Purpose and advantages of nozzles

Gas burners (or nozzles) are designed to operate the stove on gas. Like other similar devices, the nozzle mixes fuel - natural or liquefied gas with air. As a result, the temperature in the oven increases.

Most often, such gas products are installed in baths , where high temperatures are required for a long time. However, nothing prevents you from installing a nozzle in your home in order to save yourself from the usual methods of kindling. In addition, such products have a number of significant advantages:

- Safety. Since such products work with explosive material, they are subject to strict requirements regarding reliability. You can verify this by reading the quality certificate.

- Availability of automation. Most gas products are equipped with automatic temperature control , which provides not only economical fuel consumption, but also protection from overheating or explosion of the furnace.

- Economical. As you know, gas is much cheaper than the cost of firewood, coal or electricity.

- Variety of fuels used. Many devices can operate on natural or liquefied gas.

- Ease of operation. The operation of gas devices for furnaces does not require any specific skills. In addition, some models can be operated from a special remote control.

- Ergonomics. Storing coal, firewood or other flammable materials requires a lot of space. The supply of fuel to the injector comes from the gas column.

Gas Spray Device for Furnace

Modern stoves and even fireplaces have been relegating wood to the background for a very long time, since today they work with gas, using the necessary equipment - a gas spray device.

Purpose and advantages

Gas burners were additionally designed to operate stoves, fireplaces, etc. Like other devices, burners mix fuel - liquefied gas or natural gas - with air, due to which a temperature increase occurs in this unit.

Very often, such devices are installed in rooms where high temperatures need to be maintained for many years. Today, nothing will prevent you from installing this equipment in your home; thanks to it, you can completely get rid of the usual method of kindling (fireplace, stove).

The burner, in addition, has a number of important advantages:

- Safety. Since this system deals with explosive material, severe good needs are used when installing it.

- If there is an automated device: at the moment, modern gas products are equipped with an auto-temperature mode, which provides a unique opportunity not only to spend resources practically, but also to protect the furnace from overheating or explosion.

- Economy. Everyone knows that today gas is very cheaper in cost than wood, coal or electricity.

- Control. To operate a gas-type furnace device, you do not need any special knowledge; in addition, some of the newest models operate using remote control.

- Ergonomics. To store flammable materials, coal or firewood, a special room is required. Since during operation of the burner, all the necessary fuel enters the nozzle through the gas column.

Types of burners

This design for the furnace represents reliable equipment that is used for continuous operation; it is based on high-quality materials that have undergone scrupulous multi-tier control, which allows us to provide particularly high-quality finished products.

The most famous brands on the market in our country are installations for stoves and fireplaces Mosklimat TERMO, Weishaupt, Giersch, Wester Line, Buderus.

In addition, jets are used not only in heating boilers, but also in industrial dryers, stoves, fireplaces and other installations that are of industrial importance. All devices of this type can be divided into groups: according to the principle of operation and the type of fuel used.

Principle of operation

In most cases, gas equipment for fireplaces and heating is not so simple in its design, operating condition and design, it all depends on the type, it has individual specific characteristics:

- atmospheric installations operate quite quietly, they have a simple and understandable design. In most cases, they are used in wall-mounted boilers or fireplaces, but if their power exceeds 80 kilowatts, then working in these systems will be unprofitable;

- forced air supply: the installation has a more complex structural system, it was specifically designed to provide a higher level of power. In addition, according to its own pricing policy, the installation significantly distinguishes itself from atmospheric systems.

During operation of the stove and fireplace, they provide a fairly high efficiency factor, about 94%. From an environmental point of view, these devices have also advanced; thanks to the installation system, gas is completely burned.

What is important to know when selecting a gas installation

Before choosing any particular burner, it is important to know the following:

- Specifics of the facility in which the burner will be used. First of all, you need to look at the area. If its dimensions are less than 12 m², then it is more advisable to buy a device that has a forced air supply, and if it is larger than a given size, then an atmospheric device will be required. The ventilation system plays an important role. If the air exchange in the premises is not as expected, then you need to install an inflatable system in it.

- Character of the furnace. If this model does not stop working on gas, then you need to turn to the atmospheric version; in other cases, forced air supply would be an excellent option.

- Power. There is an expression “the greater the power of the installation, the better,” but in such a situation it will not work. The power calculation is performed as follows: at 10 m? you need 1 kW of energy, depending on the size of the room.

