Specifications of induction heating boiler

Boilers powered by electricity are in great demand among consumers. Thanks to this, new variants of their design and operating principles are appearing on the market. Similar ones include electromechanical boilers, which operate on the basis of a similar physical phenomenon, such as electromagnetic induction of current in conductors. This achieves a high efficiency factor.

Advantages and disadvantages

Electromechanical heating boilers are now one of the most common options for heating residential premises.

This was achieved thanks to the positive qualities:

- High efficiency and, as a consequence, low energy consumption.

- If desired, the boiler can operate at low pressure and from different types of current: continuous, alternating.

- Lime resistance. This is caused by the structure of the boiler.

- Financial savings, since such a device does not stop working faster by an average of 25%.

- There are no detachable type connections in the design, so you don’t have to worry about leaks.

- There are no components that can wear out. The period of validity is long: about 30 years.

- This boiler can work together with other systems: wood, gas, etc.

- Water may not be the only type of heat carrier. It is possible to use antifreeze or oil.

- There is no need for a separate room with ventilation. It is also worth saying that you can install it yourself.

Apart from everything else, the induction boiler also has a lot of disadvantages:

- The very first thing is the price. For example, SAV 5 kW with a price of about 40 thousand rubles, and Protherm Skat 6 kW about 23 thousand rubles. Quality always implies preferable cost.

- Secondly, these are the dimensions of the unit and its weight. The smallest boiler weighs at least 20 kg, so it is often installed on the floor.

- Third, if you install the device in a house with 2-3 floors, you will need a circular pump of good power.

Advantages and disadvantages

Induction heating boilers are currently one of the most popular methods of heating residential premises.

This is achieved thanks to the following advantages:

- High efficiency and, as a result, low energy consumption.

- If desired, it is possible to operate the boiler at low pressure and from different types of current: direct, alternating.

- Lime resistance. This is due to the structure of the boiler.

- Cost savings, since such a unit works faster by an average of 25%.

- The design does not have detachable connections, so you can forget about leaks.

- There are no elements that can wear out. The validity period is long: about 30 years.

- This boiler can operate in conjunction with other systems: wood, gas, etc.

- Water may not be the only type of coolant. It is possible to use antifreeze or oil.

- No separate room with ventilation is required. In addition, you can install it yourself.

You can read about antifreeze for the heating system in this article.

In addition to all this, the induction boiler also has a lot of disadvantages:

- Firstly, there is cost. For example, SAV 5 kW costs about 40 thousand rubles, and Protherm Skat 6 kW costs about 23 thousand rubles. Quality always means a good price.

- Secondly, these are the dimensions of the unit and its weight. The smallest boiler weighs at least 20 kg, so most often it is installed on the floor.

- Thirdly, if you install the unit in a house with 2-3 floors, you will need a circulation pump of good power.

Working principle

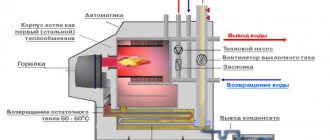

A common example of this is a coil that is wound on a dielectric pipe. A steel core must be installed in the middle. An electric coil will warm the pyron.

All that remains is to connect it to the main line with the heat carrier, and such an “induction boiler” will begin to supply heat.

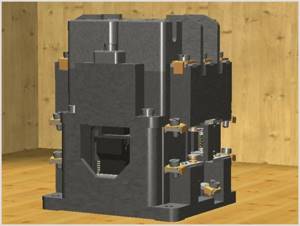

Hotmer induction boiler design

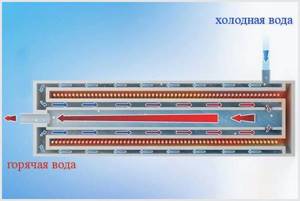

Electromechanical boilers are perfect for heating a private home. The boiler operates by using a coil based on the principle of an induction cooker. The inductive coil produces a magnetic field.

Heat moves from the heater to the liquid heat carrier through a labyrinth of iron tubes without leakage.

