Let's assume that you have already calculated all the communication options for your home and are inclined to use this equipment. After reading the article, you will learn what nuances you need to pay attention to when choosing a gas tank for full operation. We fill gas tanks for more than 1,500 regular customers and will gladly share our experience, tell all the secrets without pathos and advertising fluff.

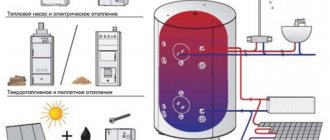

From English (eng. gaz-holder) is a special steel container designed for storing liquefied gas under pressure. The equipment is installed ten meters from your home (cottage, dacha) and, using a mini-gas pipeline, is connected to an in-house gas boiler (heating and hot water) and a kitchen stove. Once or several times a year, the device is filled from a tanker with liquefied propane-butane.

In cross-section, it resembles a transparent gas lighter. A liquid is a gas in liquefied form, and the free space above the liquid is a steam cap, the evaporated part of it, which is supplied to a gas boiler or stove. Equilibrium in the ratio of liquid and vapor cap is maintained by the pressure inside the container.

Gas holder, like a lighter in section

If the device will be operated by a legal entity, then the equipment must be registered with Rostekhnadzor. In the case of installation of containers by individuals on private property, there are no such strict registration requirements. But it is worth considering that the private owner is responsible for everything himself.

In general, the use of gas tanks is a completely common thing, which is extremely widespread in Europe, where a culture of autonomous gasification has historically developed. No one there would think of extending a gas pipeline to Alpine ski resorts or anywhere else where it is not justified for economic or environmental reasons.

What's inside the gas carrier?

A car arrives - a gas carrier . This is a specialized vehicle for refilling gas tanks .

What are its features? There is a container installed on it, in which liquefied gas is filled. This car has a capacity of 15 thousand liters. It can fill 2-3 gas tanks depending on its volume. There is a technological compartment here. It contains all the fittings, all the tools with which the gas tank is filled. These are filling taps, drain taps, and control devices. There is a counter here, a control unit, which, by the way, not every gas carrier uses, but it’s definitely worth paying attention to. Because this unit allows you to remotely monitor how much gas is being drained into your gas tank. This is all written in memory and remains on our computer. You can also connect to this system and already see how much gas has been drained to you and how much gas is in your gas holder. Also an important point.

How to save on gas station

Consumption and number of refills throughout the year greatly depend on the size of the house and its level of thermal insulation. Our average figures are a house with an area of 200 square meters. m. and the most “popular” volume for it is 4500 liters. With such initial data and permanent residence in the climatic zone of the Central Federal District, you will need 2 refuelings per year: one at the beginning of the season - in the fall, the second at the end - in the spring.

Gas tank filling machine

The nuance is that the price of gas fluctuates throughout the year with an amplitude of 25-30%. The maximum occurs in autumn, the minimum in spring. In order to always refuel at the lowest price, we recommend buying a gas tank with a larger capacity - 6000 liters or more. Which container is best to choose for a country house, read the article: volume of a gas tank for a country house. The increased volume makes it possible to adjust your own consumption and wait for a period of low prices. The savings on refilling will very quickly pay for the increase in the cost of the device due to the larger capacity, and then very decent savings will follow.

What should the pressure be?

Let's consider pressure sensors . There's a ton of stuff here, a ton of all kinds of taps. These are the ones you need to pay attention to when a gas carrier arrives. This is very important so that you can understand what quality of gas has arrived to you. Good quality propane gas - it has a higher pressure than butane. And for gas tanks, it is propane gas that is required, so that the gas contains as much propane as possible.

In winter you need to make sure that the pressure is not lower than 5, and in summer it should be no lower than 8, or even 9 atmospheres. This means that you have received high-quality gas. This is an indirect indicator, but a very important one. Few people know about this. This is a moment that we even define for ourselves. If we arrived at some wholesale base and filled up with low-quality gas, the pressure will be very low. This will be a signal for us that we need to check. Something is either wrong with the system, or we were simply filled with low-quality gas. Then we start using a density meter, with which we check the quality of the gas. Thus, we understand that we need to change it, or we agree that everything is fine with us and we are already delivering this gas to the customer.

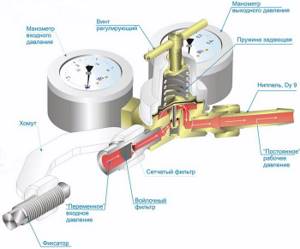

Operating principle of the stabilization device

Modern pressure reducers for gas tanks operate on the reverse action principle. The gas coming from the inlet rod tends to close the pressure reducing valve.

The adjusting screw compresses the main spring and when air leaves the working chamber, the flexible membrane pushes the transfer disk with the pin up. At this moment, the pin compresses the return spring, moving the reducing valve away from the seat, and the gas enters the working chamber.

Two-stage gearboxes are less susceptible to freezing, so such devices must be installed on gas tanks in regions where extremely low air temperatures are observed

After the substance moves into the low-pressure chamber, gas exits into the system. As a result, the spring relaxes, the transfer disk and pin lift the valve, gas from the upper chamber enters the low pressure chamber, and the process repeats.

When the gas release decreases, the pressure in the chamber will increase, the spring will take the “closed” position, the valve will lower into the seat, and the gas supply to the reducer and low pressure chamber will stop.

To stabilize the gas pressure in the gas tank, two-stage reducers are used. The fuel in such regulators, before entering the outlet fitting, goes through two stages of reduction.

To increase the life of the gearbox, it is necessary to minimize the contact of the membrane and other elements with moisture. To do this, at the installation stage, decorative or standard protection is installed above the tank

Two stages of the reducer provide maximum stability of the output pressure, so they are safer during operation.