- Manufacturer country. According to analysts, when choosing gas equipment it is necessary to look at foreign brands, since they are more durable and high quality than some domestic analogues.

When purchasing this equipment, you need to look at one serious invisible point. A gas stove is convenient to use in home (fireplace) and industrial conditions and is quite a successful invention, but you must always remember that stove fuel is explosive, so you do not need to resort to very low quality and inexpensive products.

Self-made device

Sometimes many people ask: “Is it possible to make a gas burner at home with your own hands?” Improving heating equipment increases its performance.

Maintenance of solid fuel boilers, as well as trouble-free control over the presence of coal or firewood in the combustion chamber, sometimes pushes the owners of these installations to re-equip them. Sometimes a similar possibility arises that a gas line can be connected to an object, but there is no desire to buy new heating equipment, then more qualified and knowledgeable people in this system begin to re-equip the device for heating the liquid with their own hands.

Anyone who has decided to refresh their own boiler in a similar way needs to know that any products made with their own hands must undergo specialized tests in a laboratory, after which the following documents must be received:

- Quality document. Issued to prove that a homemade torch is considered to be of high quality and suitable for use.

- A set of documents from Gosgortekhnadzor. They say that the handicraft product is documented in official sources.

- Checking the system, made with your own hands, for its compliance with all high-quality properties, as well as operation.

In order to collect a complete set of documents, go through all the authorities and officially register everything, you need to spend a lot of time and effort.

Because of this, despite all the advantages of working with your own hands, it is more advisable to buy an atmospheric burner for a boiler, manufactured in production. However, if you still have an irresistible desire to register the completed product, then you can do it with your own hands at home.

Type of fuel used

Whatever the device, whether factory-made or home-made, it will run on gas or other suitable fuel. At the moment, atmospheric installations are very popular; as a rule, they are installed in residential areas or in facilities with gas supply.

The second type of device with forced air supply (inflatable) is more extreme in design and does not stop working with the following types of fuel:

- diesel fuel;

- liquefied gas;

- gas.

Of course, the selling price of this installation is much higher, and in most cases it is installed where gasification of the facility is expected to occur soon.

(2 votes, rating: 4.50 out of 5) Loading.

Principle of operation

There are 2 types of such devices on the gas burner market:

Atmospheric nozzles draw air from the room where the stove is located. In addition, the operation does not require the use of complex automation. Thanks to this, the product has a simpler and more uncomplicated design. The main drawback is the requirement for good air circulation. Therefore, atmospheric burners should be installed in well-ventilated areas. However, some models have special sensors that monitor the oxygen level and, if its content is low, turn off the gas supply.

Supercharged products are equipped with complex automation , due to which they have a more complex design. Such products operate on the principle of forced air injection. Fans are responsible for this, regulating the pressure and volume of supplied oxygen. The main requirement for use is that air must be taken from the street.

Type of fuel used

Everything is much simpler here - the device can run only on gas or use several types of fuel. The first option is the simplest type of gas injectors and is the most popular in comparison with its “competitor”. As a rule, such products are installed in houses or apartments where there is a gas supply.

The second option has a more complex design, but can work with several types of fuel:

- liquefied gas;

- natural gas;

- diesel fuel.

Of course, the cost of such varieties is higher. Therefore, they are more often purchased in cases where gasification of the house is planned in the near future.

What are gas heating boiler nozzles used for?

Gas burners are an important part of a heating boiler. They are used to prepare a flammable mixture of gas and oxygen molecules taken from the air. Then the nozzle continuously supplies the finished substance to special holes and ensures combustion . The result is a fiery torch. In addition, the nozzle may have additional equipment aimed at safety, automation of system operation and ignition.

Photo 1. Gas nozzle in working condition. It is possible to regulate the boiler power.

Operating principle

The gas unit is responsible for controlling the operation of gas injectors, which processes the signals from the gasoline electronic unit for gasoline injectors. The volume of gas for supply to the internal combustion engine (internal combustion engine) is calculated based on the temperatures of the gas and the reducer, the pressure of the gas mixture and other parameters.

Injection technology using an HBO gas injector intersects with the idea of gasoline injectors. An electromagnet (solenoid valve) is required that moves a part (rod) to open the flow of fuel from the reducer, which evaporates the mixture, to the intake manifold. The nature of the fuel affects the cross-section of the injector channels - for gas the cross-section is larger, because the volume of the gas mixture exceeds the same dose of gasoline (about 250 times) and greater throughput is required.