The strength of the current acts to change the strength of the magnetic field in the device. This is how the house is heated.

After placing a core in the middle of the coil, Foucault eddy currents appear, which affect the electrical resistance of the metal. There is a temperature increase on the surface of the tube system.

Principle of operation

A simple example of this is a coil that is wound on a dielectric pipe. A steel core needs to be installed inside. An electric coil will heat the metal rod.

All that remains is to connect it to the main line with the coolant, and such an “induction boiler” will begin to supply heat.

Hotmer induction boiler design

Induction boilers are excellent for heating a private home. The boiler operates by using a coil based on the principle of an induction cooker. The inductive coil produces a magnetic field.

Heat moves from the heater to the coolant fluid through a labyrinth of metal tubes without leakage.

The strength of the current affects the change in the strength of the magnetic field in the device. This is how the house is heated.

After placing the core inside the coil, Foucault eddy currents appear, which affect the electrical resistance of the metal. There is an increase in temperature on the surface of the tube system.

Overview of manufacturers and models of induction boilers

For you, we have prepared a review of manufacturers of induction heating boilers, as well as some of its models.

It has a lot of models and thanks to this it provides a wide choice for the consumer. The power of VIN heating boilers can be from 3 kW, the heating area can be from thirty meters, the initial cost is from 32,000 rubles.

The VIN company's models are called vortex models. Their difference is in the power supply: the first winding, which is already converted and high-frequency, the electromagnetic field strength increases due to Foucault currents. The specificity of the manufacture of the boiler body and heat exchanger is also taken into account. To make them, ferromagnetic alloys are used.

Let's look at the specifics of boiler models from this manufacturer in the table.

The characteristics of the SAV heating boiler are ease of use and installation, environmental friendliness, automatic operation, durability. In fact, there is no possibility of scale formation, and there are no parts that move and are subject to wear.

SAV models have their own operating specifications. The first winding of the induction heater is supplied with an industrial voltage of 220/50 from the boiler transformer. The second winding is performed in a closed loop. Liquid moves through it. It is considered part of a heat exchange apparatus in which the thermal fluid of the heating system is heated. Apart from water, antifreeze may also be suitable.

Since the current quickly increases the temperature of the circuit, the efficiency of all boilers is the highest.

The disadvantages of the SAV induction boiler include the high price. The price of boiler models of this type ranges from 32,950 to 65,000 rubles. Two more disadvantages are dependence on the network and the difficult process of power adjustment.

There are many models from this manufacturer. They stand out for their high productivity. The power range is from 4.5 to 250 kW, and the efficiency can reach 98%.

The "Geyser - 5" model requires a mains voltage of 220 V, the other key models (10, 15, 20, 25, 50, 100, 250) - 380 V.

The uniqueness of this model is its reliability, as reviews say. These boilers are resistant and have a second class in electrical safety. They do not require special maintenance, and due to the absence of combustion products, there is no likelihood of harm to health. Geyser boilers are distinguished by their small size, thanks to which the device can be installed in a small space. The model does not stop working quite quietly, thanks to this the owners do not need to use materials for sound insulation.

As a minus, we can highlight the difficult installation and connection of the Geyser boiler. All models of induction heating boiler require 380/3ph. As a rule, only boilers with a low power of 220/50 will work from the network.

This brand is used for heating residential premises, as well as industrial, administrative buildings, etc. Its models are different (4.7; 13; 22; 50; 100; 250; 500). This induction boiler is used in closed heating systems. Basically, it uses water as a coolant. The heater operates “automatically”, but if you wish, you can change the operation of the heater either according to the temperature of the coolant, or according to the air temperature in the building.

The Edison boiler has more positive parameters than negative ones. Its advantages include a long service life, high electrical and fire safety, and also unchangeable efficiency during operation. It is also worth saying that when purchasing this boiler, you will not need to regularly monitor it and always operate it.

