What are the benefits of installing mud traps for a heating system?

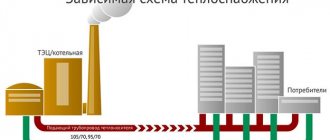

There are no questions about the need to install dirt filters for water in centralized heating systems. Where the coolant is periodically drained and the system is refilled, it is impossible to argue with the necessity of this element in the system - there will always be dirt and foreign impurities.

A disdainful attitude towards mud collectors begins with the independent design of small autonomous systems. For example, heating systems of a private house. It just seems that in a small closed circuit there is nowhere for foreign impurities in the coolant to come from.

Dirt filter with tap.

Whatever type of coolant is used, and no matter what initial cleaning it undergoes, it will still be based on water. Water, which begins to interact with the metal components of the system, and there is metal in any system. As a result of this interaction, rust particles are formed that circulate in the system. In certain areas of the system (irregularities inside the pipes, welding sagging, sharp turns, narrowed passages, etc.) these particles accumulate, impeding the movement of the coolant.

Mechanical coarse water filter.

Since the intensity of circulation of the coolant decreases, in order to achieve the desired temperature parameters in the room, its temperature must be increased. This increases the load on the boiler and all other elements of the system, which does not add reliability, economy and efficiency to them. Proper installation of mud filters in the system eliminates most of these problems or, at a minimum, delays the time of their occurrence.

Why do you need a mud collector?

Due to the fact that there are foreign fractions in the coolant, they accumulate at the pipe joints. Therefore, the diameter of the pipes inside decreases. Such fractions have a detrimental effect on the cavities of the heating circuit elements. They can clog the cavities of the heat exchanger, circulation pump and other elements.

Due to such factors, the efficiency of the heating boiler is significantly reduced. And the risk of breakdowns and system failures also increases. The coolant takes longer to heat up, and fuel consumption increases. Since to quickly warm up the room it is necessary to increase the power of the heating boiler.

It is precisely because of such factors that mud collectors need to be used. After all, they catch persistent mechanical particles such as scale or rust. And they cause considerable damage to fittings in the pipeline and heating equipment.

Peculiarities

A mud filter is a device for filtering and purifying water inside heating systems. Such a filter prevents the formation of deposits on the internal walls; it filters out foreign objects in the pipeline. This device has a number of modifications, each of which has its own characteristic differences. They comply with GOST standards; they are selected taking into account the cross-sectional diameter of the pipes. In general, the purpose of the devices is to clean the coolant before it enters the system itself.

The devices operate on the principle of a colander: water flows through a pipe into the mud pan, at the bottom of which suspensions settle. The purified liquid continues to move through the outlet pipe and enters the heating system. By changing the direction of water flow in the water supply, the mud filter divides the water into clean liquid and dirt, which settles in a special filter container.

This device is functional, you can use it to do the following:

- increase the efficiency of the heating system;

- equalize the thermal output of batteries;

- extend the service life of each element of the heating system;

- reduce home heating costs;

- reduce the risk of emergency situations and leaks;

- Eliminate the need for manual flushing of the system.

Such products protect the main components of the system from dirt and clogging of working channels. They remove dirt from contaminating pipe channels, taps, air valves, and expansion tank pipes. This ensures an increase in high-quality heating of the coolant several times. During normal operation, the water condition will be acceptable for circulation in the system without deposition of lime and alkaline salts. The heat supply inside the pipes will be correct, without wasting energy.

The mud trap is a tool for improving the operation of the system, a unit for expanding the pipeline system by changing the direction of the water flow. Typically, pressure gauges are installed near it, indicating the degree of hydraulic resistance. They are installed on both sides of the filter. A distinctive feature of the installation is the fact that the sump must be directed towards the coolant flow. For ease of installation, manufacturers make an arrow on the body indicating the direction of movement.

Over time, large debris and dirt will accumulate in the sump and will need to be removed. To service the mud pan, first shut off the system, then unscrew the nut located at the bottom of the body. After this, take out a special glass with suspensions. The container is emptied, then put in place and the nut is screwed on. The location of the sump determines the frequency of its cleaning. For example, if a buyer buys a product with a vertical glass, it will have to be cleaned more often.

The principle of operation of the mud collector is extremely simple. This process is cyclical and is repeated many times. However, choosing a product is impossible without at least a superficial understanding of the features of its varieties. After all, not every type of device is suitable in a particular case. And it’s not even a matter of price, but of the different cleaning capabilities of individual modifications.

Classification of mud collectors by particle type

Mud collectors are classified according to the type of particle separation:

Septic tanks

The operating principle of these devices is based on gravitational forces. With a sharp increase and decrease in the flow rate of the working medium, solid particles settle under the influence of gravity. In addition to gravitational forces, the flow can be affected by centrifugal forces due to a sharp change in the direction of the working medium. This helps remove inert heavy contaminants.

