Main characteristics

| Geography of delivery | any region of the Russian Federation and the CIS |

| Guarantee | 24 months |

| Short description | Modern hot water boiler houses are highly efficient heating systems that can be used to heat rooms of different sizes and types. With us you can choose a boiler room of suitable power quickly and easily |

Questionnaire for ordering a boiler room Implemented objects Calculate the cost of the boiler room

Cost calculation in 1 click!

Studying technology

Just by the name, it’s easy to guess that industrial boiler houses are designed to generate large amounts of heat. Its volume depends on the scale of the enterprise where they are operated. There is a peculiarity in their construction. It lies in the fact that turnkey industrial boiler houses in the city of Moscow and throughout the Russian Federation can only be ordered by legal entities. Their functioning is connected with the heating main. That is why industrial boiler rooms require a special design before installation. Its development is the work of professionals. OJSC "MPNU Energotekhmontazh" has personnel ready to provide such services, regardless of their complexity.

Industrial boiler systems have different designs. There are:

- built into the building;

- free-standing;

- in the form of extensions;

- roof

Industrial gas boiler houses, which are characterized by a high efficiency, are in great demand. At the same time, installations that burn wood, coal and other types of solid fuel continue to be in demand. They are suitable for heating small spaces. They can be installed in certain areas of plants to optimize the cost of heat generation for plants.

Free-standing industrial boiler rooms can be stationary or made in the form of easily transportable block modules. Both liquid fuel and gas are suitable for their operation.

Attached industrial boiler houses are located in close proximity to the buildings that are heated. Roof type installation is carried out on the roof. Management is carried out from there. Built-in industrial gas boiler rooms or devices operating on other types of fuel are an integral element of the building. Their cost is influenced by factors such as the complexity of the design and installation, and the manufacturer.

Equipment for hot water boiler room

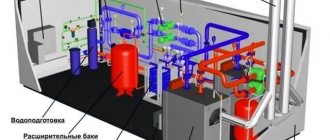

Production (construction) of hot water boiler houses is a process that requires special knowledge and skills. Most often, the following elements are used to equip these systems:

- Control panels.

- Boilers and pumps.

- Heat exchangers.

- Fuel supply systems.

- Heat shields.

- Fans.

- Battery and condensation tanks.

The calculation of the thermal circuit of a hot water boiler house is influenced by many factors. Among them: features of the premises, customer requirements, current safety standards, etc.

The design of a hot water boiler house is calculated taking into account its thermal power, which can vary from 100 kW to 200 MW

In general, it is worth paying attention to the types of installations. Today the following options are available: block water heating boiler house using gas fuel (or any other), stationary and mobile. Therefore, each consumer can choose the best option for him.

It is best to order and buy a hot water boiler room from a specialized company. Competent employees carry out calculations and create projects, specialized specialists are responsible for manufacturing, assembly and commissioning.

Industrial hot water boilers

Industrial hot water boilers are heating equipment designed to heat water, which is subsequently used for heating and/or hot water supply purposes. Industrial hot water boilers are designed, as the name suggests, to prepare hot water to meet the needs of an industrial enterprise. Of course, from the point of view of heat supply, such enterprises include not only facilities that house production facilities, but also any facilities in general intended for human economic activity.

►See Industrial hot water boilers in our catalog

FEATURES OF INDUSTRIAL FACILITIES

So, an industrial facility is not necessarily just a production site or a factory floor. From the point of view of selecting a hot water boiler, such objects can be:

- administrative buildings, for example, plant management;

- warehouses, hangars, garages;

- dining rooms, showers and other premises for household purposes;

- free-standing commercial buildings (shopping centers, business centers, car dealerships, service stations);

- detached buildings for social purposes (hospitals, schools, kindergartens, etc.);

- objects of the hospitality industry - hotels, sanatoriums, recreation centers;

- various production facilities and technological lines

What unites them into the “industrial facilities” group, and what is the difference from residential facilities? After all, the tasks of heating and hot water supply in these areas are not fundamentally different. From a heating engineering point of view, there is no difference. Both residential and non-residential premises will be described by the same construction characteristics: wall thickness, area and type of glazing, thermal insulation properties, etc.