More certain properties of the Edison heating boiler:

- current frequency 50 Hz;

- the highest coolant temperature in degrees – 115;

- the weight of the equipment varies from 40 kg (“Edison - 4.7”) to 1500 kg (“Edison - 500”).

- use (with the consent of the manufacturer) of various thermal media, for example oil, water, antifreeze.

A number of models of these boilers have a power ranging from 6 to 30 kW and are also suitable for heating industrial and residential premises (up to 350 m2).

Here are some other properties:

- The efficiency of the Miratron heating boiler is 90%;

- excellent protection against scale;

- proper use of energy and saving the client money;

- connection to any type of electrical network;

- does not stop working very quietly and does not ask for continuous supervision;

- work only with closed heating systems;

- the use of an inverter contactor in control and, as a consequence, the high price of the equipment;

- large weight and dimensions of the boiler.

The cost of the Miratron heating boiler varies. For example, model “Miratron A006” with a power of 6 kW, heated area of 70 m2? and weighing 50 kg has a price of 45,000 rubles. "Miratron A006" with a power of 15 kW, a heating area of 170 m2? and weighing 80 kg – 65,000 rubles.

Comparison of fashion models

Let's compare many models from different manufacturers of induction heating boilers with similar parameters.

Customer Reviews

Customers have different opinions about the performance of new generation induction boilers. I would like to highlight that these boilers are very popular and will win the trust of consumers. After all, the variety of models and their manufacturers makes it possible to choose a device that is suitable for a home or room with a certain area and other specific parameters.

Electromechanical heating boilers have a high efficiency, which means they make it possible to save several times more by reducing the use of electricity. And this is their key advantage. All clients note the pros and cons of specific models. We wrote above about the advantages and disadvantages of induction boilers.

More points on which consumers choose when choosing induction heating boilers:

- First of all, there are no emissions of polluting products into the atmosphere during their operation.

- Secondly, there is no need to allocate a separate room for storing solid fuel reserves.

- Third, high electrical and fire safety makes it possible not to worry about accidents.

An induction boiler will work simultaneously with heating devices using other types of fuel, and heated floors can also be connected to it.

If you are going to buy an induction electric heating boiler, then read the following tips.

- To begin, carry out a thermotechnical calculation of heat loss in the room.

- Check the number of phases, because single-phase boilers can be connected to an outlet, but three-phase boilers require an individual power line.

- Then you should think about how the boiler will work, and specifically what power is best to choose the device. If, for example, it is needed only to maintain a stable low temperature, then a power of up to 6 kW is absolutely sufficient.

- If you are ready to “invest” a little more money in a new acquisition, then sellers are ready to offer you the opportunity to purchase a remote control unit, a mode programmer, or something else.

Decide for yourself which induction heating boiler to choose. Now you know about all the pros and cons of many models, as well as the working principle of similar units.

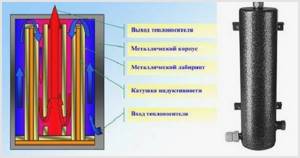

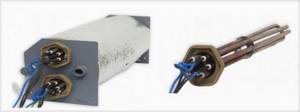

Induction boiler device

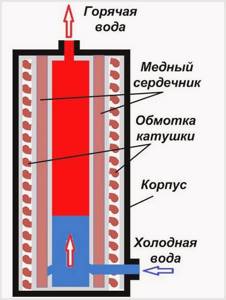

Induction boilers take advantage of the fact that an iron core placed in the middle of an inductor coil is quickly heated to high temperatures due to induced Foucault currents. The TEN of such units is a powerful inductive coil, which is hermetically sealed into a large and heavy metal case, which is also the core. Water or the rest of the coolant, washing the TENA body, heats up and then enters the heating system. There are two types of induction heaters, which have certain differences:

Induction boiler device

- Vortex electromechanical heaters VIN (Vin). Before applying to the primary winding of the inductor, the 50 Hz network current is converted into high frequency. This achieves an increase in magnetic intensity and induced Foucault currents, and the heating temperature increases. In such boilers, not only the secondary winding is made of ferromagnetic alloys, but also the housing, which increases the heating area and makes it possible to heat the coolant faster.

