Air exchange rate in retail premises (shops)

| № | Room | Estimated air temperature for the cold period of the year, °C | Air exchange rate or the amount of air removed from the premises | |

| influx | hood | |||

| 1 | Sales areas of stores with an area of 400 m2 or less: | |||

| food | 16 | — | 1 | |

| non-food | 16 | — | 1 | |

| 2 | Sales areas of stores with an area of more than 400 m2: | |||

| food | 16 | By calculation | By calculation | |

| non-food | 16 | By calculation | By calculation | |

| 3 | Razrubochnaya | 10 | 3 | 4 |

| 4 | Unloading premises | 10 | By calculation | By calculation |

| 5 | Premises for preparing goods for sale (if placed in a separate room), picking, receiving | 16 | 2 | 1 |

| 6 | Storerooms (unrefrigerated): | |||

| bread, confectionery; | 16 | — | 0,5 | |

| gastronomy, fish, milk, fruits, vegetables, pickles, wine, beer, drinks; | 8 | — | 1 | |

| shoes, perfumes, household chemicals, chemicals; | 16 | — | 2 | |

| other goods | 16 | — | 0,5 | |

| 6.1 | Room for preparing goods for sale (if placed in a separate room), picking, acceptance, expeditions | 16 | 2 | 1 |

| 7 | Premises for displaying new products (if placed in a separate room) | 16 | 2 | 2 |

| 8 | Ironing | 16 | By calculation | By calculation |

| 9 | Garbage chambers (unheated) | — | — | — |

| 10 | Room for mechanized pressing of paper waste | 16 | — | 1,5 |

| Storage facilities: | ||||

| 11 | packaging materials and equipment | 16(8) | — | 1 |

| 12 | exchange fund containers | — | — | 1 |

| 13 | containers | 8 | — | 1 |

| 14 | cleaning equipment, detergents | 16 | — | 1,5 |

| 15 | Linen room | 18 | — | 0,5 |

| 16 | Workshops, laboratories | 18 | 2 | 3(2) |

| 17 | Refrigerated containment chambers: | |||

| meat, semi-finished products, gastronomy | 0 | — | — | |

| fish | -2 | — | — | |

| vegetables, fruits, confectionery, drinks | 4 | 4 | 4 | |

| ice cream, dumplings, etc. | -12 | Periodically | ||

| food waste | 2 | — | 10 | |

| 18 | Air cooled machine rooms | 5 | By calculation | |

| 19 | Water-cooled refrigerated machine rooms | 5 | 2 | 3 |

| 20 | Office premises, staff room, main cash register, security room, automated control center | 18 | — | 1 |

| 21 | Dressing rooms, utility room for catering establishment staff, meal room | 16 | — | 1 |

| 22 | Public toilets for customers and staff toilets | 16 | — | 50 m3/h per toilet |

| 23 | Showers | 25 | — | 5 |

| 24 | Dispensary room (if the store is located in the underground floors) | 20 | — | 60 m3/h per person |

| 25 | Premises for receiving and issuing orders | 12 | — | 1 |

| 26 | Glass container reception premises | 16 | — | 1 |

| 27 | Health center | 20 | 1 | 1 |

Cleaning ventilation in a restaurant

Maintenance of ventilation and disinfection of air conditioner air filters are mandatory and must be carried out regularly. Cleaning ventilation in a restaurant involves not only servicing the air ducts that directly exhaust and supply air inside the dining room, bar, lounge, etc. They need to be cleaned of dust, and the fan mechanism must be inspected, which must work properly in order to remove specific food odors (for example, a cheese factory restaurant).

In addition, it is necessary to constantly clean the ventilation from grease in a restaurant (Mytishchi), in particular the kitchen. Along with the removed hot flow, fat particles get there and settle on the inner surface of the air ducts and fan blades, thereby complicating their functioning. Therefore, it is important to carry out timely maintenance of the ventilation system of the hot shop of a restaurant kitchen.

