Bypass assignment for heating. Why is it needed? Operating principle and installation rules

Table of contents:

- What is bypass in heating systems

- Why is this element needed in a heating system? In a single-pipe system

- In a two-pipe system

When installing a heating system, it is important to create a design that will operate with maximum efficiency and will not lose efficiency due to failures in coolant circulation.

For this purpose, it is necessary to use a bypass : the element serves to ensure the safety and stability of the hot circuit and does not allow it to fail, even if a leak occurs on the heating radiator.

Installation

bypass in a one-pipe system

bypass on the mains pump line

There are 2 options for installing a bypass together with a pump that circulates water in a single pipeline: on a new or old circuit. There is no difference between them either during installation or during heating operation.

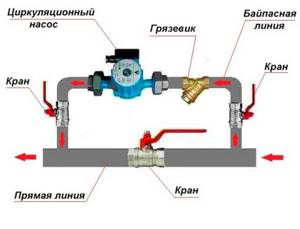

When installing a bypass together with a pump, the following rules must be observed:

- Firstly , on the main circuit in the middle of the bypass pipes, it is imperative to install elements blocking the pipe. This will allow the coolant to flow through the bypass with the pump, without the effect of reverse flow.

- Secondly , it is extremely important to correctly place the pump on the bypass structure: the impeller axis must be located in a horizontal position, and the cover with stamps must be directed upward. If there are inconsistencies, the cover can be twisted by unscrewing the four fasteners on the pump body. This positioning of the marks solves 2 problems: it makes it easier to access them for connection and, in the event of a leak, it reduces the likelihood of liquid getting on them.

- Thirdly , only a ball valve should be installed as a lock, and not a check valve.

Because with the valve the circuit will begin to function like this:

- A running pump accelerates the flow of water in the circuit.

- The coolant flows through the bypass into the main pipeline in opposite directions.

- According to the effective vector, it goes without restrictions, and according to the reverse vector it is delayed by a check valve.

- It automatically closes and does not allow water to circulate normally through the two pipes.

Thus, increased coolant pressure is created on the valve plate precisely after the pump, because the flow rate behind it is always faster. In theory, when the pump is turned off, the coolant no longer acts on the valve, which in this case does not close.

This allows the liquid to move by gravity through the main pipeline without getting into the bypass. But in reality, the bypass with the valve does not function as it should.

The problem is that the valve disc generates excessive resistance comparable to a whole meter of pipe. Under the conditions of the gravitational circuit, water will not be able to overcome it, and its circulation will stop completely.

If the valve is replaced with a standard ball valve, it becomes possible to direct the vector of water flow in the circuit.

bypass with pump

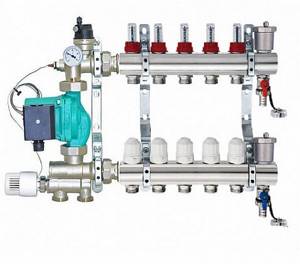

In order to install a bypass with a pump in the heating circuit, you will need the following set of parts:

- welded-in line pipes with threads;

- ball valves mounted on both sides;

- corners;

- pre-filter installed in front of the pump;

- a couple of American women to dismantle the pump for maintenance and repair.

- Installation in front of the radiator. What does it matter? Installation rules: how to install.

A bypass element is installed in front of the radiator in case water stops circulating inside it for some reason, then its circulation along the bypass throughout the rest of the circuit will continue, despite the malfunction of one of the elements.

It performs the following functions:

- Ensures continuous movement of coolant along the main heating line.

- Allows you to regulate the water temperature in radiators.

In heating systems with one main circuit, water circulates in it, sequentially transferring heat to 1, 2 and subsequent radiators. Thus, as it passes through each subsequent radiator, the thermal energy of the water decreases, which means that the first heating element will heat up much better than the last.

Types of bypasses used in one-pipe and two-pipe systems

Depending on the systems in which it will be used (one-pipe or two-pipe), the bypass can be divided into two types:

- Automatic (uses a check valve);

- Manual (no check valve).

Automatic bypass

Due to this, the radiator batteries do not heat up excessively, and the coolant passes to the next element of the heating system. Automatic bypass is used to regulate the water supply and control the heating temperature of specific rooms. Such a device can carry out partial or complete removal of coolant from radiators. The circuit with a check valve is used in systems with forced circulation. In the event of a power outage, the pump will stop working, however, by shutting off the flow of water to it and opening the tap on the main pipeline, the natural circulation process can be started. The check valve is used as a constant source of circulation for the pump. It works offline and turns on as needed. An automatic bypass must be installed together with the pump.