- Induction heating boiler Sav. Boilers of this type use a secondary winding as a heat exchanger, which is made like a labyrinth with thick walls (to increase the heat transfer area and better heat the coolant). Since the conductor is in an alternating field, the coil will additionally generate reactive power.

How does an inverter heating boiler work?

As a rule, if we consider classic electric boilers, then the principle of operation is that energy is transferred to the coolant using a heating element. So, if the design has a heating element, then it is also necessary to provide a separate place to heat the water, protect the heating element from the corrosion process, and also take into account heat loss.

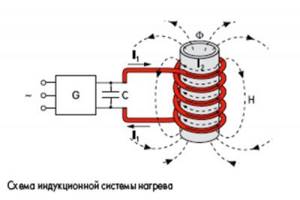

Inverter (or induction) heating boilers operate on the principle of electromagnetic induction.

Thus, with the help of an alternating magnetic field, an induction current is generated. In order for this process to be implemented, direct current from the electrical network must be converted into alternating current. This is what the inverter does - it can work both from the network and from batteries.

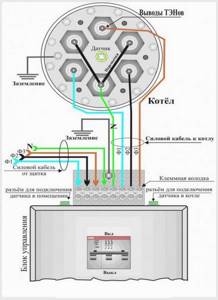

Operation diagram of an induction heating boiler

So, an inverter heating boiler has two circuits:

Search the site otoplenie-doma.org

- Magnetic. Generates an alternating magnetic field.

- Heat exchanger. Heats up the coolant.

When alternating current is applied, the coil creates a magnetic field, which heats the water in the pipe system.

Electromechanical heating boilers: advantages and disadvantages

This equipment has many positive features:

- Greater reliability. If there is automation, they work independently and do not require strict control and the mandatory presence of a person. As a rule, only one situation is possible that will lead to failure of the boiler: in the absence of a coolant in the system, the body-core becomes especially hot and can melt. Therefore, in heating systems with an induction boiler, it is necessary to control the level of coolant in the system.

- Any thermal medium can be used. An induction electric boiler doesn’t care about heating, as long as it’s a liquid.

- The efficiency of this equipment, like any type of electric boilers, is above 90%. The specific figure depends on the design of the heat exchanger and other design properties of a particular model.

Induction boiler device

- Long operational period. With adequate operation, such equipment can last 30 years: there is nothing to burn, since the inductor is hermetically sealed in the housing and isolated from contact with the coolant. The coils are not wound closely and are filled with a specialized compound for protection, so the likelihood of breakdown of the coils is also low. There is nothing else that can break in induction boilers.

- normal installation and maintenance. A household heating unit of this type is a small squeegee, sealed at two ends. There are two fittings on the body for connecting the heat carrier supply and return, and there is a cord for connecting to the automation. Now everything can be said. Connecting it is really simple. The lowest-power boilers have a length of a couple of tens of centimeters, so they can be placed under a window, behind a door, or simply to replace one of the sections of the pipe. There is one subtlety: if a system without pumps is used, then the boiler can only be positioned vertically.

- Greater heating efficiency. An electric induction boiler has low inertia, due to which heating of the coolant begins almost immediately after switching on. The boiler also turns off quickly.

- Scale does not appear on the heating element. This happens for certain reasons. First of all, the core vibrates all the time, so nothing can be deposited on it. Secondly, the temperature of the coolant does not rise above 90 o C. Third, the system is closed and the amount of coolant is limited; it is also worth saying that you can use compounds that simply do not produce deposits. In general, it is a fact that there are no deposits in the boiler.

Induction heating boiler takes up very little space

These are undeniable advantages. There is another one that causes too much controversy. Sellers of induction boilers say that they are more economical than classic heating elements. And they even call savings - 30%. This is where there are frequent debates. In theory, for a boiler to provide 10 kW of heat, it must also consume 10 kW of energy (electricity). Even a little more, since the efficiency is not 100% and there are still losses. And regardless of the method of heating the coolant.