To ensure such tasks, the gas injector of the HBO has a reduced electrical resistance. Gasoline injectors have a resistance of 16 - 17 Ohms, while for gas it is 1 -3 Ohms.

It is important that to ensure the speed of operation of a gas injector, electromagnetic coils of greater power are needed than for gasoline injectors. There are other design differences. The petrol injector opens with a 12V pulse. Applying such voltage in the case of a gas mixture will disable the opening element. Therefore, the 4th generation HBO injector opens due to the action of a short-term pulse, the interruption speed of which is quite high. As a result, the winding of the part does not overheat and does not burn out. This method is called pulse width modulation.

Types of appliances using natural or liquefied gas

Gas injectors are distinguished by the type of fuel used in the system. They are available for natural gas from the mains or for liquefied gas from a cylinder. They have different diameters and operating pressures. As a rule, burners for both types of fuel are included with the heating device.

Injectors are classified according to the principle of operation of the device, how the gas-oxygen mixture is prepared, how the gas is supplied to the combustion chamber and some other features. There are two main types of injectors: fan or atmospheric.

Fan

The design of these nozzles is considered complex and includes a built-in fan and turbine , which is why they are also called forced-fan nozzles. Air is forced injected in controlled volumes, so the combustible mixture is prepared in strict proportions. A boiler with such components is productive and economical. Used in devices with a high degree of automation.

Important! This type depends on electricity. Without electricity, the gas supply will be cut off!

Advantages of fan injectors:

- economical, reduce fuel consumption;

- combustion is under absolute control;

- power is adjustable;

- The efficiency is significantly higher than that of atmospheric ones;

- can be used in houses where there is no chimney;

- no need to reconfigure for a different type of fuel.

Photo 2. Fan-type nozzle for a gas boiler. The device contains a fan and a turbine for pumping air.

Minuses:

- high price;

- energy dependence on electricity.

Atmospheric

This type of equipment is usually used in floor-standing boilers for houses with an area of no more than 100 square meters. The power is adjusted at the factory.

Reference. When changing the type of fuel, reconfiguration is required.

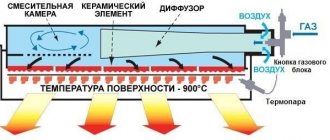

These burners take air to prepare a combustible mixture directly from the room where the heating device is installed, that is, from the atmosphere, hence the name. The atmospheric nozzle operates on the principle of an elementary ejector . Pressurized gas is directed through specially shaped nozzles. These nozzles have access to normal air from the room, which is drawn into the system.

The finished mixture comes out through slits located a little further away, where ignition occurs. The air becomes rarefied as it travels from the nozzle to the outlet, which creates a constant draft.

Gas heating - air, independent, special equipment

Currently, gas-type heating is considered a fairly popular type of heat supply for private and high-rise buildings. A gas heating system involves placing devices with a heating function in the middle of the room that is heated. A gas heating system, in addition to the main appliances, also includes gas pipelines that provide fuel supply and heat transfer, automated devices designed to safely use gas, and shut-off and control valves.

Gas heating of a privatized house

There are many different types of heating equipment that operate on gas fuel. Some equipment is used for personal homes, while other types are more suitable for heating industrial buildings.

Gas heating equipment includes: boilers, design radiators, infrared gas emitters. In most cases, the latter type is used in those rooms that have sufficient area. The emitters are located mainly under the ceiling surface.

An infrared heating system on gas is a casing that has a reflector turned towards the floor surface with a tiled attachment made of flat tiles with holes at the bottom.

There is space between the casing and the nozzle. Actually, the fuel mixture is supplied here, heating the tiles to high temperatures. After which the gas burns on a hot tile nozzle, which radiates heat into the space of the room, heating it in the same way. When using this type of heating equipment, gaseous, liquid and solid gas substances are practically absent; their remains are removed by the ventilation system.

Gas IR heater

If you need to install gas-type heating in a private house, then the best option would be a gas boiler. You should select such gas heating equipment carefully, since the comfort and warmth in the room actually depends on the boiler.

The most significant characteristic of a gas water heater is power. Thus, gas boilers come in small (4-65 kW), medium (up to 1700 kW) and large (up to 15000 kW) power.