Mud settling tanks are most often used in industrial enterprises. The cylindrical cavity has several jumpers to change the movement of the medium flow as it passes through the built-in filter. In this case, suspended particles settle to the bottom and are then cleaned.

Mesh

The most common type of mud traps, consisting of a lid, needle valve, float, air separator, mesh, drain valve, etc. There are coarse and fine filters. In the first case, contaminants ranging in size from 5 to 300 microns are removed, in the second - particles of smaller fractions (up to 5 microns).

Mud collectors with fine cleaning are used in enterprises where additional water purification is required - in household water supply systems, etc. For heating, coarse cleaning is sufficient. The needle valve as part of the mesh sump helps to avoid accidents when the system is contaminated with gas.

Magnetic

Mud filters with a magnet acting as the main filter element. It helps to clean the medium flow from metal suspensions, helps reduce the accumulation of scale on the walls of pipes, and prevents the formation of rust. In this case, the flow of working fluid does not slow down and the pressure does not change. This allows magnetic mudguards to be installed on the suction parts of the pump.

Installation and maintenance of main filters

Installing a carbon filter for hot water or any other type of treatment plant is quite simple

It is only important to follow the step-by-step instructions and be consistent

How to install a filter: step-by-step instructions

The installation process of the main filter consists of the following steps:

- First, you need to stop the water supply to the house, and also drain the remaining liquid from the taps in the kitchen or bathroom. This will get rid of any remaining liquid. However, before performing installation work, you need to install a basin under the insertion point for water that may leak.

- You need to put marks on the wall to fix the filtration system. The fastening must be rigid, since any vibrations can damage the system.

- Using the marks, holes are made into which the plastic pieces of dowels will be placed.

- Next, the filter is connected to the pipes using couplings. To ensure the tightness of the joints, FUM tape is used.

- The device is fixed to the wall using self-tapping screws.

- To assess the quality of installation, you need to restore the water supply and open any tap for a few minutes. During this period of time, the cartridge will be cleaned and the system will be cleared of air.

- From the moment the installation work is completed and the filters are started for the first time, the system’s service life begins to count.

How to change cartridges

Metal water filters are equipped with special removable cartridges. During operation, they may fail and need to be replaced. It is not difficult to carry out such a procedure with your own hands. To do this, you should follow these instructions:

- We turn off the tap at the entrance to the house.

- Relieve the pressure in the system.

- To prevent neighbors from flooding, it is better to place a basin under the flask.

- Using the key from the basic package, you need to unscrew the flask.

- Next, remove the filter part, wash the mesh and attach a new cartridge. The flask is also cleaned of impurities.

- After installing the flask in its original place, you need to make sure that there are no leaks.

Proper and timely replacement of working parts will ensure complete cleanliness of the liquid and eliminate the problem of pressure surges when cartridges become clogged.

How to replace the filler

And although the filling filter with filler has a simple structure, replacing this substance can be difficult. To avoid mistakes, you should follow these instructions:

- First you need to disassemble the filtration column and remove the control valve.

- Next, you should unload the used media and clean the equipment and add new filter media.

- At the next stage, the system is assembled and connected to the water supply.

Installation of a sump for a heating system

In order to install a magnetic filter for heating or a filter of any other type, you should familiarize yourself with the following recommendations that can simplify the entire work process:

- Even before installation begins, it is necessary to carefully prepare the system pipes, cleaning them from rust and other harmful particles.

- When deciding which type of sump design to use for a particular heating circuit, you need to be guided solely by its operational characteristics, in particular, the conditions under which the equipment will be used - operating pressure, temperature readings, etc.

- It is better to choose a location for installing the sump tank where access to the device will be as convenient as possible, taking into account that the filter should be mounted in the area in front of the circulation pump.

- One of the prerequisites for installation is that the cross-section of the filter opening must be identical to the cross-section of the pipe. This measure will ensure the strength of the connection and will prevent the mechanism from subsequently moving aside.

Installation rules

All filters have a working fluid direction arrow on the transparent panel. Installation of mud traps for heating occurs subject to strict adherence to this instruction. The best options for the location of these devices are:

- metering devices;

- circulation pumps;

- near the regulatory structures of the system.

When installed horizontally, the spout of the device is placed at the bottom, and when installed vertically, on the side. Otherwise, extraneous fractions will not be removed from the system. It is recommended to install check valves and shut-off valves in front of the dirt trap, and pressure reducing valves behind them to control pressure indicators.

Cleaning the cartridge filter

Such systems, often installed in country houses, are cleaned in a different way. You will need a filter key, a pan or bucket, a replacement cartridge or a container where you can clean the old one.