As a rule, everything is like this. No one has repealed the law of conservation of energy. But reviews from owners of such stakes indicate that there are actually savings, and they pay less for electric heat supply. What could be the matter here? The fact is that the system is controlled automatically, and it turns on the boiler exactly when it is necessary to raise the temperature of the coolant. And since the system has low inertia, less electrical energy is wasted. However, these are positive qualities, mainly, of automation. Although the fact remains: there are savings.

Electric electromechanical boilers are used not only for heating the home, but also in production

Now about the cons. There are not many of them, but they are significant. And the most important thing is the high cost of equipment. There is nothing to say here - this equipment is actually expensive. It is at least twice as expensive as heating element boilers. But the lion's share of the cost comes from automation. From what is described above, it is clear that the better the automation works, the more economical and durable your heat supply will be. It is also worth saying that today certain companies recommend such additional functions as remote work management. A very beautiful moment, especially for those who are often away. For a certain period of absence, you can set a low temperature (5-10 o C), and upon arrival, raise it to a comfortable level. Both comfortable and practical. There is also a rather significant drawback, but it is common to all electric boilers - if there is electricity, there is heat supply, if not, we freeze. An option to solve this problem is diesel generators and uninterruptible power supplies.

There is an additional disadvantage: from my own operating experience, many models of induction electric boilers are very noisy during the operating period. But this cannot be attributed to all models, but only to some of low cost. An alternative solution is to take it to an individual isolated room.

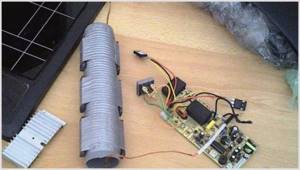

Is it possible to make an induction boiler with your own hands? As a rule, it is possible. But you will not be able to find the correct calculation and detailed diagram of the boiler, indicating the indicators of all elements. Choosing on your own is long and very difficult. It’s not for nothing that these boilers are expensive - in order to achieve the highest efficiency and low consumption, a remarkably balanced circuit is needed. It is required not only to organize the heating of the housing, but also to calculate at what speed and in what volume the liquid should circulate in order to avoid overheating. It is also worth saying that you will need automation, there are also a lot of worries with it. The equipment is very technologically advanced and its independent development is problematic.

Kinds

Inverter electric boilers are:

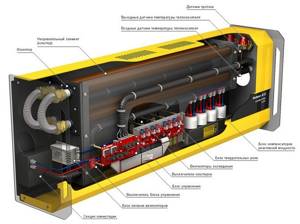

- Industrial. They are large in size, which is due to the volumetric heat exchanger . In addition, they use a complex system for converting electric current and a cylindrical winding. Of course, the power of such units is very large.

- Household. They are designed for heating houses. They include a toroidal coil, which can receive electricity not only from the general network, but also from batteries . The sizes are small.

Electromechanical boilers: manufacturers and reviews

Despite the fact that induction heating equipment has been actively promoted on the market not so long ago (16-17 years), there are quite a lot of offers. There is a lot to choose from. Here are a couple of companies whose equipment is of constant interest.

Induction boiler "Miratron"

Induction boiler "Miratron"

Boilers powered by electricity of the Miratron induction type are produced with a power from 9 to 30 kW. There is the possibility of stepwise power adjustment, price from 45t.r. (9kW boiler). There are few reviews about Miratron induction boilers. A homeowner on 150m2 heats his house with a 15kW boiler from this company. He notes the fairly silent operation of the equipment and also speaks about the economy of the system: 15 kW is turned on exclusively to overclock the system, sometimes 9 or 6 W are used for support. For the system to work efficiently at his home, the power of the built-in pump turned out to be too small, so it was necessary to install 1 more.