Gas boiler

Depending on the power of the gas water heater, the type of burner and unit is selected. Moreover, you need to take into account the fact that wall heating devices in most cases have a small power, and floor heating devices have a large power. Also, wall-mounted and floor-mounted models are distinguished by the fact that they have a different design and material of the pipe coil. For wall-mounted options, copper heat exchangers are often used, and for floor-mounted ones, cast iron or steel.

Moreover, boilers that use gas heating systems can be single-circuit or double-circuit.

Single-circuit units heat only the room. So, hot water comes from an electric storage water heater. Double circuits are intended not only for heating purposes, but also for providing hot water. Such boilers can be instantaneous (with low hot water consumption) and with a built-in storage electric water heater (a free atmospheric burner heats the water, or a heated towel rail is indirectly connected to the boiler).

Gas boilers consist of certain components:

- Atmospheric burner. This is a perforated rectangular design. In the middle it consists of similar elements as a gas atomizing device for heating.

- Pipe coil. In the middle of this box there is a heating device with pipes containing a coolant.

- Circulation pump. Because of it, pressure is ensured in the line.

- Expansion tank. Designed to temporarily remove the heat carrier when it heats up and expands.

- Combustion product removal device.

- Automation. This is the boiler operation control unit.

Gas water heater diagram

Gas convectors

A popular method that uses network gas heat supply is gas cylinders. In addition to the good cost, this method has a number of other good qualities.

First of all, we note the ease of installation. Standardized fasteners are used here, making the installation of pipes simple and you can create it yourself. But setting up the equipment must be done by specialists.

Modern gas convectors are quite compact. As a result, they fit perfectly into any design.

A special advantage is safety. After all, everything here is controlled by automation. Moreover, gas convectors are durable. Their service life depends on the material, approximately 20-50 years.

Gas convector

Gas convectors are capable of operating from the gas mains, and also independently if there is a cylinder with liquefied gas. The number of installed cylinders depends on the area of the room. Such cylinders are installed not only indoors, but also in specialized cabinets located near the outer wall of the building. If gas heating containers such as cylinders are used, then the heat supply will be very convenient and profitable.

Installation of a gas heating system

To install a gas space heating system, you need to implement a couple of steps. First of all, a heating system design is drawn up, then all the equipment is purchased, after which the system is installed and filled with a coolant.

After the project and gas heating scheme have been drawn up and agreed upon with the gas service, all materials and equipment have been purchased, the time comes to install the heating system. Installation must be done by specialists. First of all, pipelines and heat supply risers are installed, automation for control, and specialized devices for regulation are installed. Next, the heating system is started and optimized.

Good quality gas heating system

Among the obvious positive qualities of a gas heating system, we note the following:

- low inertia (quick access to the desired operating mode, quick heating of rooms);

- high efficiency (80-95%);

- there is no need for continuous provision of fuel supplies;

- independence from electricity;

- As a rule, air conditioning systems, bathhouses, area lighting, etc. will operate from a gas heater;

- the functioning process is as automated as possible;

- such systems comply with today’s environmental standards, as they emit a minimum of substances that are harmful to health;

- no operating costs;

- you can change the temperature;

- the cost of the equipment is quite optimal.

Independent gas heating system

If you do not want to connect to a common line, or it is not available on the site, then you can create individual gas heating. Thanks to such a system, heat consumption will be carried out correctly, and there will be no losses in the main networks.

Independent gas heating system

It is most advisable to create a project for an independent gas heating system when designing a house. After all, the location for the boiler plant and gas tank must be determined immediately. Fuel from the gas tank to the house must be supplied underground using a gas pipeline.

In addition to the fact that this type of heating system creates a heating role, it can also provide an uninterrupted supply of hot water and heat supply from the kitchen stove.

Other options for using gas for heating

Gas-type air heating is becoming quite popular. In most cases, it is used in industrial enterprises, warehouses, and also entertainment complexes.

Nowadays, gas air heating has also begun to be used in private homes.

The meaning of stove heating devices is that air is supplied through a pipe coil using a fan. These devices are varied - depending on the type of fan, heat carrier, power.

Air heating gas type

Along with air heating using gas, gas heat supply guns are also used. Such guns (heating systems) are available not only with natural gas, but also with bottled gas. All guns are direct-heated; they do not use combustion product exhaust. In most cases, they are used for heating warehouses, greenhouses, and open areas.