However, industrial facilities differ in terms of approaches to the selection of water heating equipment:

- firstly, they have quite large volumes, which means they require more thermal energy;

- secondly, as a rule, for such objects it is possible to build a clear schedule for hot water consumption, which is determined, as a rule, by technological factors (or behavioral - for hotels, sanatoriums, hospitals, etc.)

LET'S CONSIDER WHAT THESE FEATURES MEAN IN PRACTICE

Large volumes of consumption require the presence of an energy service or position. In some cases, these functions are performed by a third-party contractor, but in industrial enterprises, as a rule, there is a position of power engineer, chief engineer, who are responsible for tasks related to the energy supply of the facility.

The presence of such a service, on the one hand, makes it easier to solve problems of heating and hot water supply - after all, there is a responsible person. On the other hand, his area of responsibility includes not only hot water boilers, but also the entire energy sector as a whole - from lighting to technological equipment. Therefore, the main task of the energy service is the acquisition and installation of equipment that would:

- Effectively

- economical

- would not require constant attention

The second distinctive feature of industrial heat supply is the ability to quite accurately calculate the schedule of thermal energy consumption, especially with regard to the consumption of hot water. Any process of water consumption, in principle, can be formalized and calculated. This opens up opportunities for savings on water heating equipment through the use of storage tanks (we will return to this point).

VARIETIES OF INDUSTRIAL WATER BOILERS

There are many types of hot water boilers, but the most interesting is the division of boilers according to the type of fuel on which they operate. As a rule, it is this criterion that turns out to be the main one in the choice.

GAS INDUSTRIAL WATER BOILERS

Boilers operating on natural gas (less commonly, liquefied gas) are among the most common. In any case, where the consumer has the opportunity to connect to a gas pipe, preference is given to a gas boiler. It is generally accepted that gas is the most economical type of fuel available. Indeed, modern gas water heating boilers are technologically equipped enough to ensure automatic operation, have high efficiency, and are at an acceptable level of safety and environmental friendliness. However, gas boiler equipment also has many disadvantages:

- safety. No matter how high-tech the boiler is, its installation means both the supply of gas and the presence of a burner, that is, an open flame, which means that the risks of fire or explosion are in any case increased;

- installation of the boiler requires approval from the gas supplier. In this case, approval is only possible if a project is provided by a specialized organization - all this entails additional costs of both money and time;

- availability of a valid contract for servicing a gas boiler with a service company;

- higher investments in the purchase and installation of equipment: installation of a chimney, allocation of a separate room for a boiler or construction of a boiler house building.

And it is important not to make a mistake with the equipment - so that it is adapted to our reality in the form of unstable pressure in the gas transportation system.

SOLID FUEL INDUSTRIAL WATER BOILERS

Solid fuel boilers are boilers that burn coal, wood, pellets and other solid fuels. Even modern solid fuel boilers cannot provide a satisfactory level of autonomy, so they are used, as a rule, either for heating/hot water supply of objects in which it is not possible to use other types of fuel, or for those objects in which regular maintenance of the boiler and maintaining it in working condition is possible. The main advantage of such a boiler is the simplicity and low cost of the design - there is little that can break in principle, and also, as a rule, the low cost of fuel. Of course, there are a lot of disadvantages, here are the main ones:

- the need for additional arrangement of a warehouse for a certain supply of fuel;

- need for constant maintenance;

- low level of automation;

LIQUID FUEL INDUSTRIAL WATER BOILERS

Liquid fuel boilers operate on diesel fuel, fuel oil, and kerosene. Taking into account the constantly rising price of fuel, which is a product of oil refining, this type of boiler is rarely used in its pure form. As a rule, such boilers are installed either as a reserve, or have design features that allow you to combine different types of fuel. Such equipment also has disadvantages:

- the need to equip a tank for storing liquid fuel; when using fuel from heavy fractions, it will be necessary to provide a heating system to maintain the fluidity of the fuel;

- the need to arrange a separate room (building) with a chimney;

- high and constantly rising fuel costs;

- the need for regular boiler maintenance.