Manual bypass

A circuit without a check valve is usually installed in multi-storey apartments. If it is necessary to repair the heating or replace the radiator, you need to turn off the tap running through the pipe. Such an action will lead to the fact that residents of the lower floors will be cut off from the source of coolant. It is in such cases that the device finds its practical purpose. A manual bypass allows you to install a bypass by disconnecting the main heating system from the batteries in the room. By turning off just two taps, you can turn off any heating elements. This function allows you to carry out any type of repair without compromising the integrity of the system. This explains the recommendations for installing a manual bypass in the heating system in apartment buildings.

Heating scheme. What is the dispute about, exactly?

The heating circuit assumes both the presence of a tap on the bypass and its absence. Let's look at these 2 options:

with bypass valve:

without bypass tap:

If you surf the Internet, you can come across completely opposite points of view from both individuals and companies involved in the installation of central heating batteries.

If you look at the root, the problem is much deeper than it might seem at first glance. And it lies in the plane of affecting the interests of individuals and entire organizations.

Let's remember once again why a bypass is needed in principle. A bypass (aka jumper) is installed in front of the battery, providing an independent flow of hot water through your apartment. In a word, whether you have a battery or not, whether it is in good condition or bad, water must flow through your apartment, regardless of these factors, through the jumper.

Therefore, the fact that a jumper is needed is an indisputable argument. If, for example, you do not have a bypass at all, and only a battery is connected to the pipe, then this can lead to very unpleasant consequences:

- If the battery suddenly leaks, there is no way to stop the leak—the neighbors below are guaranteed to flood.

- If the battery suddenly gets clogged, then you block the entire riser, and your neighbors are left without water.

You can't argue against these arguments.

And then, regarding the bypass tap, whether it is needed, there is constant debate.

By the way, I will say that both options for installing heating radiators, which you saw above in the pictures, were made by 2 different licensed companies. Each has its own truth!

Bypass

Bypass (from the English words by (near) and pass (passage), bypass (shunt, bypass channel) - This is a bypass that runs parallel to shut-off valves, control valves, a direct pipeline. Bypass is used in various industries including medicine, the chemical industry, but We are primarily interested in its use in plumbing work and specifically the use of a bypass when installing heating systems.

The role of bypass in the heating system

To begin with, we will try to answer the question of whether a bypass is needed and what is its role in the heating system.

But before answering these important questions, let’s figure out what a heating bypass is.

Bypass for heating is a section of pipeline that runs parallel to the shut-off and control valves and transports (supplies) the coolant. That is, in short, a bypass in a heating system is a bypass pipe.

Bypass in the heating system, its functions and the most important and useful properties:

Economical. By reducing energy consumption

Performance. Bypass significantly increases the efficiency of the heating system

Fast system warm-up. By increasing the filling rate of the heating system (the emptying rate also increases), the heating system warms up faster.

Uniform heating of the heating system

Possibility to regulate the supplied coolant in quantitative equivalent

Ability to carry out repair work without shutting off or draining water

Basically, the bypass system is installed in convection and gravity heating systems in which there is no forced circulation of the coolant, since it most fully reveals its functions and allows you to correct a large number of shortcomings of heating systems without forced circulation, namely uneven heating of the heating system, the temperature at the boiler outlet differs significantly from the temperature at the inlet to the boiler (significantly higher than the recommended values), as well as low efficiency of the heating system.

The bypass system allows you to correct these shortcomings and eliminate the consequences of them, increase efficiency, uniform heating of the heating system is also achieved and at the same time significant savings are achieved, since coolant consumption is reduced.

We recommend installing a bypass in all heating systems, due to the large number of advantages and useful functions, and we believe that installing heating without a bypass system is a mistake made by master plumbers who offer installation of heating systems at low prices, but do not perform a large number of important works, presenting them as optional and additional. We consider this attitude of many private plumbers and craftsmen, as well as representatives of unscrupulous companies, to be incorrect and aimed at providing low-quality services at low prices.

Heating in people's understanding is all about comfort, it should not be hot or cold, but really comfortable, and this comfort can only be achieved with the help of highly qualified specialists, like the plumbers of our company, who will competently explain and advise you on all issues and help save money and provide really high-quality services.

If you want something cheaper, then remember the important function described above - efficiency; installing a bypass will naturally increase the cost of work, but only slightly, and the savings from a significant reduction in coolant costs will pay for these costs in the first months. At the same time, the quality of your heating system will significantly increase and all its shortcomings will disappear.