How to choose a device

To select the appropriate component for the boiler, you need to study the technical characteristics of the device and find out the combustion power of the heating device.

It is better to consult a specialist. The most important factors when choosing are power, range and control method.

First, select the nozzle based on power. It should exceed the boiler power , but not very significantly. The range of system power control will depend on this.

By type of regulation, nozzles are selected based on the size of the room . For a private boiler house with low power, any type is suitable; for industrial scale or for very large houses, systems with smooth two-stage or modulated control are needed.

Replacing the gas injector

installation steps :

Photo 3. The process of dismantling the burner from a gas boiler. This work should only be carried out by a specialist.

- Fastening of fittings.

- Nozzle installation.

- Connecting the electrical connector.

- Installation of a gas train to the main line.

- Start the system.

- Setting and adjustment.

Attention! Only a specialist has the right to install components on the boiler

Materials and tools

To replace a nozzle in a gas boiler, you will need a minimum of tools: instructions for the boiler and burner, a screwdriver, soap solution and a brush.

Site preparation and dismantling of the old structure

dismantling sequence :

- close the gas supply valve;

- remove the nozzle from its installation location;

- carefully unscrew it.

Preparing the site involves removing excess dust , ensuring free access to the boiler and supplying fresh air to the boiler room.

Fan burner installation instructions

The first stage is extremely simple. All fastening elements for the nozzle are included. You only need to check whether the gaskets are installed correctly at the mounting points.

The second stage is also not difficult if a suitable burner has been purchased.

If not, then replacement is necessary; operating the system with unsuitable components is strictly prohibited. The nozzle is installed in place so that the nozzle does not touch the walls of the hole in the heating device. Screws are screwed into the mounting holes.

The connector can simply be turned on if the inputs on the boiler wires and on the burner match . Otherwise, the burner comes with a suitable connector; you need to replace the one on the boiler wire with it.

Important! Make sure that the electrical circuit of the boiler is compatible with the burner! Schemes are given in the description of the boiler and burner.

A shut-off valve must be installed on the gas pipeline to shut off the gas supply to the burner. The burner is connected to the pipe either using an anti-vibration coupling or a bellows pipe, since during operation the turbine vibrates quite noticeably, which leads to depressurization.

System startup and testing

The heating device is connected to the power supply, and the valve on the gas pipeline is opened. For the first time, turn the valve to minimum.

If there is a gas supply regulator, then it is set to maximum . Then press the button on the dashboard. The fan turns on, purging occurs and a spark appears, the gas ignites.

This may not happen the first time, because air accumulates in the system. If the burner is blocked, it is unlocked according to the instructions and started again.

The boiler be operated without adjustment . It is better to carry out the adjustment using a gas analyzer and special tables, but you can also do it by eye. To do this, look at the flame through a special viewing hole. The gas supply is gradually reduced so that the flame turns bluish instead of an orange tint; this will be the optimal mode.

If a hum is heard during combustion, then the flame length is reduced .

Finally, check the system for leaks using soapy water. The solution is applied to the joints; if there are no bubbles, the system is sealed.

Gas heating of a privatized house: independent, main, air

The heat supply method, in which flammable gases serve as fuel, involves the placement of radiators in the rooms that are heated. Today, the most famous type of heat supply for country and high-rise buildings can be called gas-type heating.

In the design of this type of heating system, in addition to the main devices, there are also gas pipelines, they require fuel transfer and heat transfer, automated devices that are necessary to reliably use gas, a device that ensures hermetically sealed passage.

Types of designs

There are slightly different classes of heating equipment that run on combustible gas. Some devices are installed in houses outside the city, while other installations are perfect for heating premises for industrial needs.

Equipment for modern heating stoves consists of: boilers, batteries, IR heaters. Basically, the latter device is used in similar rooms that have impressive dimensions. Quasars are installed in most cases on the surface of the ceiling.

The design of electromagnetic heat supply is a box that has a reflector turned towards the bottom with a faience nozzle made of thin slabs with holes at the bottom.

There is a gap between the box and the nozzle. This is where the fuel mixture comes in, which heats the tiles to a high temperature. Then the gas begins to burn on the hot earthenware nozzle, which gives heat to the houses, thus warming them up. When using this version of the heating system, there is practically no combustion waste, since the remaining gas waste is removed by ventilation.