ELECTRIC INDUSTRIAL WATER BOILERS

Water heating boilers powered by electricity have become widespread throughout the world relatively recently. Despite the high cost of electricity, the demand for electric boilers is steadily growing from year to year. The main advantages of electric industrial hot water boilers:

- autonomy and fully automatic control of the boiler operation;

- relatively low cost of equipment and capital costs. No chimneys or separate rooms are required (unless, of course, we are talking about megawatt installations);

- ease of operation;

- high efficiency at 98-99%;

- absolute environmental friendliness

In general, an electric boiler is a very convenient, least troublesome and effective solution to the problem of heating and hot water supply. Of course, you have to pay extra for these benefits. In the form of payment for kilowatt-hours of electricity.

In defense of electricity as a type of fuel, it must be said that, unlike other types of energy carriers, it is distributed almost everywhere in our country. And if allocated capacities and limits allow, then electric heating can turn out to be a very attractive and even profitable solution in industry.

►See Industrial hot water boilers in our catalog

STORAGE INDUSTRIAL WATER BOILERS

The use of storage tanks (accumulation tanks) allows you to store hot water in advance, say, during the period of reduced consumption or at night. If electric boilers are used to heat water, then when using a two-rate or differentiated tariff for electricity, this allows the enterprise to significantly save money.

When using a separate storage tank, water will circulate along the internal circuit of the hot water boiler, gradually heat up and accumulate in a special heat-insulated container(s). Of course, such a container will have heat losses, but they will be insignificant compared to the savings on tariffs and the cost of heating equipment.

The use of a storage tank allows not only to provide the required volume of hot water during disassembly, but also to use a boiler of lower power. In this case, heating the water will take longer, but in the absence of analysis this is not important. But the savings on equipment costs can be manifold.

Therefore, industrial storage water heaters are becoming increasingly widespread. Most of the types on the market already include one or several standard storage tanks. However, some models can connect directly to a customer's already installed tank.

INDUSTRIAL WATER BOILERS TERMANIK

Among all types of electric industrial boilers, induction heaters stand out. On the pages of our website we have already studied in detail the differences, advantages and disadvantages of different types of electric heaters.

In short, an induction heater is a device that allows you to convert alternating current with an industrial frequency of 50 Hz into an electromagnetic field, which in turn heats up the heat exchange device through which the coolant (water) circulates.

The operating principle of an induction hot water boiler is demonstrated very clearly in the following video:

INDUCTION WATER BOILERS HAVE THE FOLLOWING DISTINCTIVE PROPERTIES:

- very high durability, reaching 30 years

- reliability due to the absence of loaded, high-temperature and mechanically wearing elements;

- ease of use;

- efficiency and economy; The efficiency of the installations is 98%, the power factor is 0.98.

Induction water heating boilers are used both for autonomous heat supply and hot water supply of any objects. But it should be noted that the manufacturer of TERMANIK brand heaters specializes in creating boilers intended primarily for the industrial market, and its model range is aimed specifically at this segment of consumers.

TERMANIK brand equipment intended for hot water supply tasks is supplied with storage tanks and are fully equipped and ready-to-connect hot water supply installations. However, there are also modifications designed for flow-through heating, as well as separate heating units connected to the customer’s tank.

►See Industrial hot water boilers in our catalog

INDUSTRIAL WATER BOILERS: SELECTION FEATURES

Selecting boiler equipment is not an easy task, requiring consideration of many factors, such as the construction characteristics of the facility, consumption schedule, tariff system, electricity limits, etc. To obtain a balanced solution, we advise you to seek help from the specialists of Scientific and Production Enterprise “Thermal Technologies”, who have the necessary experience and knowledge to find optimal solutions for heat supply to industrial facilities.