First, turn off the valve and make sure that there is no water left in the tap. Then place a bucket underneath: excess liquid from the flask will be drained there. Using a special wrench, you need to unscrew the nut and remove the flask. After this, you can either install a new cartridge, or thoroughly rinse and return the old one to its original place. Then the flask is returned to its place, the nut is screwed back in, and the water is turned on.

Not any cartridge can be reused: this option is only for wound ones. You can wash such a product using strong water pressure (it is recommended to use a hose for this).

How does a mechanical cleaning filter work?

Mechanical cleaning filter device

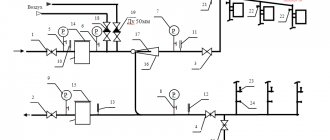

To understand how to install the filter correctly, let’s take a closer look at what parts it consists of. A detailed diagram of the heating system sump device can be seen in the figure. The body is usually made of brass. Large diameter industrial models may use cast iron. The working part is a fine-mesh steel mesh. As a rule, it can be removed for washing or replacement. The frequency of cleaning the heating system's mud traps depends on various parameters: water hardness in your region, pressure in the pipeline, and the total volume of coolant passing through the filter. There is also a dependence on the materials from which the pipes and components are made. Materials with different corrosion resistance will pollute the coolant at different rates. You can set the required frequency experimentally. The figure shows methods for installing a filter in a pipe with explanations for each of the possible options. As we can see, both with vertical and horizontal insertion, the glass for depositing filtered particles should be at the bottom.

Methods for installing a filter in the system

In conclusion, it should be added that it is often advisable to use a combination of filters to increase the service life of the system. For example, a mud trap for heating and a magnetic filter for a boiler. Or a system of mesh cleaners installed in series.

Installing the pump

Position relative to the horizon

How to install a heating pump correctly in terms of its service life? Surely there are factors that can lead to accelerated wear of the mechanics.

The instructions are related to the operating features of the mechanical part of the device. The design of a heating pump, used to create individual heating systems of moderate power, involves continuous cooling of the rotor and shaft with bearings by circulating coolant.

To prevent air locks from leaving the bearings without lubrication and cooling, the motor shaft must be positioned strictly horizontally.

Correct and incorrect pump positions.

Water filtration

It is highly advisable to install a sump tank in front of the pump. Its function is to filter out the inevitable sand, scale and other abrasive particles that destroy the impeller and bearings of the circulation pump.

Since the diameter of the pump insert is usually small, an ordinary coarse filter is quite suitable. The barrel intended for collecting suspended matter should be directed downwards - this way it will not interfere with the circulation of water, even when it is already partially filled.

Attention: on most filters, an arrow indicates the recommended direction of water circulation when installing it. Yes, the filter will perform its function even if installed incorrectly; however, you will have to clean it much more often, and it will be much more difficult to remove ALL the sediment.

Pump location in the circuit

Where, in what part of the circuit is it recommended to install a heating pump?

Formally, modern pumps work equally well on both supply and return in any part of the heating circuit. However:

- The higher the temperature of the coolant, the lower the service life of the bearings and all plastic parts of the device. From this point of view, it is still necessary to embed it on the return pipeline, directly in front of the boiler.

- It is recommended to install the expansion tank in a section of the circuit with the coolant flow as close to laminar as possible. After the pump, the flow will inevitably be turbulent. Hence the second amendment: the circulation pump cuts in before the boiler and after the expansion tank.

The optimal condition for an expansion tank is a water flow with a minimum of turbulence. Before the pump, the flow in the circuit is almost laminar.

Bypass

Remember our thoughts that it is highly desirable for the heating to work even when the electricity is turned off? Albeit with less efficiency?

How to install a heating pump with your own hands so that it does not interfere with natural circulation?

Let's think out loud for a bit. The gravity system is characterized, first of all, by a minimal difference between supply and return. Therefore, for an acceptable circulation rate, a minimum hydraulic resistance of the circuit is required.

What increases it?

- Rotations and bends of the contour.

- ANY shut-off valves.

By the way: it is from this point of view that only modern ball valves should be used in any autonomous heating system. Unlike their screw counterparts, they offer minimal resistance to water flow when open. To understand why this is so, take a look at an open valve of this type.

When the valve is open, the lumen in it does not differ from the lumen of the pipe. In addition, there are no bends and turns where the difference is lost.

- Reducing the pipe diameter.

What are filters for heating systems - types

The following types of heating filters are distinguished:

- Rough or pre-cleaning. They must be installed at the stage of connecting to the central water supply (if such a possibility exists). The most reliable model is a sedimentation tank with a flask for the accumulation of pollutants.

- Fine cleaning. Detains contaminants up to 100 microns in size.

- Magnetic devices. They attract metallized components - chips, rust, etc.