The system of equipment building modules is noted as a good point: there are several low-power heaters that are turned on/off if necessary. So even if one breaks down, the house is not left without heat. On the other hand, such a design entails rather large dimensions: 400x1600x300mm is the smallest of the boilers.

Electromechanical boilers "Geyzer"

Geyser boilers can be used for individual heating of houses, cottages, workshops and industrial premises. Electrical safety class – 2nd (does not require protective grounding). Power – from 4.5 kW to 250 kW. The characteristic of such boilers is that only the lowest-power “Geyser -5” does not stop operating from 220V, all others are on 380V networks. They are produced in 2 types - “Geyser E” - for systems with a storage tank, “Geyser B” - with a heat exchanger. They have a traditional design for this type of equipment - a bend sealed at the ends.

Electromechanical boilers "Geyzer"

Edison induction boiler

Edison boilers are produced at the Siberian Innovative Automotive Manufacturing Enterprise. Can only be used in closed heating systems. The declared efficiency is 98%, the power indicator is 0.99. Available in power ratings from 4.5 kW to 500 kW.

The existing reviews can be summarized as follows: the equipment is reliable and economical, and does not often require repairs. Sometimes thermal converters break. Reviews are mostly from the heads of companies from a wide variety of regions and various areas of economic activity. But they all agree on one thing: the use of this type of boiler (used both for heating and in technological processes) is economically reasonable and reliable.

Edison induction boiler

Electromechanical boilers PIN

Electromechanical boilers PIN

Flow-through electromechanical heaters PIN are products made in Ukraine. Warranty period – 36 months. PIN electromechanical boilers are produced with a power from 3 kW to 50 kW, the declared efficiency is 97-98%. The delivery set includes a control cabinet in which the automation is located, an external water thermostat, a digital indicator on which the current and set temperature of the coolant is displayed. Optionally equipped with a contactless control panel and a thermostatic valve. Imported control equipment can be installed (upon request).

In reality, it is still difficult to say how good or bad these boilers are. But the thing is that the processes that are associated with induction have not been sufficiently studied, and it is currently unrealistic to calculate them. That is why there are no clear conclusions about the effectiveness of induction boilers. The equipment does not stop working and heats up, but how the savings are achieved (and judging by impressions, they still exist) is unclear. Whether to use it or not is up to everyone to decide for themselves. Only one wish - if you have operating experience, leave your own impressions: it will be easier for your “followers” to look and make decisions.

Advantages

The inverter boiler has the following advantages:

- Ability to work with any type of coolant. That is, it does not matter whether water or antifreeze circulates through the heating system. For comparison, it’s worth remembering electrode electric boilers. They can only work with water or a liquid that is electrically conductive such as water. Antifreeze cannot be used in them.

- The heating inertia is low. This means that the water or other liquid heats up quickly. The nice thing is that you can speed up heating by using a centrifugal pump.

- Long service life. The first elements that can fail are electrical. At the same time, the coil, automation or inverters for the boiler work for a very long time. It is worth adding that this plus is also the result of the fact that the heating element (induction coil) does not come into contact with the coolant, because the coil is isolated from the liquid. Over time, the walls of the water tank may become dirty , but this only occurs if the procedure for filtering water before filling it into the heating system is neglected.

- The possibility of depressurization of the case is almost zero. Therefore, there is no point in worrying about possible leaks.

- High fire safety. Solid fuel and gas boilers are very far behind in this regard.

- Quite a weak noise.

- The efficiency is almost 100%.

- Small sizes. They are significantly smaller than gas or solid fuel units. True, inverter boilers have more characteristics than similar electric boilers.

- This cauldron is easy to make with your own hands.

Electromechanical or heating element heating boilers for a private home - comparison and which is better.

An induction heating boiler powered by electric power is still perceived by many as a technological product that should help significantly save your cash.

However, by and large, this is a marketing technique of marketers, which the majority believed in and in the end did not receive any savings.

- big sizes

- Difficulty in working when connecting additional equipment (storage electric water heater)

Manufacturers loudly advertise their merits, but if you think carefully about them in detail, even they seem very dubious.