Is bypass necessary?

Whether a bypass is needed is primarily up to you to decide; in this article we tried to help answer this question. Our recommendations are that a bypass is definitely needed and this expense is not only important, but also self-sustaining.

Bypass valve

The bypass valve is usually installed instead of a tap and opens when there is a power outage (in the normal state it is closed) for natural circulation in the heating system.

Why do you need a jumper on the heating battery?

Find out the cost of repairs

Repair work?

Why do clients choose us?

Heating and Repair

We have the best prices!

On this page we can select the necessary parts of the structure for your apartment. Each factor has an undeniable role. Based on this, the selection of the listed parts of the system must be carried out technically competently. Installing heating for a mansion includes important components. The heating design has thermostats, air vents, a boiler expansion tank, a connection system, fasteners, manifolds, batteries, pressure-increasing pumps, and pipes.

Jumper to the heating battery

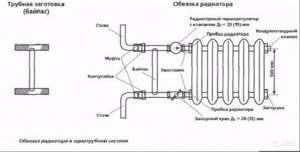

Let's consider why it is necessary to install a jumper (bypass) in front of the heating battery in a single-pipe distribution:

- It is needed when a minor accident occurs during the heating season. Then you can shut off the bypass and replace the leaking radiator, while the system will continue to operate. And after installing the new heating unit, open the jumper;

- If heating units with a large number of sections are installed, but the square footage of the room requires a smaller number, then it becomes necessary that not all the liquid circulates through the system.

If they want to replace an old cast-iron or steel battery with a new heating device, then they install a bypass and shut-off valves. The jumper allows you to control the temperature manually, and if a thermal head is installed, then the set heat for a specific room is maintained automatically.

Installing heating batteries with the installation of a shut-off valve and without a jumper is quite simple, but this scheme has a drawback. When the tap is turned off, the circulation of the coolant in the riser stops and therefore the heating system will turn off in the entire house, and after this your neighbors’ apartments will cool down.

If two taps and a bypass are installed in the system, it becomes possible (in the event of an accident - a radiator leak) to turn off the leaking device at any convenient time, without stopping the circulation of the coolant.

It should also be noted that the jumper on the heating battery is installed before the threaded connection.

In order to maintain a certain temperature in the room, a thermal head must be mounted on the battery.

All pipes and the lintel are installed inside the walls, and the taps (cut-off) and pipes remain outside.

The assembled radiator is subjected to hydraulic testing on a specialized stand. Using some special devices, the battery is connected to the press, it is filled with water and at the same time gas or air comes out of the device. In this case, the hydraulic press creates a pressure from 4 to 8 kgf/cm2.

If there is no leak, then the pressure gauge readings on the press do not decrease and the battery is considered to have passed the test.

If leaks appear, then the nipples are tightened and this eliminates them.

Next, the heating device is painted, but it is first treated with primer.

The installation of heating radiators can begin with both heating devices and the assembly of the riser.

If you start the installation from the riser, then if the connections are not accurate, you can only move the heating devices to the required distance relative to the windows.

Since sectional radiators are supplied from the manufacturer in an assembly of 6 or 8 sections, they can be grouped at the installation site. In this case, the number of nodes is either added or reduced.

It is important! To reduce the sections, the battery is placed on a workbench, and two radiator keys are installed at the required depth in the nipple holes (upper and lower), which are open at this moment. This work (unscrewing the nipples with keys) is performed by two people.

Next, the radiator is installed on brackets, having previously determined the distances from windows, floors and walls. Measurements are taken carefully and brackets are installed in the marked places, securing them with self-tapping screws. A radiator is hung on them, and then work is done to connect to the riser.

When replacing a heating battery, high-quality work is carried out, which should be done carefully and carefully, since the slightest mistake can lead to a lot of problems, such as a decrease in pressure in the entire heating system, a decrease in coolant temperature and others, which will lead to the neighboring apartments not warming up .

Therefore, before starting work on dismantling the old and installing a new heating system, read the instructions and recommendations of the manufacturers, and if you cannot do this work yourself, contact a specialist.

(No votes yet)

Jumper to the heating battery

To install a valve after the jumper and shut off the battery when it’s hot, water will then circulate through the jumper.

afrikapilot

Enlightened (40232) 3 years ago

If you have shut-off valves in front of the battery, then when you turn off the valves (to change the radiator or to eliminate a leak, etc.), you only shut off the supply to the radiator, and the riser will continue to work.

