When installing vapor barriers, the seams of vapor barrier films are sealed using special types of construction tape. The use of adhesive tape that is not intended for such work will lead to its rapid peeling off, breaking the tightness of the seams and penetration of moisture into the thermal insulation layer. This will entail a loss of the thermal insulation properties of the insulation.

Purpose of vapor barrier tapes

Before looking for solutions for gluing a vapor barrier to a wall, joists or rafters, you need to understand the functional significance of the accompanying material. It is difficult to imagine building a house today without the use of various types of insulating boards and sheets. These are products from the category of insulation, films for creating a protective layer against direct contact of the structure with water and the penetration of vapors from the inside or outside of the building. Installation of each type of finishing involves the formation of a monolithic cover to prevent the appearance of cold bridges and the penetration of moisture into the walls, floors and roofing pie.

Let's take a closer look at the functional purpose of tapes with a sticky substance on one or both sides for gluing vapor barriers. Roll samples in commercial form have a limited width (usually within 1-1.5 m). Because of this, the protective coating on one or another plane is often obtained with seams through which moisture can penetrate.

Roll type insulation with limited width Source sense-life.com

To form a monolithic barrier, the edges of the canvases are overlapped by 100-200 mm. Additionally, joints of this kind are sealed using specialized tape. An exception where it is not necessary to perform this procedure is the formation of waterproofing protection on a roof with a cold attic. Here it is enough to place each upper horizontal sheet on top of the one lying below. Moisture will automatically roll down the inclined surface without penetrating inside the house.

By category

Vapor barrier tape is a special construction tape that is used to seal the seams of vapor barrier films. Using unsuitable adhesive tape leads to its peeling off and moisture getting into the insulation. As a result, the house loses its thermal insulation properties.

In this article, we will look at the main types of adhesive tapes for vapor barriers, help you make the right choice, and tell you about the nuances of installation.

Classification of adhesive materials

To choose the right way to glue the vapor barrier together, you need to consider the entire range of self-adhesive tape options available. All samples can be divided into two groups, the defining criteria of which are the methods of installing protective sheets. So, the overlap can be sealed on the inside with double-sided tape or on the outside with adhesive on one side.

Example of double-sided insulation tape Source soltechonline.com

It is worth noting that stationery transparent film and painting paper equivalent or electrical tape cannot be used here. Their performance characteristics are not designed for changes in humidity with temperature, or for the long-term effect of the glue (10-15 years for specialized samples). Vapor barrier tape is characterized by the following properties (general version):

- the operating temperature range ranges from -40 to +80 degrees Celsius;

- water absorption coefficient is limited to 0.2% per day;

- high adhesive ability to most building materials (concrete, wood, metal, plastic, glass).

All of the listed values are characteristic of insulating tapes, but two more types of adhesive tapes differ in temperature conditions. “Summer” ones are more focused on operation at low thermometer readings, “winter” ones - at positive ones. The parameters also differ depending on the technical design (composition, structure). So, there are the following effective solutions for how to use tape to glue a vapor barrier:

- Aluminum.

See also: Catalog of companies that specialize in home insulation

This is a tape made of metal foil with a thickness of 30-40 microns with a paper protective layer for the adhesive. The width of the canvas is 50-100 mm. It is used for various types of vapor barrier fabric. Most often used for installation of foil-type insulators, insulation and underlays for floor coverings, which are laid end-to-end (without overlap).

- Reinforced aluminum. This material is distinguished by a reinforced base in the form of a reinforcing mesh with a polymer nature. The width of the tape is the same as for aluminum samples.

- Polypropylene. The budget option is considered not a better solution than gluing vapor barriers together. This tape is inferior in reliability to alternative tapes, since depressurization of joints is often observed after a short period of time. Here, as a rule, an adhesive with low peel strength is used. The roll width of almost all manufacturers is limited to 50 mm, thickness – 100 microns.

Double-sided polypropylene sample Source tvtok.ru

- Butyl rubber. This sample is characterized by maximum adhesion to vapor barrier sheets made of polyethylene. Compared to the light aluminum version, there is more weight here (several times). The width of the tape ranges from 10 to 50 mm. Experts note that this solution makes it possible to seal joints with the highest quality.

Butyl rubber sample Source prom.st

- TPL (textile polyethylene tape). A rubber-based composition is used as an adhesive on a woven base (middle layer). The thickness of such a sample is 200 microns.

In addition to tape-type sealing devices, special adhesives for vapor barriers are used to form strong joints between membrane sheets and adjacent structures. This is, as a rule, a polymer dispersion with a consistency close to a paste. Apply the product to membranes and adjacent structures made of concrete, wood, metal or plastic. One of the main advantages is excellent adhesion to surfaces with varying degrees of roughness. But there are restrictions on the operating temperature; installation work is carried out only in warm conditions.