If you are ready to formulate the tasks that your company is currently facing, send a description. You can also use standard TOR forms on our website, in the “Contacts” section. Calculations on the composition, characteristics, quantity and power of industrial hot water boilers produced by NPP "Thermal Technologies" are made for customers free of charge.

commissioning of hot water boiler house

The commissioning procedure for a hot water boiler house includes several stages. The following is carried out on the territory of the plant:

- Checking boilers and monitoring their operation.

- Adjusting safety valves.

- Setting up automation and checking security systems.

- Checking the joint operation of equipment.

- Troubleshooting detected problems.

Maintenance of hot water boiler houses is carried out by specialists who have been certified and have permission to carry out such work.

How to choose the right series

When choosing a hot water boiler, pay attention to the main points, among which the type of fuel used is considered predominant. Technical diagnostics and intended tasks are taken into account: solid fuel or gas modifications of type 3 KD are considered suitable for a private home.

Industrial units using diesel fuel are similar in parameters to their gas counterparts. They can operate on 2 types of fuel, which makes it easier to operate and draw up a process protection plan. Coal and wood-burning versions are aimed at producing hot water for heating systems.

What is the difference between fire tube and water tube structures?

Water heating boilers that can be found on the market these days do not differ much in design. More significant differences lie in the maximum power of the devices and specific manufacturers.

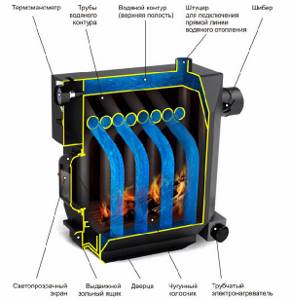

If we consider the design features, then boilers can be divided into gas-tube (another name for fire-tube) and water-tube:

- Fire tube models. The main distinguishing feature is the presence of special tubes through which heated combustion products of energy carriers move. If we consider the principle of operation of this equipment, then its basis can be considered the use of automated burners, which are equipped with blower fans. The water is heated using smoke tubes located outside. It is necessary to take into account that, as household ones, such models are almost never used.

- Water tube models. Their design feature is special boiling tubes, with the help of which the coolant moves. And these tubes are heated by fuel combustion products. Boilers of this type warm up quite quickly, and if the load changes, they are quite easy to adjust. In addition, such equipment is quite resistant to serious overloads. If we consider it from the point of view of explosion hazard, then its probability is quite low.

All hot water heating equipment is also divided according to its temperature level. For low-temperature models, the maximum permissible maximum temperature is 115 degrees, and for overheating hot water boilers this temperature is 150 degrees or more.

It should be noted that the low-temperature operating mode uses fuel quite economically, but at the same time the surface of the unit is covered with condensate, which does not have the best effect on materials that are in direct contact with the products of combustion of energy resources. Because of this, quite high demands are placed on the materials used in the production of boilers.

Devices that generate superheated water can be characterized by a fairly long service life and a high degree of reliability. The operating process of such units is almost silent, and waste emissions are minimal. This equipment is also equipped with simple and convenient control systems. Installation is quite quick and does not require complex maintenance.

Most fire- and water-tube units are double-circuit, but there are also many single-circuit water heating boilers. If the device is equipped with two circuits, then the heated liquid will be used not only for heating the room, but for domestic needs (plumbing).

It is also worth noting that the design of these units involves special circulators, the task of which is to intensify water circulation; membrane-type expansion tanks can also be included in the design.

Internal technological circuits

- Heating of the boiler room is an adjustable circuit for radiators.

- Ventilation of the boiler room is an independent circuit through a plate heat exchanger with heating of the non-freezing coolant.

