing walls, floors and ceilings is fire protection. For this purpose, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process and protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of wool is maximum.

- Basalt fireproof sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is prohibited to use polymeric materials – polypropylene, foam. For floor-standing models, special attention is paid to preparing the floor surface. It is leveled and fire-resistant material is installed. In this case, basalt wool is not recommended, as it will shrink under the weight of the boiler. The solution is to install basalt sheets.

Gas boiler in a wooden house: installation features. Installation rules. Types of equipment

If in summer few people worry about heating in the house, then in winter the problem of heat comes to the fore, otherwise it is simply impossible to live in such a room. Thanks to a variety of systems, it is possible to maintain comfort not only in the main rooms, but also in the hallway or even the basement.

In this article we will not touch upon electric and solid fuel (liquid fuel) heating systems; today our main character is a gas boiler for a wooden house.

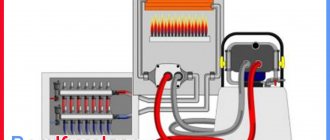

In the photo there is a wall-mounted gas boiler

With its help, you can easily maintain the desired temperature anywhere in the building. At the same time, the efficiency of the device is higher than the rest of the above equipment. The disadvantage is that permission to install it is required from various departmental organizations (see also the article “Inputting electricity into a wooden house: overhead and underground methods. Cable protection”).

Advice: in order to get the most out of a gas boiler and not waste a lot of fuel, you need to insulate the room as best as possible. One option involves replacing old windows with new plastic ones.

Installation of a gas boiler in a wooden house must be carried out in accordance with safety requirements

Material for installing a wall-mounted gas boiler

Installation of a wall-mounted gas boiler begins in the store. Of course, this is not the installation itself, but preparation for it. When purchasing or ordering a wall-mounted gas boiler, you need to find out or inspect whether the boiler is equipped with fastening elements. Usually these are hooks and power dowels. If this fastener is not included with the boiler, it must be purchased.

Boiler manufacturers complete the boiler with special installation patterns, which are used to mark and drill holes for mounting the boiler.

Note: Let me remind you that when choosing a wall-mounted gas boiler and purchasing it, you must inquire and request a certificate of conformity for the selected boiler model. Without this certificate, legalization (obtaining permission to connect) will be very problematic.

Features of installing a gas boiler for a wooden house

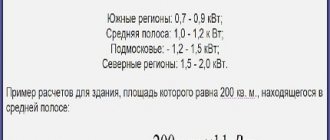

We will talk about buildings that were erected from timber or logs:

- The material has a lower thermal conductivity when compared with brick, stone or concrete. Therefore, such a house does not require high-power equipment.

- Heat exchangers can be made from:

- copper;

- become;

- cast iron

- The building's floor slabs make installation of the heating system simpler.

Tip: keep in mind that a wooden surface is very sensitive to humidity and sudden changes in temperature, so it is necessary to place heat-insulating material between the radiator and it.

- The installation of a chimney is required - a vertical pipe or a horizontal coaxial outlet is used.

Tip: if you want to save money, buy a boiler with a closed combustion chamber.

- The equipment must have an automatic protection system in case of possible gas supply shutdown.

Floor-standing gas boiler in a separate room

Installation Rules

The ease of installation of the equipment does not negate the rules for installing a gas boiler in a wooden house, which must be observed:

- It is allowed to place a gas boiler in a room with an area of 4 m² and a ceiling height of 2.5 m.

- Entrance opening – from 800 mm.

- A window of 0.3 m² is provided for every 10 m³ of room to provide natural light.

How to hang a gas boiler on a wooden wall of a house

- The room should be well ventilated and have a ventilation hole at the top.

- A gas analyzer is required.

Advice: the requirements for a gas boiler in a wooden house prohibit its installation in the basement, with the exception of special buildings.

- There must be a concrete base underneath the floor equipment.

- Electrical appliances must not be placed closer than 300 mm from the device.

- The calculation of the chimney diameter is taken according to the power of the gas device. Moreover, it must have up to 3 bends (inclusive).

- The length of the pipe between the boiler and the chimney is no more than 250 mm.

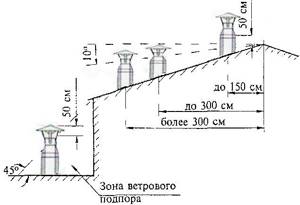

- Above the ridge of the roof, the chimney pipe should rise 500 mm or more.