How do advertisers communicate these benefits? They almost always compare it to a heating element boiler. Since they directly occupy 90% of the electric boiler market.

At the same time, the disadvantages (real or imaginary) for equipment with a tubular heater are highlighted, and the positive qualities are given, which are not even close to similar in induction ones. And this means they are better.

Let's go through these disadvantages and advantages in detail.

The first is in an induction electric boiler, as if there were no heat. But in a heating element, sometimes there are more than a dozen of them, which means there is a high probability of them malfunctioning, maybe several at once.

However, if there were no TENA, then how would the boiler heat the water? A similar coil essentially plays this role, only without contact with the liquid. Thanks to this, this component is present in any such unit.

But as for the high probability of tubular-type heating elements failing, this depends on the product and manufacturer that you purchase.

There are professionals who have installed more than 500 heating element boilers over the years of their own work, and have not changed a single element under warranty during this entire period.

The second disadvantage when comparing is a considerable number of sealing connections (tubular-type heating elements, flanges) and their complete absence in an induction boiler. Here these pros and cons can even be swapped.

After all, if the tubular type heating element does break, you can easily replace it. Or simply remove it from the circuit for a short time, install jumpers differently and continue working.

But if the coil burns out (due to an interturn short circuit), how much will the repair cost you? And will you be able to keep warm with a similar malfunction in the future?

3rd point - with poor water preparation and excessive load, scale appears on the surface of the TENS. In induction, scale is excluded.

First of all, the same scale that many imagine, based on the example with the kettle, is not found in heating systems. Because the liquid does not boil there.

But deposits undoubtedly exist everywhere and always. Moreover, in a variety of systems - gas, heating elements, wood, induction, etc.

“scale” in a gas boiler

These are actually the impurities that are present in the water mass anyway. Pour water into a clean glass, let it evaporate and you will be able to see a thin film on the walls.

Terminal contacts in heating element models, and a significant part of them, as a rule, are in the temperature difference mode. Heats up at the highest load, and cools down when turned off.

And this creates obligations for their revision and tightening.

And in induction, there seem to be no electrical contacts. In reality, they exist everywhere and always, including in induction ones.

However, as for the former, copies with high-quality screw clamps have now begun to be produced.

Or there may be screw-shaped connections with a locking washer that do not require maintenance, or spring clamps that also go without control and revision for years.

These are practically imaginary advantages.

The service life of tubular-type heating elements depends on the quality of the coolant. As “comparators” assure, this is only 1000 working hours if you do not take action and soften hard water. Well, if they softened it, then about 5000.

When using such data, the heating and water supply systems are confused.

This may apply exclusively to DHW or main heating. There, the operator of the heat generating installation cannot trace water leaks.

If we are talking purely about your home, where everything is assembled and connected without leaks or holes, then no constant water preparation will be required. Of course, some parts will be contained in the water mass, but once they are poured into the heating system, they will react once or more, they will have nowhere to come from.

Induction ones seem to have a low operating cost due to the very rare replacement of components. In reality, this is in high-quality PETN samples; parts change very infrequently, as we discussed above.

But if you need to replace something in the induction room, then you will think twice before doing it. Everything there is sealed in a sealed flask and you can’t get into the middle without physically cutting it.

Another argument for comparison is that an induction boiler does not lose its initial power during its service life. But with a tubular heater, due to scale formation, this happens normally.

Sometimes calculations are even made, according to which, over the course of just one year, the power of the heating element will decrease by 15-20%. And this means its efficiency decreases.

Let's look at this in detail.

In fact, any electric boiler has an efficiency exceeding 98%. And even boilers that operate at very high frequency currents from 25 kHz and above, what can they change for you? Add an extra one and a half percent, but at the same time jump the price by 100%?!

As for deposits on the Tubular Heater element, they are actually present.

In water supply systems in direct-heating storage water heaters, a certain “scale” is deposited on the working component. It actually gradually prevents the water from warming up quickly.