ANTigona

Oracle (66526) 3 years ago

So that, in case of problems with your battery, it can be repaired without disconnecting the entire riser. But it can only be closed in emergency cases.

to increase system throughput. If you use modern batteries, you can throw out these jumpers

Natalia Kryachkova

Student (126) 3 years ago

The diameter of the jumper must be smaller than the main pipe

Evgeniy Vshivkov

Thinker (8927) 3 years ago

With the lower distribution from the supply, the riser rises to the top and falls down to the return. It is into this riser that the batteries crash in parallel. But everyone thinks this way: I’ll cut off the jumper and it will become warmer. This is a huge mistake. I am now seeing the same picture in my daughter’s house. If the coolant overcomes only the resistance of the riser pipes and the static resistance of the water, then the riser going up and down warms up relatively evenly, as a result, hot water reaches the radiators on all floors and everything is fine.

If you pass the coolant through the batteries, the line resistance increases, the speed of the coolant decreases and heat transfer deteriorates for everyone.

As a result, a cunning tenant, even on the 1st floor, will receive a more or less hot battery on the supply and a cold one on the return, he made a mess for himself and then let’s screw the boiler house and the management company. That's about it. Well, other technical wisdom:

Types of bypasses

There are several types of bypasses for use in heating systems.

Unregulated

It is made in the form of a bypass jumper . There is no shut-off and control valve (faucet or check valve) on the jumper.

Operating principle

- Part of the hot HP passing through the bypass is mixed with the flow at the battery outlet and increases the temperature of the HP entering the input of the next battery.

- If the heating device fails, the HP flow bypasses the battery, maintaining circulation.

Peculiarities

- When installing vertically, the diameter of the bypass is one step smaller than the diameter of the supply pipes.

- With horizontal wiring, the diameter of the circuit coincides with the supply pipe, and the diameter of the branches up the battery is one step smaller (the heated HP tends upward).

- Install as close to the battery as possible (next to the shut-off valves).

Manually controlled: what is it?

, either a ball valve is installed on it to shut off, or a three-way valve is installed at the intersection of the bypass and the supply pipe to the radiator.

Operating principle

The three-way valve has three positions:

- closes the bypass and directs the entire HP flow to the radiator;

- closes the supply to the radiator and opens the bypass for the HP flow (position for repairing or replacing the radiator);

- opens both paths for the transformer: to the battery and along the circuit.

Peculiarities

- A valve on the bypass next to the battery is usually installed to close the jumper when the radiator is not heating well. But such a solution is technically illiterate - the flow through the bypass is approximately equal to the flow through one section of the radiator, so a significant increase in the temperature of the battery will not occur.

- In a private house, a ball valve is installed in parallel with the central pump on the return pipe. The valve is closed when the pump is running, and opens manually when the pump fails or when it is replaced to restore circulation.

Attention! It is prohibited to install a valve on the radiator bypass in an apartment building with a single-pipe system . It can lead to disruption of circulation and reduced temperature of the coolant entering neighboring apartments.

Automatic, like working with a pump

Installed in parallel with the central station . A check valve is mounted on the shunt pipe to automatically restore circulation through the bypass when the central pump is stopped.

Operating principle

A bypass with a differential (ball) valve is installed in parallel with the central heating unit on a vertical coolant supply pipe from the boiler .

When the pump is operating, part of the flow presses the rubber ball against the funnel and closes the passage of the HP through the shunt pipeline.

When the pump is turned off, the ball rises under the pressure of the HP flow through the supply pipe and opens the passage for the HP through the bypass.

A bypass with a petal check valve is installed parallel to the pump on a horizontal return pipe (in a gravity system). The valve shutter (petal) is pressed against the seal under the action of the flow from the pump, closing the bypass. When the pump stops, the petal moves away from the seal (opens) under the influence of return hydraulic pressure, restoring circulation.

Important! It is necessary to periodically check the operation of the check valve so that it does not become clogged with deposits and dirt.

The check valve is usually mounted on the main pipe (supply or return). The bends from the main pipe to the central pump are made two sizes smaller in diameter.