Heating system with gas furnace

Gas boilers

When you want to install gas-type heating in a private house, the best replacement is a heating boiler. The choice of this heating system must be approached with great care, since comfort and home warmth can depend on it. A very important property of gas-burning equipment is its boiler capacity. They come in small (4-65 kW), not too high (up to 1700 kW) and the largest (up to 15000 kW) capacities.

The type of gas burner and appliance depends on the power of the gas appliance. In addition, it should be taken into account that wall heating boilers are of low power, while those standing on the floor are, on the contrary, large. They also have differences in the structure of the structure and what materials the pipe coil is made of. Copper heat exchangers are mostly used on the wall surface, while cast iron or steel heat exchangers are installed on the floor.

Boilers used for gas heating are 1-circuit or 2-circuit.

Single-circuit boilers are installed to heat only the room. The heated water comes out of the water heater. 2-circuit boilers are installed not only for heating supply, but also for supplying hot water. For low hot water consumption, these devices are flow-through and have an electric storage water heater built into them. An atmospheric burner heats the water in it, or a heated towel rail is connected to the boiler.

Devices for burning natural fuels have several elements:

- Atmospheric burner. This is a perforated quadrangular structure. The heating gas spray device is located in the middle of it.

- Pipe coil. A heating device with a coolant and pipes is mounted in the middle of this casing.

- Circulating pump. With its help, pressure is generated in the line.

- Expansion tank. It is not needed for continuous storage of water when it expands as it heats up.

- Combustion waste collection device.

- Automation for operation of the entire heating system.

Gas water heating device

Wall-mounted air heater

The most well-known method used for heating with liquefied gas is traditional gas cylinders. In addition to good value, it still has many other positive qualities.

The first is ease of assembly. Here they use standard fasteners, thanks to which the assembly of pipes is not heavy and you can do it yourself. But still, professionals should set up such equipment.

Current gas convectors are small. Thanks to this, they can be perfectly combined with absolutely any decor in the house.

The main positive quality of such a system is its safe operation. Since control over everything is created by the boiler automation. In addition, the radiators are designed to last for a long time. Of course, this depends on the material from which they are made, in most cases it is about twenty to fifty years.

Gas convectors, as a rule, will operate from a gas pipe, and also separately if there is a gas cylinder. The number of these cylinders depends on the dimensions of the room. They can stand not only indoors, but also in closets; when equipped, they are placed against the walls on the outside of the house. When such gas cylinders are used, heat supply becomes good and inexpensive.

Wall gas heater

Assembly of gas heating equipment

Installation of gas heating systems in a house requires several periods:

- First of all, the design of the entire system is carried out, then special equipment is purchased, after which the assembly is carried out and the entire system is filled with water.

- When both the project and the heating scheme have been created and signed by gas service professionals, all equipment has been purchased, the time has come for installing the entire system.

- All assembly is done by professionals. The first step is to assemble the lines, risers for heating, attach the automation and control devices. After all, gas-type heating is started and optimized.

The benefits of central heating

Among the obvious good qualities of this heat supply, it is necessary to highlight several:

- Not high activity (instant access to the required working mode, instant heating of the room);

- High efficiency (80-95%);

- There is no need to constantly supply fuel;

- Network independent;

- Air conditioners, baths, area lighting, etc. operate from such heat supply;

- the workflow is almost completely automated;

- these systems are commensurate with modern environmental standards, since they contain quite a few substances that are harmful to health;

- no operating costs;

- it is allowed to change the temperature regime;

- The price of the equipment is quite good.

Individual heating on gas

If you do not want to cut into a common highway, or there is none on the site, then you need to make an independent gas heating system. A system of this type uses heat economically, and there will be no losses in the main line.

It’s great to make a plan for such a heat supply when developing a house project. Since you need to immediately find where the boiler plant and gas tank will be located. Fuel from it must be supplied to the premises underground using a gas pipeline.

Plus, such a boiler installation not only performs the heating function, but also provides hot water and gas supply to the stove.

Independent system diagram

Gas heating through air

In many cases, it is used in industry, warehouses and entertainment systems.

They also began to provide similar heating to cottages.

The working principle of the stove heating mechanism is that masses of air penetrate the pipe coil and are supplied into the room with the help of a fan. These devices are different - they depend on the type of fan, heat carrier, power.

Along with stove heating, gas guns are also used. They can be not only gas-powered, but also in cylinders. All these guns use direct heating and have no combustion waste. They are mainly used for heating warehouses, greenhouses, and open areas.