Let's take a closer look at each type.

Coarse filters are designed to retain large contaminants and can be installed simultaneously in several areas of the system. Presented in the following modifications:

Mud collector: connects to the central heating system, at branch points (can be flanged, welded, threaded), Sump filter: a more modern model, dirt is retained in a special flask made of heat-resistant plastic (due to the transparency of the flask, you can control its filling level). Fine cleaning – installed as an addition to coarse cleaning devices. The main impact in such devices is taken by the square or cylindrical cassettes installed inside

Such devices can be attached to the wall, which is especially important for plastic pipes. Magnetic filters - consist of two magnets with opposite poles. Metal waste entering a magnetic field is attracted and retained by such a device

The design can also be equipped with a dirt filter. Magnetic models can be either removable and quite easily installed on the pipe, or non-removable. Recommended as an additional cleaning device.

Many people ask the question: is it worth spending money on purchasing all types of filters? Perhaps only a coarse cleaning device will be enough? Experts assure that the most effective protection will be provided by all types of structures that will retain as much possible contamination and impurities as possible. The coarse filter can only cope with large particles, and this is not enough for the heating system to fully operate for a long time.

How often does it need to be cleaned?

Due to water purification and retention of various debris, which does not disappear over time, it begins to accumulate. For this reason, over time, the water filter installed on the pipe becomes clogged. This leads to a decrease in water pressure, and over time, its complete absence. When such situations occur, it is necessary to clean the internal structural elements, for which the device should be removed, disassembled and washed.

Worth knowing! When the filter is sealed along with the water meter, you need to call a technician from the management company who will remove the seals. Once cleaning is complete, it is recommended to install a non-return valve, allowing cleaning to be carried out without the need to call a specialist further.

Recommendations for pump installation procedure

This work should be done in the so-called “off-season”. But if there is a need to carry out the installation during the heating season, the boiler needs to be “turned off” and wait until the temperature of the coolant drops - these are basic things that do not need additional comments.

- If it is necessary to install a bypass, it is better to assemble it separately, installing all the fittings and the circulation pump. All that remains is to make an insert into the pipe.

- The next stage is bleeding the air while simultaneously monitoring the system to detect leaks.

After this, you can safely switch the circuit to work with a pump.

Useful tips

Circulation pumps are divided into 2 groups, according to the specific location of the rotor - “wet” and “dry”. What is the difference? Without going into the specifics of engineering solutions, it is enough to just note the pros and cons of each modification.

With a “dry” rotor. Higher efficiency. But there are also disadvantages - increased “noise”, the need for regular maintenance (primarily lubrication of seals) and special requirements for operating conditions. Such circulation pumps must be installed in separate, absolutely clean rooms. The explanation is simple - the slightest dust leads to a decrease in their efficiency or breakdown.

Recommendation - it is advisable to purchase a “dry” pump if there is no analogue in the boiler itself, and the product is the only device that ensures water circulation through the pipes of the heating system.

With a “wet” rotor. As a rule, these pumps are installed more often. The fact is that all modern household heating boilers are initially equipped with such a device (located under the casing of the unit), and the newly installed one serves only as an additional element that ensures better coolant circulation. For example, when choosing the wrong heat generator model, when increasing the length of the heating circuit, when installing radiators not provided for in the primary circuit.

The disadvantage of such a pump is low efficiency. But taking into account that it is not the only one in the system, this drawback is leveled out, since it does not particularly affect the heating efficiency. An additional advantage is that no maintenance is required. Such pumps function properly until their service life is completely exhausted, provided that the rules for their installation are followed.

Recommendation - if your household boiler already has its own pump, then you can safely choose a product with a “wet” rotor.

Why is it worth installing a filter on your heating system?

Many users may quite logically be interested in the question of whether it is necessary to install filters for heating systems? It is worth noting that even without organizing cleaning, the equipment can function normally, another question is how long?

First of all, such an installation is necessary to ensure reliable and uninterrupted operation of heating equipment, eliminating emergency situations and failures.

The price of heating filters is not so high; its timely purchase and installation will cost much less than later repair or replacement of heating elements. Not to mention the fact that an accident in the heating system will lead to such unpleasant consequences as cold and discomfort in the house (after all, it is during the cold season that the thermal regime must be maintained).

The advantages of the installation include:

- reliable protection of the system from blockages;

- it is not necessary to change the water (coolant) so often;

- the service life of heating equipment is extended;

- cost savings;

- confidence in the reliability and uninterrupted operation of the system.

Principle of operation

The principle of operation of mud collectors of any type is carried out according to an extremely simple scheme:

- The coolant enters the pipe and is then directed into the housing. Dirt particles settle to the bottom.

Then water from the internal cavity of the mud tank enters the filter installed in the outlet pipe.