Which tape is best for vapor barrier?

Vapor barrier tape is selected according to needs, materials and desired results. What to look for when purchasing:

- lifetime;

- degree of adhesion to various materials;

- resistance to heat;

- property to absorb water;

- resistance to ultraviolet radiation.

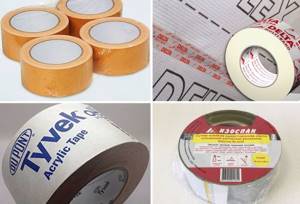

It is better to make a choice in favor of proven brands:

- Izospan is a durable butyl rubber tape with a metallized base.

- Delta is a universal single-sided tape made in Germany. Delta tape is used for bases made of metal, wood, and hard plastic.

- Tyvek - universal tapes of single-sided and double-sided types. Used in extreme humidity conditions.

- TechnoNIKOL is a double-sided tape with a polypropylene base. Easy to use, provides reliable protection from moisture, and has good adhesion to most building materials.

Recommendations from installation specialists

The rules for gluing various substrates are the same for all types of construction work. The surface must be clean, dry and free of oily stains. If necessary, before gluing the vapor barrier, a degreaser and a primer are used, followed by mandatory drying of the elements of the supporting structure.

An example of a universal degreaser for construction work Source t-dek.ru

Only in this case will high quality adhesion be ensured. It is also necessary to comply with the conditions for temperature and relative humidity. More often at the time of installation this is a lower limit of +5-+10 degrees Celsius and a humidity level of about 50-60%.

Before sealing the joints using single-sided tape, the film must first be smoothed over the surface using a mounting roller. The tape itself is glued without tension, which subsequently causes peeling. Samples with adhesive on both sides of the top protective coating are removed only after fixing the vapor barrier in the upper part to avoid the appearance of wrinkles. Observing the horizontal arrangement of the canvases, it is recommended to fix the bottom row around the entire perimeter with double-sided tape for vapor barrier and insulation of joints.

If adhesive is used for a vapor barrier film, it is applied to the work area in a thin strip in an even layer. It is important that the paste is throughout the entire area without gaps.

Special glue in a tube for a construction gun Source doerken.com

After this, the insulating sheet is glued without exposing the fastening composition to air. Light pressure is applied to the membrane or film to avoid residues protruding beyond the edges.

Types of adhesive tapes for vapor barriers

When choosing a vapor barrier material for the construction of a roofing pie, you need to remember that the adhesive tape for connecting the panels and the film must be produced by the same manufacturer. Often, when using products from different brands, there is no gluing effect or it does not last long.

The membranes are joined using connecting tape specifically for vapor barrier, because it eliminates the formation of capillary moisture in the connection area:

- panels laid next to each other;

- adjacency to elements passing through the roof - chimneys, antennas, communication risers;

- adjacency to adjacent building structures, including parapets, panoramic windows, doorways, etc.

The choice of vapor barrier material to protect structures from evaporation depends on the conditions of the upcoming operation, which must be unconditionally taken into account before purchasing. In addition, you need to carefully study the instructions for installing a vapor barrier so as not to encounter the impossibility of installation right on site.

Single-sided tape for tight joints

This type of adhesive tape is used to join sheets of vapor barrier material by placing an overlap over the edge that overlaps an already installed adjacent sheet.

Single-sided tape with the DELTA® logo and the product name TAPE FAS 60/100 is a 6 cm wide strip with a laminated cardboard base and an acrylate adhesive on the working side. This tape cannot be used for gluing film materials made from chlorinated paraffin, and gluing to boards made from recycled materials is not allowed. It is not suitable for installation in swimming pools and bathrooms.

It is used exclusively for carrying out work inside a furnished attic or other room. Suitable for connecting vapor barrier protection to nearby smooth metal, wood, and plastic surfaces.

In the line of domestic products, an analogue is Izospan SL - an adhesive tape designed for hermetically sealing vapor barrier strips.

Self-adhesive self-expanding version

In the line of the German company Delta, similar products are represented by a tape with the nomenclature name DELTA-KOM-BAND K 15. It is used in the formation of sealed and airtight connections to adjacent structures, walls of ventilation shafts, brick chimneys.

In the state offered to the buyer, the tape is compressed, resulting in the width of the sales offer being only 4 cm; after straightening the material, the width of the strip reaches 17 cm. It is made from polyurethane foam, reinforcement is installed on one side of the tape and an acrylate adhesive is applied.

This type of adhesive tape is suitable for outdoor work because... can be used for gluing to damp and even frost-covered surfaces. It is first glued to the film, and then pressed against the wall with a strip.

Elastic self-adhesive tapes

To seal passages through the roof of communication risers, antennas, narrow steel pipes, bitumen-rubber single-sided tape DELTA-FLEXX-BAND F 100 and DELTA-MULTI-BAND M 60/ M 100 is used.