What happens where there is no constant supply of impurities? A small layer of deposits may accumulate on the Tubular Heater, however:

- this layer is not thick enough

- it does not interfere with heat transfer in any way

In other words, practically, both on a clean heating element and on a dirty one, the same amount of energy is transferred, only at different temperatures.

But the most important point to compare is, of course, the final price of the products and how much it will cost to maintain one or another heating system.

Let's really compare two models of approximately the same power:

- induction 25kW (price

85 thousand rub. at the end of 2021)

- heating element 24 kW (price

46 thousand rub. at the end of 2021)

For the first model, the package includes:

- flow meter

- security group

- power distribution cabinet

- temperature sensor

- shut-off control valves

The weight of a 25 kW specimen is about 80 kg.

What is the difference between a good heating element boiler? First of all, it weighs almost 40 kg less.

Moreover, all the electronic filling is hidden in the middle. This means that there is no need for a bulky power distribution cabinet that takes up additional space.

In addition to the equipment listed above for the induction boiler, which the heating element also initially has, it includes additional working units:

- automatic power selection in a couple of steps of 2 kW

This is convenient because the boiler itself can select the power at which it now needs to operate. Outside, the temperature changes slowly, and with a large number of steps, you can flexibly select sufficient power to avoid frequent switching on and off.

You will see with your own eyes the frequent blinking of the light during such switchings. And in addition, powerful electric starters with their own pops and clicks can truly make you jump in surprise every time.

In heating elements, quiet relays or a miniature starter are installed; you can hear their operation only when you are directly near the unit.

- weather-compensated automation

Specifically, she is engaged in switching steps. As soon as the boiler “sees” that the heating rate is too fast, it removes one stage, then another, etc. If the temperature is less than the set one, he adds this step.

In this case, not all 24 kW are switched on at once, but a gradual, smooth increase in power from a very small value. You won’t notice this with your eyes, just by the blinking of the light bulbs.

- thermal protection against overheating and freezing

- low water pressure meter

If your system is leaky and there is a leak somewhere, the boiler simply won’t turn on. In induction, the heating of the core will not stop.

- error indication

You can always go to the boiler and too quickly determine by the error code the breakdown as a result of which it “stood up”.

- expansion tank

- devices for determining pressure, mechanical or electronic

- possibility of connecting an electric storage water heater

Moreover, this feature is already automated. All you have to do is set the water temperature, and the boiler will do everything else itself.

Working at 40 degrees and switching to a storage electric water heater, it will accelerate to 80C on its own, heat up the titanium and then return to its previous mode.

If similar automation was included in electromechanical boilers, then at P = 25 kW they would cost not 85 thousand, but a hundred thousand more. Because in the original version, all control in them is performed based on the flow temperature.

The question of whether or not to purchase an induction boiler, or to choose in favor of a heating element, is naturally decided by everyone for themselves. However, many are increasingly convinced that an induction boiler is not the kind of heating device that should be installed in individual private houses and cottages.

Naturally, not all structures, production and work areas cannot do without induction heating. For example, heating the environment in chemical production, which must remain sterile.

Because of this, it is better to leave this type of heating there rather than dragging it into your home. There is no need to suffer with a complex, heavy, large unit if you can get by with other very graceful solutions.

How they work

In conventional electrical units, energy is transmitted through a tubular electric heater (TEH). This requires the creation of a special area where the liquid will be heated by direct contact with the coolant. The operating principle of the boilers in question is based on electromagnetic induction. Inverter heating works by heating the internal circuit with high frequency currents. The unit includes a heat exchanger. This is where the media is heated to the required level.

The induction boiler can be controlled remotely via a remote control. The liquid in the apparatus is heated using a ferromagnet placed directly into the coolant. The resulting magnetic field generates a current.

Such boilers can also be considered as induction furnaces. The coolant warms up quickly, there are no special requirements for the liquid itself - its quality can be arbitrary.