After which the purified coolant enters the pipelines of the heating system.

Cleaning from dirt particles occurs by removing the glass from the outlet pipe. The lower part of the mud collector body must be periodically cleaned of accumulated dirt. The mud filter is connected to pipelines using both threads and flanges.

Magnetic type mud collectors are considered an excellent invention. Rust is attracted to the magnet, which in no way affects the intensity of water flow in the heating system. Particles caught by a magnet accumulate in places specially designed for this purpose.

Due to the fact that mud collectors for heating systems do not change pressure, they can be used on the suction line of high-power pumping equipment. In this case, the magnet looks like a thin cylinder with a diameter of approximately 40 mm.

Some consumers doubt that installing a mud trap on the heating system pipeline is so important. For those who believe that the system will function perfectly without this device, it is worth saying that, of course, you can do without it. But at the same time, the operational life of the system will be significantly reduced due to contamination and other factors associated with this. The efficiency of the heating system will also decrease.

The advantages of this product are undeniable, especially when the operation of the heating system requires frequent cleaning of boilers and pipelines. Mud collectors also come to the rescue in winter, when heating appliances are not yet warm enough.

So, the advantages of a mud trap for heating systems are obvious. Moreover, its cost is relatively low. So don’t think too much about whether to install a filter for your heating system. Of course, purchasing this product is much more profitable than fixing any breakdown or replacing system pipelines.

It is also worth considering the fact that, in addition to financial costs, interruptions in the operation of the heating system can bring a lot of worries.

With a mud collector, the system will function reliably, and most importantly, the likelihood of emergency situations will decrease.

1. 2. 3. 4. 5.

Of particular importance in installing heat supply in a house is an element such as a filter for the heating system. The scope of application of this equipment is those heating systems where the main heat carrier is hot water. Thanks to such a device, the entire heating circuit will function reliably and safely, since numerous harmful substances such as debris particles and various impurities in the coolant can cause significant harm to the entire system.

Thus, a dirt filter for heating retains all these substances, preventing them from entering the most important elements of the heating circuit - the heating boiler and circulation pump. Damage to them can cause the entire system to fail, and repairs are usually quite expensive. Therefore, it is very important that the mud pan for the heating system was installed correctly, and for this, first of all, you should study all its technical and operational characteristics, which will be discussed further.

Reticulate

The mesh device is a housing with a mesh filter inside. The most popular option looks like a piece of pipe with a diagonal “spout” (bend), at the end of which there is a screw-off plug. Water, passing through the mesh, leaves suspended matter in it and then goes into the purified system.

From time to time you have to unscrew the plug and remove the filter mesh for washing. Then everything is put back in place, and the device itself does not need to be removed from the pipe. This is the so-called flushing threaded mud sump, but there are many more different types.

According to the type of self-cleaning, the mesh filter can be:

- non-flush - rinsing is carried out after removing the device and disassembling it;

- flushing - to clean, just unscrew the plug and remove the mesh;

- self-flushing - dirt is removed from the mesh by a water flow from the opening of a special drain valve.

Depending on the mounting method, coarse filters differ in:

- welded;

- threaded;

- flanged.

Most heating models have an additional mesh to separate air from the water flow. When it accumulates excessively at the top of the mud trap, the float is activated, and the needle valve allows the gas to exit the device.

The effectiveness of the mesh option directly depends on the smoothness of the increase in hydraulic resistance in the system, both before and after it. Constant changes in pressure in the pipes can cause dirt particles to be forced through the mesh.

You can track the degree of contamination of the mesh by constantly removing it and visually checking it. Or install pressure gauges on both sides of the sump tank and use their readings to monitor how dirty the filter is. There are also variations with a glass bulb for visual inspection.

Universal filter mesh

The simplest mesh filter for heating. It consists of a body (metal) and a cylindrical mesh located inside the flask. The housing is closed with a plug or tap, depending on the type of filter. Connection system - flange. There are washable and non-washable filters. Non-flush ones must be replaced at the end of their service life. The washers last a long time thanks to cleaning. It is necessary to stop the water circulation, dismantle the cover, remove and wash the mesh, and install it. In addition to its relatively low price, the mesh is attractive due to its simple design, easy maintenance and cheap components. This filter is installed in front of the fine cleaning system. This is the penultimate level of protection. Serves to purify water from scale or solid inclusions. Pipe fittings or pumps damaged by scale will cost tens of times more than a cheap filter. The filter does not take up much space.

Main types of filters and their design

Today, several designs of mud filters for heating systems have been developed. The principle of operation is similar for all - filtration of a coolant liquid, extraction of solid insoluble inclusions and their accumulation in a filter element or settling tank. Depending on the type of system, there are mud filters for industrial systems, and there are those that are used in individual heating installations, for example, in apartments or private houses.