- Combustion air heating is an independent circuit through a plate heat exchanger with heated non-freezing coolant.

The scheme also provides for a cold water input, a booster pumping station, a water treatment unit and a make-up water storage tank.

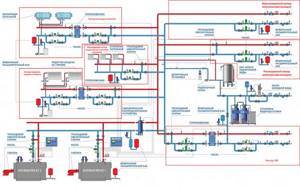

Boiler and hydraulic distribution device

A boiler unit is a fully factory-ready product that includes a boiler, burner, circulation pump, control and shut-off valves, safety valves, thermometers, pressure gauges, temperature and pressure sensors connected to the automation system.

The boiler unit automation collects data from temperature sensors on the boiler supply pipe, as well as from a strategy sensor installed in the hydraulic pointer, and regulates the boiler power with the burner. Sensors are installed on the supply pipeline that limit the maximum temperature of the coolant at the outlet of the boiler. Based on the temperature sensor at the entrance to the boiler, the automation organizes protection of the boiler from cold coolant.

A three-way mixing valve on the return pipeline mixes coolant from the supply pipeline, increasing the temperature at the inlet to the boiler until it reaches the minimum required value. This prevents condensation from the flue gases, which leads to corrosion of the boiler. The advantage of a three-way mixing valve is its ability, if necessary, to completely shut off the flow of cold coolant, closing the boiler to internal circulation until it is heated to the minimum required temperature. This operation of the three-way mixing valve implies variable flow in the boiler circuit. To stabilize it, it is necessary to provide a hydraulic arrow that separates the hydraulics of the boiler circuit and the consumer circuit (or the heating circuit of the heat exchangers), stabilizing a possible imbalance of costs.

Minimum and maximum pressure sensors are installed on the boiler supply pipe, turning off the burner when the pressure decreases or increases. A decrease in pressure can cause boiling of the coolant; an increase can cause a violation of the integrity of the boiler. As additional protection against overpressure, safety valves are installed on the boiler that release coolant from the boiler, thereby reducing the pressure in it.

The circulation pump of the boiler unit works continuously when the burner is operating. When the burner and the entire boiler unit are switched off, the pump also switches off after a certain time and the three-way mixing valve switches to the internal circulation position. This ensures that there is no coolant circulation through the idle boiler.

To compensate for thermal expansion of the coolant, a membrane expansion tank is connected to the boiler drain pipe. As the temperature of the coolant increases and, as a consequence, its volume increases, the expansion tank accumulates excess coolant. When the temperature drops, the reverse process of coolant transfer from the tank to the boiler occurs, preventing vacuum in it.

The choice of the boiler drain pipe is determined by the fact that this is the point with the lowest temperature. An expansion tank with an intermediate cooling tank and a safety valve is installed on a common manifold from the boiler units. The expansion tank accumulates thermal expansion of the boiler circuit coolant. It is connected to the return manifold through an intermediate cooling tank, where the coolant is additionally cooled, which extends the service life of the expansion tank. To protect the expansion tank from overpressure, a safety valve is additionally installed.

The boiler units operate in a cascade. One of the boilers is assigned as the master (MASTER), the other as the slave (SLAVE). The lead boiler is always in operation. When it reaches maximum power and a request to increase power comes, the slave boiler is switched on.

The hydraulic distribution device is a cylindrical vessel with four connections:

- hot coolant inlet from boilers,

- outlet of cold coolant to boilers,

- outlet of hot coolant to consumers,

- cold coolant inlet from consumers.

At the outlet of the hot coolant, a strategy sensor is installed on consumers, through which the power of the boilers and the number of operating boilers are controlled. An air vent is installed in the upper part of the hydraulic needle, and a drain valve is installed in the lower part. For optimal operation of the hydraulic needle, it is necessary that the coolant flow from the boilers exceeds the coolant flow from consumers by at least 35%. The difference in flow rates flows along the body of the hydraulic needle from the inlet to the outlet on the side of the boilers.