About responsibility for installing a bypass valve

Having received a dozen complaints, representatives of the housing maintenance service will come with an inspection and quickly discover the problem. The apartment owner will be required to correct problems in the system at his own expense. It is quite possible that the fault for the low temperature in the batteries lies with the housing office itself or the company providing technical repairs. But all accusations will be directed towards the person who installed the tap on the bypass, disturbing the thermal balance. If several people install such taps, this will lead to a heating collapse. The whole house can be damaged. The design of some multi-storey buildings assumes the following: the coolant can rise in one riser, pass along the technical floor, and fall in another, thus continuously circulating. By placing a barrier at one point in the system, the tenant disrupts the thermal balance in two risers at once. Another riser may well be located in the same apartment. The result will be the following situation: one battery, located in the living room, heats better, the other, located in the next room or kitchen, heats worse.

Step-by-step instructions for installing a bypass

It is advisable that the heating system, including bypasses, be installed by specialists who can correctly calculate everything, carry out installation, commissioning and pressure testing in accordance with the rules and regulations provided for in this area of construction. However, if you think that you can handle everything yourself and are 100% confident in your strength, then you should read the installation instructions.

The most important thing at the initial stage is to make a competent calculation of the bypass. Then you will need to purchase ready-made structures or make them yourself. For those who are making a heating system for the first time, it is better to use the first option. This will reduce the likelihood of error to almost zero, since the finished parts are already designed for a particular pipe and you won’t have to rack your brains. Once you have decided on the type of equipment and purchased everything you need, you can begin installation.

The most important thing to remember is that the bypass is never installed on the riser. It should be shifted closer to the heating radiator by at least 2/3 of the length of the pipe. There is also no need to make a bypass close to the battery, as this will cause it to overheat and change the flow parameters, which will destabilize the entire system.

You cannot install a valve or gate valve on a valveless bypass. For all its convenience, this solution violates the rules for using heating in apartment buildings, since it is prohibited to install additional elements on the risers that could change or disrupt the flow of liquid. After all, this is a complex system in which even the slightest changes in parameters can disrupt its performance. The narrowing of the bypass diameter relative to the rest of the pipeline must be calculated correctly, so that there is no fear of a decrease in the heating capacity of the radiators.

Bypass device

The bypass operation begins with the activation of the pump, which pressurizes the system. In a certain section of it, when it reaches the desired value, a specially designed valve opens and redirects the coolant flow in the desired direction. As soon as the pump stops working, the valve closes the hole in the pipe. The bypass can operate not only in forced, but also in natural coolant circulation without consuming electricity.

There are two varieties of it:

- Manual

. A simple version of its implementation without additional devices. - Automatic

. It is equipped with a check valve. A circulation pump is sometimes built into the system with it, which regulates the coolant flow.

When choosing the design of the device in question, you need to consider where it will be installed. The following options are available:

- When installed on a radiator, it is a jumper with two ball valves.

- Installing a device to regulate the temperature in a room involves the use of thermostats.

Installing a bypass assumes that the heating system will have a pump, two taps, a filter and a check valve. The backup node can work either continuously or only after it is turned on.

What regulates the bypass of the TIM JH-1036 mixing unit.

The mixing unit has a conditional mixing chamber through which the underfloor heating circuit and the boiler heating circuit pass.

Typically, a heated floor mixing unit has one adjustment parameter - the water temperature in the heated floor circuit. The TIM JH-1036 mixing unit also has some kind of bypass, and even adjustable. And this is not the bypass balancing bypass, which is triggered by excessive pressure developed by the pump.

The pressure balancing bypass can be seen in the photo - the rightmost personal belongings.

I need it because it is possible to block all heating directions of the heated floor as a result of automatic regulation. By the way, I still haven’t figured out how to regulate the balancing bypass TIM M307-4 - maybe someone can tell me.

As for the mixing chamber bypass, you can find the following graphic explanation of the operation of the mixing unit bypass:

Little is clear from these diagrams.

Moreover, it is not clear what the numbers on the scale mean and what the current value is tied to. All this can be found out only by holding the TIM JH-1036 mixing unit in your hands:

It turns out that the adjusting screw turns the cylinder, which has a slot that closes when turned. Through this slot, water can be pumped by a circulation pump, bypassing the conditional mixing chamber.

The maximum opening of the slot (pictured above) corresponds to setting the adjusting screw to position 5 (pictured below).

The technological ledge on the mixing chamber body can be taken as a conventional point for reading the scale value. When the scale value is 0, the gap is maximally closed. In this position, all the water pumped by the circulation pump along the contours of the heated floor passes through the mixing chamber.

With the bypass completely closed, the thermal power of energy taken by the mixing unit from the heating system is maximum.

If the bypass is completely open, then part of the water circulates through the heating circuits without entering the mixing chamber - and the thermal power of extraction is minimal.

But in practice it turned out that not only thermal power is regulated by the bypass.