Classification according to installation and cleaning method

Mud traps for heating systems are most often classified according to the method of installation in the system:

- On a threaded connection;

- Installed using flanges;

- Devices that require welding for installation;

New devices for plastic heating pipes are installed by soldering, so they can conditionally be classified as welded, although today they can be called a separate type of classification.

Classification according to the degree of purification divides filters into coarse filters and fine filters. The former are capable of capturing only large particles, but fine filters are capable of sifting out particles of several microns.

Classification by method of service

There is also a classification according to the method of maintenance, in other words, because the contents of the filter elements are cleaned:

- Self-cleaning;

- Flushing;

- Non-flush;

The former are cleaned by washing the mesh when opening the valve on the filter housing. All contents are simply discharged out through the valve. In washable filters, after removing the lid or flask, the filter element is removed and cleaned first with a brush and then washed with a stream of water. Non-flush ones require complete removal from the system and maintenance in workshops or replacement with a new mud collector.

For a specific heating system, it is also important how the coolant is cleaned. The simplest and most common are mesh filters.

In the body of the mud tank, the coolant passes through a stainless steel mesh and insoluble particles are retained on the metal. To clean the filter itself, rinsing is done by opening the valve on the body or removing the mesh from the filter bowl

The simplest and most common are mesh filters. In the body of the mud tank, the coolant passes through a stainless steel mesh and insoluble particles are retained on the metal. To clean the filter itself, washing is done by opening the valve on the body or removing the mesh from the filter bowl.

Strain filters are installed both in small installations and in industrial heating plants. The advantage of this type of device is its reliability and simplicity of design.

In addition to the usual mesh filter, mesh filters with self-cleaning and with the additional function of an air vent have recently begun to be used. In addition to the coarse filter, a separator filter made of a fine mesh network is installed in the housing, which ensures the separation of gas particles and removes them to the air vent. The operating efficiency of this type of device largely depends on the pressure in the line - the higher the pressure, the more effective the process of cleaning and degassing the coolant.

Magnetic filters are similar in design to mesh filters, the only difference being that magnets are installed around the mesh in the housing, which attract metal particles and rust.

Another type of device provides cleaning of the coolant using gravity. The filter housing is a large-diameter container in which pipes for inlet and outlet of coolant are installed at different heights. When entering a large-diameter settling filter, the liquid changes direction of movement, which results in the formation of numerous flows and turbulences. Heavy particles break off and settle to the bottom of the filter. Such installations are most often used in industrial boiler houses and heating plants.

Types of devices

Based on the degree of purification, mud collectors are classified into several types.

Rough cleaning. What is a sediment filter?

The coarse cleaning device is an angular mesh filter with a mesh of up to 300 µm-microns. The device is also equipped with a drain in which dirt accumulates. This product is designed to clean coolant from large and small fractions.

Design

Depending on the design, there are several types of coarse mud collectors:

- According to the method of connecting the device to the pipe. There are flanged, welded and threaded devices.

- By location on the structure. This is a horizontal and vertical device.

The mudguard is made of brass, steel and plastic. The first option will withstand elevated temperatures. A steel device wears out quickly. The plastic product can only withstand relatively low temperatures up to +90 degrees Celsius.

One type of coarse mud filter is a sediment filter. This is an improved design equipped with a flask. It is located at the bottom of the device. When a large amount of dirt accumulates on the mesh, it falls down under gravity. Thanks to this, such debris accumulates in the flask and does not end up in the radiators.

Photo 1. Coarse settling filter for heating systems. Contaminants from the pipes fall into a special flask.

The design is also improved with a separator. Air accumulates in it and enters the circuit. When its level reaches the limit, a valve opens on top of the device. After this, the air leaves the system, which prevents the formation of air locks.

Operating principle

There is a mesh inside the filter. This element blocks the inlet through which the coolant moves. During the passage of liquid through the mud filter, medium and large sized fractions are cut off. After this they move to the outlet. Thanks to this, relatively clean coolant flows to the radiators.

Advantages

Improved designs have the following advantages:

- Thanks to the flask, there is no need to remove the device to assess its degree of fullness. The assessment is carried out visually.

- A tap is fixed at the bottom of the device. Dirty water is drained through it.

- The filter removes air from the system, which prevents rust from occurring. This extends the life of the circuit.

Installation location and features

The installation location of the device depends on which heating system it is used for. For autonomous circuits, it is mounted at branch points, on the return before connecting to the boiler and on the bypasses.

Correct operation of the device is guaranteed by correct installation. Before installing any device, the circuit is cleaned of dirt and rust.

There are special symbols on the mud pan that indicate the movement of liquid through the pipes.

The product should only be installed in accordance with this instruction.