Installing a gas convector in a wooden house under a window

Types of equipment

There are two main types of gas boilers that can be used in a wooden house today:

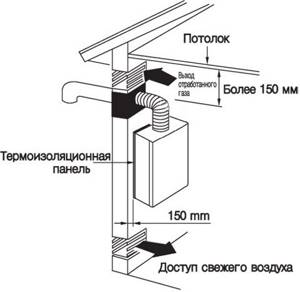

- Installation is carried out on a concrete base, which can be replaced with a metal sheet, which should protrude 300 mm around the perimeter of the device.

- When using a closed combustion chamber, a coaxial chimney is used. The hole for it can be located on the back panel of the equipment or on the top cover.

- The chimney must be placed further from the window so that exhaust gases do not enter the room.

- It is necessary to tilt the chimney pipe slightly to remove accumulated condensate from it.

- If a vertical type boiler is installed, an adapter with a height of at least 150 mm must be installed from its top cover to the chimney.

- Connecting water supply devices is possible only after installing the pipe.

You can install the equipment in individual buildings, in which case it is necessary to provide a special pocket with a recess of approximately 300 mm with a concrete screed and walls made of fireproof materials or treated with a special fire retardant compound.

- Operating a boiler of this type is more convenient and simpler.

- The equipment is light and compact in size.

- Installation of a wall-mounted gas boiler in a wooden house is carried out on a load-bearing wall.

- The mounting strip can be located at a height of 1-1.6 m from the floor.

- The installation of a coaxial chimney is carried out according to the factory diagram. The diameter of the exhaust gas exhaust pipe must match the hole on the rear wall of the heating equipment.

Connecting and installing a gas stove in a wooden house

Advice: if you can install a wall-mounted or floor-standing gas boiler yourself, which allows you to save a lot, then entrust its connection to the gas main to special gas services.

The advantage of gas heating

If you haven't yet decided what type of heating to use for your home, let's look at how you can benefit from gas:

- Cost-effective, provided proper insulation is carried out. Although the last point applies to any type of heating.

- The equipment allows you to heat almost 350 m², provided that the ceiling height does not exceed 2.5 m. Calculate its power using the formula - 1 kW can heat 10 m². Although this is somewhat approximate, the figures obtained are quite real, at least the error is not downward.

- Manufacturers offer boilers for heating only or for heating and hot water supply. The price of the latter is higher, but you can easily solve an issue that is most acute in a suburban area.

- There are two options for ignition - manual and automatic. In the first case, you need to press a button to start.

- Exhaust gases can be removed using natural draft or forced, in which case a built-in fan is installed in the system.

How to install a gas wall-mounted boiler in wooden and frame houses?

A house is a fortress for every family man, and a wooden one is also an environmentally friendly, clean, “breathing” home in which all family members will be cozy and comfortable. For many centuries, people have chosen wood as a building material for their settlements, and all because such structures are durable, thermally conductive, cozy and attractive. The house will be warm and cozy in winter, cool and fresh in summer, but without a modern heating system and properly selected and installed equipment, the owners of a wooden house will not be safe.

Let's discuss the topic of proper installation of a gas wall-mounted boiler in a wooden house.

Of course, there are room requirements for installing a gas boiler in a wooden house. They include the following:

- It is prohibited to place heating equipment in living rooms.

- Installation in the bathroom and toilet is prohibited.

- The room where the boiler is installed must have a window and an exhaust hood.

- It is mandatory to have personal protective equipment and fire extinguishing equipment, as well as smoke detectors and fire alarms.

We will not delve too deeply into all these requirements and SNIPs, but will separately consider how to safely and correctly mount a boiler on a wooden wall and remove the chimney.

As everyone probably already knows, modern gas wall-mounted boilers come with a closed or open combustion chamber, i.e. with forced removal of combustion products through a coaxial chimney or atmospheric draft boilers, through a special chimney channel. Installation in both cases has its own subtleties.

If the boiler is to be installed on a wooden wall, fire protection is usually provided. The backing on a wooden wall under a gas boiler can be done in several ways:

- A layer of basalt insulation is hung on the wall, after which it is sheathed with steel sheets.

- Special basalt and mineralite fire-retardant sheets are used. The advantage of this solution is the minimum thickness of the protective layer, while simultaneously ensuring maximum fire protection.

Installation of a mounted boiler in a wooden house without first making a protective layer is prohibited!