Pump types and bypasses

When installing this device, you need to pay attention to the type of pump that is used in the heating system. The unit is installed on the main highway.

There are two types of pumps:

- "Wet". In this type, the rotary impeller is arranged in water. The wet type pump can be installed on the return and supply pipes.

- "Dry". The rotor in such a pump does not come into contact with the coolant. The disadvantage of a dry type pump is noise during operation. Therefore, it is advisable to use it in a boiler room with good sound insulation. The unit can be installed on the return pipeline.

How does the bypass of the TIM JH-1036 mixing unit affect the system.

It would seem: we set the thermal power of the mixing unit to maximum, completely closing the bypass slot - and that’s it.

But the flow meters of the underfloor heating collector make it possible to find out that not only the thermal power is regulated by the bypass. When the bypass is completely closed, the floats of the flow meters float up sharply.

It turns out that the water flow through the heating circuit with a completely open bypass is more than twice as much as with a completely closed one.

This is not surprising - pumping water through the mixing chamber requires pump power, which affects the speed of water flow.

At maximum thermal power of the mixing unit, the flow rate of water along the contours of the heated floor is minimal. To uniformly heat the entire underfloor heating circuit, it may be necessary to turn on the pump at second speed, which will increase the noise of the heating system.

It turned out that in my system the minimum thermal power of the mixing unit is sufficient to ensure a coolant temperature of 32 degrees at the supply manifold with all directions of underfloor heating open, even when starting a cold heated floor.

But in other cases it may be necessary to increase the selection power.

Bypass assembly

The bypass is a section of the main pipeline between the heating boiler and the working circuit. In this section of the direct current, a ball valve is installed, which, when the supercharger is turned on, blocks the movement of the coolant. A less practical solution is a shut-off valve, the normal position of which is closed when the system is running.

The pump is installed in parallel, by means of two branches, embedded in the main pipe and directed towards each other. For fastening, you should use quick-release fittings of the “American” type, which will allow you to quickly dismantle it if necessary. As the fluid moves, a coarse filter is installed in front of the supercharger, and on both sides this design is limited by shut-off valves. The diameter of the pipes must correspond to the inlet and outlet openings of the pump.

Often the best solution is to buy a ready-made bypass assembly. Manufactured for pumps of various diameters, they are already equipped with all the necessary shut-off valves and filter. All you need to do is install it in the desired area of the heating system and install the pump. The key parameter is the distance between the fittings. For the most common type of circulation pumps, it is 110 mm.

How does the bypass work under normal conditions?

From the top floor, coolant is supplied through the supply pipe to the bypass installation point. As we know from physics courses, both electric current and liquid always move in the direction of least resistance. If water gets from a 3/4-inch diameter pipe into the section leading to the battery, it will be easier for water to penetrate into the larger diameter pipe. Therefore, only a small part of the coolant enters the bypass with a diameter of ½ inch, the rest of the pressure moves into the battery through a pipe with a diameter of ¾ inch, then it passes through the taps and thermostat and goes into the battery registers. After passing through and partially cooling, the water again exits through the ¾-inch pipe into the main line, and passing through the shut-off valve, it connects with the flow from the bypass and moves further in the general flow. At normal pressure and high temperature, the temperature loss in this area will be insignificant, unless the apartment owner has installed an additional three-meter air-flow battery.

In the event of an emergency situation, for example, depressurization of the radiator for repair work, an emergency shutdown of the branch to the battery is performed - the taps on the supply and outlet pipes are closed. This is where the bypass comes into play. The coolant, coming from the upper floor, moves along the only possible route - through the jumper and further along the pipe to the lower floor. Thus, the jumper allows you not to disconnect the entire riser from the coolant supply, which allows you to correct the situation with the least losses and in the shortest possible time.

"Small circuit" in the heating system

Here, the bypass is a section of pipeline that connects the supply and return lines through a three-way valve.

The principle of operation of the jumper in this application is simple: after turning on the boiler, the valve prevents cold coolant from the heating circuit from entering the boiler. After the coolant has warmed up to the required temperature (often 45-50°C), the valve opens and begins to mix hot water into the return pipeline, thereby preventing the appearance of condensation in the combustion chamber and on the heat exchanger of the solid fuel boiler.

And as a conclusion: a bypass pipeline is a necessary, simple and practical element that allows you to use CO with maximum efficiency while significantly reducing energy costs. In practice, this looks like reducing the volume of water supplied to heating devices while maintaining their calculated heat output.