If the mechanism is not fixed correctly, hydraulic resistance will arise inside the structure.

Attention! The mudguard provides the circular pump with protection against debris from penetrating the blades. If you refuse to use it or install it incorrectly, the likelihood of engine and impeller failure will increase.

Owners of private houses who live in them all year round know that installing and maintaining a heating system is not a cheap pleasure, so it is important to pay attention to protecting complex equipment from various hazards and contaminants. For this purpose, special filter elements are used.

In order for the heating system in the house to work properly for many years, it is necessary to install special filters that will protect pipes and radiators from clogging, rust, scale, and pollutants. Magnetic, mud, settling tanks and other types of structures will extend the life of expensive equipment and allow you not to worry about premature breakdowns.

Installation of a sump for a heating system

In order to install a magnetic filter for heating or a filter of any other type, you should familiarize yourself with the following recommendations that can simplify the entire work process:

- Even before installation begins, it is necessary to carefully prepare the system pipes, cleaning them from rust and other harmful particles.

- When deciding which type of sump design to use for a particular heating circuit, you need to be guided solely by its operational characteristics, in particular, the conditions under which the equipment will be used - operating pressure, temperature readings, etc.

- It is better to choose a location for installing the sump tank where access to the device will be as convenient as possible, taking into account that the filter should be mounted in the area in front of the circulation pump.

- One of the prerequisites for installation is that the cross-section of the filter opening must be identical to the cross-section of the pipe. This measure will ensure the strength of the connection and will prevent the mechanism from subsequently moving aside.

Useful tips

To increase the service life of filters, you should follow these tips:

- evidence that the filter is clogged is a decrease in water pressure in all faucets;

- the more intense the water flow, the more often the structure should be cleaned; it is recommended to do this every 3 months;

- before unscrewing the outlet of the mud trap, you should substitute a basin or bucket, and also open the tap on one of the mixers;

- When cleaning cartridge filters, it is recommended not to wait until the walls of the flask are covered with a brown coating;

- If a stole gasket is used, the plug should be made hot before unscrewing, using a gas torch or a regular lighter.

Having figured out how to remove debris from the filter, it is worth remembering the regularity with which it is important to do this. In the process of clearing the blockage, it is important to take into account the design features of the installed model, as well as maintain the tightness of the threaded connections during reassembly

Additional structural elements

The design of the mud pan may also contain other elements that simplify maintenance or increase its functionality:

- in addition to the mentioned drain valve at the bottom, there is an air valve at the top of the mud pan to de-air the system when filling it with liquid;

- at relatively low pressure levels in the system, a transparent window can be provided on the side surface of the cylinder to assess the degree of contamination;

- Pressure gauges can be installed on the inlet and outlet pipes, by the difference in readings of which one can estimate the hydraulic resistance of the mud tank and, as a consequence, the same degree of contamination.

Mud traps can be produced with a flange connection and a “weld” connection. The first option is considered preferable, as it allows the mud collector to be easily replaced if necessary. However, such a replacement is rather an exceptional event: due to the simplicity of the design, mud collectors are extremely reliable, their service life is up to 30 years or more.

Purpose of the expansion tank

To maintain a certain pressure in the circuit, a compensation tank of the heating system is installed. This container is needed to compensate for the thermal expansion of the coolant liquid. If there were no tank, then when the water was heated, it would expand greatly and cause a critical increase in pressure in the pipeline, which could lead to an emergency.

Thanks to the presence of a tank, excess expanded liquid enters the container and the pressure in the system is maintained within normal limits. When the coolant cools, the lack of liquid is compensated by water flowing back from the expansion tank into the system.

Expansion tank design

There are two types of tanks - open and closed. The first are a metal barrel with a lid. At the bottom there is a pipe for connecting to the heating system. The open type tank is mounted at the highest point of the system. This container also has an emergency drain pipe, through which excess coolant is drained into the sewer system to protect against overflow.

The expansion tank is a closed type and has two chambers – air and water. At the bottom there is a connection pipe to the heating circuit. At the top there is a nipple for filling the air chamber and a pressure gauge for monitoring pressure. The closed type design must be equipped with an automatic air vent and a safety valve.

Both chambers are separated by an elastic membrane. When the coolant enters the water chamber, the membrane is pressed into the air compartment, which causes an increase in pressure in it. When the temperature of the coolant decreases, the liquid is squeezed out of the chamber back into the system due to the increased pressure in the air compartment.

Violation of the tightness of system elements

Violation of the tightness of system elements (pipes, connections, twists, welding, etc.) leads to a coolant leak, which, if not eliminated in a timely manner, can cause an emergency and lead to large material costs for its elimination.