These are universal adhesive consumables suitable for work both inside and outside the building. They are used in the arrangement of penetrations, they compensate for linear movements of building structures relative to each other, allowing them to move without losing the tightness of the constructed junction.

Universal adhesive tapes are used to repair damage to all types of insulating films, but are only suitable for gluing to smooth surfaces. Since they are designed for outdoor work, during development they were given resistance to UV and other atmospheric hazards.

The product range from the Izospan company includes a one-sided, weather- and UV-resistant tape labeled Izospan ML proff.

Double-sided tapes and their use

German-made double-sided tape, resistant to atmospheric negatives, with the nomenclature name DELTA-BUTYL-BAND B 15 is made of butyl rubber. Tape with two adhesive sides is used in joining vapor barrier panels and in eliminating defects such as breaks and cuts.

Double-sided adhesive tapes for insulating films are used for both external and internal types of work; they are suitable for making connections to roof windows, rafters and rigid flooring. When making connections to building structures, it is necessary to install clamping strips to ensure perfect fixation.

In the line of Russian adhesive tapes, Izospan KL has similar characteristics. This tape is glued over the rolled-out vapor barrier strip, departing from its edge at the distance specified by the manufacturer. First, only the lower anti-adhesive paper is removed, after gluing, the upper one is removed, on which the next vapor barrier sheet is applied.

Metallized tapes for vapor barriers

When connecting vapor barrier materials to the metallized side, adhesive tapes coated with aluminum are used. The product from the German brand of roofing materials is called DELTA-POLY-BAND P 100.

This is a one-sided tape, it is made of polypropylene, with a metal coating applied to the outside. The width of this type of tape is 10 cm, its gluing ability significantly exceeds the properties of conventional tapes.

In the line of Russian products, Izospan FL Termo has equivalent qualities; this adhesive tape allows you to create a single heat-reflecting plane like a German product.

Adhesive tapes with a metallized side serve well in rooms with non-standard operating humidity and temperature conditions. They are used to set up steam rooms in Russian baths and Finnish saunas that supply dry steam. Adhesive tapes are laid on dried and degreased vapor barrier sheets.

Briefly about the main thing

Vapor barrier and hydrobarrier made of rolled materials must be monolithic, so the sections are mounted with an overlap of 100-150 mm, and the joints are sealed.

To glue the canvases, fix them to the supporting structure and seal the joints, special paste glue or tape is used.

Vapor barrier tapes are distinguished on one or both sides with an adhesive substance, according to composition and purpose regarding adhesion and operating conditions.

Office tape and paper (painting) tape are analogues of vapor barrier tapes, but are not allowed to work with vapor barrier membranes and films due to their short service life and low peel strength of the adhesive.

Installation work is carried out taking into account the main requirements: cleanliness, no oily stains, dry and, if necessary, primed surface, no folds on the edge.

Ratings 0

Features of Ondutis mounting tapes

Ondutis BL is a self-adhesive double-sided tape on anti-adhesive paper. It is used for gluing vapor barrier films and sealing in places adjacent to roof passage elements (stove pipes, ventilation ducts, drain funnels, etc.) and to hard mating surfaces of concrete, wood, brick. Using this tape, a reliable vapor-tight connection is created with a service life of 15 years.

Ondutis ML is a self-adhesive double-sided fabric-based tape. The synthetic rubber included in the tape provides a strong, sealed connection for 15 years. This universal tape is used for gluing and sealing overlaps of vapor barrier films when installing vapor barriers on roofs, ceilings and walls. The material is non-toxic and harmless. Standard tape width is 50 mm.

Installation features

To increase the reliability of installation, they resort to the double gluing method. This method involves overlapping fastening using double-sided tape, and then gluing the connection on one side. Installation steps:

- the film surface undergoes thorough preparation: cleaning, drying, degreasing;

- the base is also prepared, then the lower part of the vapor barrier film is applied;

- adhesive double-sided tape is glued along all edges of the film, the protective layer is removed;

- the second canvas overlaps the first;

- the seam is pressed tightly for maximum fixation;

- the resulting connection is glued with one-sided material, while ensuring uniform distribution of the tape over the two canvases.

The need to create sealed joints of the vapor barrier layer

A vapor barrier layer is laid on the inside of the room, which prevents moisture from penetrating into the thermal insulation layer from utility and living spaces. If the vapor barrier has a sealed layer, which is ensured thanks to a special adhesive tape, then it will retain warm air and prevent the penetration of cold masses from the street.

If you use adhesive tape for vapor barrier, this will help restore the microclimate in the house, preventing excessive dryness of the air, because cold masses from the street have a relative humidity that is less than what is comfortable for humans. If you are also concerned about the issue described in the article, then you need to choose a high-quality tape. It is only important to decide which company to prefer.