A coaxial system for removing combustion products can be used in wooden houses. It allows, simultaneously with the removal of gases, the intake of fresh air, which is used to support the combustion effect. This system is used in boilers with a closed combustion chamber.

It is characteristic that the installation of a coaxial chimney is possible both vertically and horizontally through the wall. If there is a need to install just such a smoke exhaust duct, then it must be laid along the shortest path from the boiler to the roof or wall.

At the point where the coaxial chimney passes through the wooden wall (Fig. 1), a hole is made for a special wall groove, which is clogged with non-combustible materials.

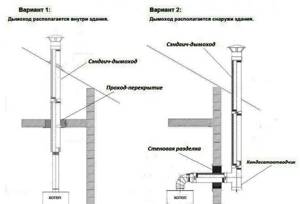

In the case where the boiler is atmospheric draft, the chimney duct is made from modern double-walled “Sandwich chimney” chimneys. Sandwich pipes are made of stainless steel. Moreover, stainless steel is used in different grades - from alloys with a small content of alloying metals to highly alloyed heat-resistant ones. The thickness of the metal can also be different - from 0.5 to 1 mm, as well as the thickness of the insulation - 30 mm, 50 mm. It is clear that the scope of application will be different, and so will the price.

There are two ways to bring the chimney outside (Fig. 2). The first is to run the pipe through the wall, and then raise it along the outer wall to the required level. The second is up, through the ceiling and roof.

If the chimney is outdoors, condensation actively forms in it due to temperature changes. Therefore, a tee with a condensate collector (glass) and a cleaning hole must be installed in the lower part of the chimney. This unit allows you to maintain the chimney without much difficulty: the glass is unscrewed and the condensate is drained. Also, soot periodically gets knocked off without any problems - you can run a special chimney brush through the cleaning hole.

The construction of a proper chimney must be carried out in compliance with certain rules. In particular, it is necessary to adhere to a certain height of the pipe protruding above the roof of the building. For example, if a modern wooden house has a flat roof, it should rise above the ceiling by more than half a meter. If the building structure has a ridge, then the chimney installed in a private house must comply with the parameters indicated in Fig. 3

Of course, in each individual case you will have to face your own specific problems and each of them will have its own constructive and correct solution. Installing a gas boiler in your wooden house is, in principle, not such a supernatural task; you just need to take into account all the nuances associated with the rules and requirements for the installation site and arrangement of the chimney. This can be done with your own hands, but it is better and more correct to turn to professionals who, firstly, can make the necessary project based on specific tasks, secondly, select the necessary and proven equipment, and thirdly, provide qualified services installation.

Installing a boiler and installing a chimney is just the beginning on the path to the final result. The result of this work for each end user is the same - an energy-efficient and efficient heating system that will never fail.

Mounting the chimney of a wall-mounted boiler

To choose the method of mounting the chimney, you need to study the type of construction of the gas boiler. If an atmospheric thermogenerator is used, then there is natural draft (without using a fan).

In the case of a closed combustion chamber, a connection is made to a coaxial chimney, and smoke will exit the equipment forcibly.

- Classic chimney. The boiler is lowered by 2 chimney diameters, as indicated in the instructions above. If the walls are not made of concrete or brick and can catch fire, then you will have to extend the thermal insulation substrate located behind the boiler by about 25 cm. Place a groove through the roofing pie and the floor slab. It is prohibited to install decorative elements on the top of the chimney that could interfere with the operation of the system and increase the risk of fire. To increase traction, it is necessary to additionally install a deflector;

- Coaxial. The pipe will exit from the boiler through the building. The length should not exceed 3 m. In this case, the fasteners must be installed in increments of 0.5 m. When installing the fixing fittings, it is necessary to take into account the joints that will be needed to install the fasteners. In the place where the pipe comes out through the roof or wall, special penetrations are installed. You can make these units yourself or buy them in a store. For homemade products, make a hole that is 2 cm larger than the pipe diameter. The coaxial chimney is mounted exactly in the center. Treat the gap with basalt reinforcement.

When installing the speaker on the wall, it is necessary to comply as much as possible with the requirements of the gas company. Connecting a wall-mounted boiler must be carried out with special care, without ignoring the standards established by PPB, SP and SNiP.

It is important to study these documents, since some nuances may vary depending on the specific place of residence, so the nuances should be clarified in your region. It is therefore advisable to have a preliminary consultation with a gas inspector.