In pipelines, leakage occurs due to pipe corrosion, which causes metal destruction, the formation of through holes (fistulas) and pipe ruptures. Corrosion of pipes increases during long-term operation, especially if the system is not flushed. Corrosion also increases when the system is filled with tap water (containing a lot of oxygen), and the system is frequently emptied, which allows air oxygen to enter it.

To prevent accidents in winter, it is necessary to inform the relevant services about any damage detected during the preparation for the heating season. When repairing, require careful pressure testing of the heating system in order to timely identify sections of pipelines weakened by corrosion.

Leaks can occur where pipes are bent, through cracks caused by improper bending. Leak points are eliminated by welding defective areas and replacing faulty areas.

To quickly (but temporarily) eliminate leaks on straight sections of a pipeline with a diameter of no more than 150 mm, install sealing clamps on the damaged section of the pipeline. Use this method when it is impossible to disconnect the damaged section and empty the pipeline. As soon as it becomes possible to disconnect the damaged section of the pipeline, remove the clamp and carry out repairs.

In a threaded connection, coolant leakage through leaks, as a rule, occurs due to poor-quality seals made during installation in the joints between the couplings and locknuts, cracks in the connections, torn and deeply cut threads. After determining the causes of the leak, either reassemble the threaded connection and re-seal it, or replace it.

Eliminate small leaks (fistulas) by welding linings to the pipeline. Fill small fistulas and cracks with welding. In flange connections, leakage occurs as a result of weak tightening of the bolts, aging of the gasket, its being made of low-quality material, or misalignment in the flanges. If, when tightening the bolts, the leak in the flange connection is not eliminated, then replace the gasket.

In a welded joint, leakage can be caused by poor welding quality, which is revealed by temperature expansion. Eliminate this malfunction by additional welding of the defective joint.

Varieties

To reduce the risk of boiler breakdown, increase the accuracy of measuring instruments and ensure a long service life of the equipment, it is important to understand the main types of devices and choose the right one

Polyphosphate

Polyphosphate units are considered a budget option for pre-purification and softening of water entering the boiler.

The operating principle of such a device is to pass liquid through a flask filled with special crystals. They ensure the formation of a protective film on the inner walls of the boiler and also slow down the formation of scale.

Photo 1. Polyphosphate filter for a gas boiler, filled with special crystals. They slow down scale formation.

The devices have a simple design:

- drain;

- flask;

- filler;

- lid.

The liquid enters the flask with filler through the lid, where it is passed through polyphosphate crystals. Next, it goes through the drain into the gas boiler tank.

Any device of this type requires periodic replacement of the filler - sodium salt crystals. As a matter of fact, this is the only difficulty in servicing them. The average lifespan of such a treatment plant is up to one and a half years.

Electromagnetic or magnetic for softening hard water

Electromagnetic devices are expensive, but the price is completely justified: the installation lasts a long time and allows you to obtain perfectly clean water at the output.

The principle of operation is that when the liquid passes through the flask, the salts in it disintegrate. Thus, scale will not settle on the walls of the boiler. Instead, the filter itself will be clogged with tiny salt particles, which is periodically washed.

Photo 2. Three magnetic filters for a heating system boiler; the scale in them breaks down into tiny particles.

Another characteristic is that under the influence of electromagnetic radiation, not only does the scale disintegrate into small particles, but also a thin film is formed that covers the boiler heat exchanger. Thanks to this, it remains protected and does not corrode for a long time.

We should not forget that electromagnetic and magnetic devices are different installations. At the heart of both is a magnet.

Attention! Electromagnetic devices are more powerful because they require connection to an electrical network. Ideal for gas boilers, as they perfectly soften water of any temperature

Magnetic installations are less strong and are not recommended for use with gas boilers if the water hardness is too high.

Magnetic devices consist of a metal case, inside of which there are a large number of strong magnets. Electromagnetic devices are additionally equipped with an electric drive, the operation of which allows the effect of magnets to be greatly enhanced.

Cleaners for gas heating boiler

The most commonly used water filters for gas boilers are polyphosphate and ion exchange.

Don't miss: Coal for home heating: how to choose?

Polyphosphate

These filters for heating boilers are a convenient and affordable option. The design is simple: it is a plastic flask, the inside of which is filled with sodium salt. Thanks to its crystals, a protective film is formed on the internal surfaces of the heating boiler and boiler, preventing scale deposition.

Liquid entering from the water supply system first passes through a filter, the crystals of which purify it, after which the water enters the pipes and the boiler itself.

It is mounted in front of the boiler.

Ion exchange

The device operates on the basis of a special filler contained in the cartridge. A special hydrogen resin plays the role of a cleaner.

The ion exchanger converts heavy metal ions into safer and lighter compounds, that is, the chemical structure of the water itself changes. Dissolved gases are discharged through special openings.