In addition, two-stage devices are resistant to freezing, so they provide a continuous supply of gas in summer and winter. If the gearbox is still frozen, we recommend reading our other article, where we described in detail how to fix this problem. Read on for more details.

Tank purging and safety

Now the refueling driver directly connects the pistol to the gas tank in order to refuel it. A very important point. We pay close attention to this. So that around a radius of preferably 30-50 meters, no non-welding work is carried out, no cutting of metal, so that there are no sparks. Nobody smoked. For safety reasons, it is even forbidden to use mobile phones. Because when filling gas the tank is purged. That is, the gas comes out together with the air. Accordingly, if it accumulates, there is a risk and possibility of fire. By the way, regarding safety precautions, the driver must be dressed in overalls. His legs and arms should be protected as much as possible. Because the gas is at a negative temperature and it can burn the skin quite strongly.

If you are near the gas tank while refueling, you should also be as protected as possible from possible skin injuries.

A noise is heard in the gas tank - this is not yet refueling, but the driver opened the tap so that the excess air pressure that had accumulated there came out. When filling a gas tank, the gas that fills the barrel simultaneously displaces air from there so that the container is completely filled with gas. Because if there is air left in it, it will affect the operation of the boiler. There will be interruptions. Because air doesn't burn, but gas does. We need completely clean gas there. Therefore, to do this, you need to bleed all the air out of the barrel.

We choose a gas tank. Important nuances

Nowadays there are imported and Russian-made devices on the market. Foreign manufacturers boast special grades of durable steel, which make the walls thinner and the equipment itself lighter. Russian analogues, on the contrary, are made of thicker metal with a decent margin of safety. In essence, this device is an ordinary barrel without any special features and, in our subjective opinion, it is better to buy it with thicker walls. Read more in the article: which gas tank is better: information for the curious.

You can also watch a video about installing and connecting a gas tank:

A fundamental point for those who want to save money. Do not under any circumstances buy a used container, it is a time bomb. Gazoem “with history”, in 99% of cases, lay for 20-25 years in the ground, somewhere in Poland or the Czech Republic. They took it out, removed the outer protective layer of tar, painted it and are trying to sell it at a reasonable price. The problem is that propane and butane contain a small amount of moisture, so the inner surface of the walls is susceptible to corrosion and gradually becomes “loose”. There have been cases when, after filling such gas reservoirs, a characteristic odor appeared in the area. Correcting the situation along with pumping and degassing will cost a lot of money.

Do not buy used gas tanks

Every spring, many owners of underground gas tanks call and complain about gas supply interruptions. This occurs due to the flooding of the tank reducer by seasonally high groundwater levels. Therefore, it is better to buy equipment with a high neck, in which the reduction group (reducer, filling valve, etc.) will always be located above the flood level.

Don't forget about the additional metering device

Let's go back to the car. Let us pay attention to a very important point when receiving gas, when draining it into the gas tank. The draining process began and gas began to flow through the meter. The meter spins in the same way as at any gas station and begins to show how many liters of gas it drains. On ordinary machines, most machines that exist today, this counter is in one copy, as a rule, it is an American LPM counter. They are quite good, they give clear readings. But on our machines, and I recommend that you order machines from such suppliers, this meter is duplicated by an additional metering device. In the form of electronic control. The readings are reflected on the meter and duplicated on this electronic controller. This data is transmitted to the dispatcher in the office. He remotely sees how much gas is currently being poured into your gas tank and, in fact, when receiving gas, you may not even be on the site. You can also view these readings remotely. This is a great convenience and great trust between us, as the company in charge, and our customers.

Propane is out, butane remains

Comment on the situation

The problem is the uneven consumption of the mixture components. At temperatures below -0.5°C, propane evaporates, and butane remains in the liquid phase. If you use the mixture year-round, then over the summer the ratio is restored. If you use it periodically and only in cold weather, it will start to jam.

Reasons for increasing butane content

Propane burns first due to uneven use of equipment. If you turn on the heating only in cold weather, then in a few years all the propane will be used up. Although the level gauge can show 20-30% of the volume of the liquid phase. In the example from the forum - 51-52%.

Answer from engineer Evgeny Kalinin

It’s unclear the quality of the gas—what the percentage was when filling it up. In general, the cause of the problem is the slowdown in LPG vaporization. Butane evaporates slowly, so the pressure is enough for several hours of operation.

Do not preserve the filled container for more than 2 years. The gas does not mix and stratifies. With seasonal use, one barrel can be used for 2-2.5 years. Depends on gas quality, tank and installation.

How to restore boiler operation when only butane remains inside

Order refueling with a winter mixture containing at least 75% propane - this is the only way to quickly increase the evaporation rate and pressure.

Install an evaporator to force the butane into the vapor phase. Then the container will simply become a fuel storage facility.

A small 1 cubic meter gas holder can be wrapped with an energy-saving cable to avoid getting tangled.

How to prevent rising butane levels

It will not be possible to completely get rid of the uneven consumption of LPG components. To slow down the booting process, refuel with fuel with a higher propane content. Especially if the heating system is used periodically and only in cold weather.

Let's sum it up

In conclusion, we will once again emphasize the main points that you need to pay attention to.

- Be sure to check the data on the meter that is displayed when refueling the car.

- Be sure to check this data with the level gauge that you have installed on the gas tank. They must match. Of course, discrepancies are possible. But they should not be global so that no one can deceive you.

- Be sure to choose a reliable, trusted supplier who has come to you more than once, whom you trust, and with whom you have already established a good relationship.

It would seem that everything is simple - compare the meter readings, compare the gas tank readings and everything is fine. But in life, as a rule, everything happens much more complicated, and there are a lot of emergency situations. And we will try to sort them out with you.