Air exchange rate in the premises of public catering establishments

| № | Names of premises | Design air temperature, °C | Air change rate per hour | |

| influx | hood | |||

| 1 | Hall, distribution room | 16 | According to calculations, but not less than 30 m3/h per person. | |

| 2 | Lobby, antechamber | 16 | 2 | — |

| 3 | Cookery store | 16 | 3 | 2 |

| 4 | Hot shop, confectionery baking room | 5 | According to calculations, but not less than 100 m3/h per person. | |

| 5 | Shops: pre-cooking, cold, meat, poultry, fish, herbs and vegetables processing | 18 | 3 | 4 |

| 6 | Production Manager's Office | 18 | 2 | — |

| 7 | Room for flour products and finishing of confectionery products, linen | 18 | 1 | 2 |

| 8 | Room for cutting bread, for preparing ice cream, serving room, utility room | 18 | 1 | 1 |

| 9 | Washing: tableware, kitchen utensils, vessels, containers | 18 | 4 | 6 |

| 10 | Director's office, office, main cash register, rooms for waiters, staff, storekeeper | 18 | 4 | 6 |

| 11 | Dry food pantry, equipment pantry, wine and vodka pantry, beer storage room | 12 | — | 1 |

| 12 | Pantries of vegetables, pickles, containers | 5 | — | 2 |

| 13 | Reception | 16 | 3 | — |

| 14 | Engine room of refrigerated chambers with air-cooled units | By calculation | By calculation | By calculation |

| 15 | The same, with water-cooled units | — | 3 | 4 |

| 16 | Repair shops | 16 | 2 | 3 |

| 17 | Premises of public organizations | 16 | 1 | 1 |

| 18 | Refrigerated storage chambers: | |||

| meat | 0 | — | — | |

| fish | -2 | — | — | |

| dairy and fat products, gastronomy | 2 | — | — | |

| semi-finished products, including highly prepared | 0 | — | — | |

| vegetables, fruits, berries, drinks | 4 | 4 | 4 | |

| confectionery | 4 | — | — | |

| wines and drinks | 6 | — | — | |

| ice cream and frozen fruit | -15 | — | — | |

| food waste | 5 | — | 10 | |

| 19 | Smoking room | 16 | — | 10 |

| 20 | Unloading premises | 10 | By calculation | By calculation |

Notes: 1. The air temperatures in the rooms (except for refrigerated chambers) indicated in the table are calculated when designing heating systems.

2. In buffets, bars, cocktail lounges, banquet halls located in separate rooms, the air ratio is minus 3.

3. The air temperatures in the refrigerated chambers indicated in the table are maintained around the clock throughout the year. In chambers for the simultaneous storage of meat and fish or meat and fish semi-finished products, accept temperatures of ±0 ° C; for semi-finished vegetable products +2 °C; for storing all products (1 chamber in the enterprise) ±2 °C.

Ventilation in the kitchen of catering establishments

This part of restaurants, canteens and cafes should be given special attention for several reasons:

- concentration of more heat sources here;

- formation of odors and combustion products during cooking.

It was mentioned above that in most rooms, when planning ventilation, a supply and exhaust system is implied. In this case, in the kitchen (to be more precise, in the hot shop) the use of another type of device is required - special umbrellas. They provide only targeted air removal and are placed directly above the places where foreign odors and heat are generated.

Depending on their location, these types of exhaust hoods come in two types: wall-mounted and island-mounted. When installing them, a separate air duct is required; they cannot be connected to a common supply and exhaust system. Also, when choosing a device model, it is important to correctly determine its dimensions and air vent cross-section.

The material used to make exhaust hoods is stainless steel or galvanized steel. Additionally, they must be equipped with grease traps, allowing them to effectively remove oil particles along with air. When installing an umbrella over a grill, to ensure fire safety, you must check whether it contains a spark arrestor.

Air flow rates for modulated equipment

| № | Equipment | Brand | kW | Air quantity, m3/h | |

| Exhaust | Supply air | ||||

| 1 | Electric stove | PE-0.17 | 4 | 250 | 200 |

| 2 | PE-0.17-01 | 4 | 250 | 200 | |

| 3 | Electric stove | PE-0.51 | 12 | 750 | 400 |

| 4 | PE-0.51-01 | 12 | 750 | 400 | |

| 5 | Frying cabinet | ShZhE-0.51 | 8 | 400 | — |

| 6 | ShZhE-0.51-01 | 8 | 400 | — | |

| 7 | ShZhE-0.85 | 12 | 500 | — | |

| 8 | ShZhE-0.85-1 | 12 | 500 | — | |

| 9 | Electric device, cooking | UEV-60 | 9,45 | 650 | 400 |

| 10 | Mobile boiler | KP-60 | — | — | — |

| 11 | deep fryer | FE-20 | 7,5 | 350 | 200 |

| 12 | Cooking kettle with capacity, l: | ||||

| 100 | KE-100 | 18,9 | 550 | 400 | |

| 160 | KE-160 | 24 | 650 | 400 | |

| 250 | KE-250 | 30 | 750 | 400 | |

| 13 | Steamer | APE-0.23A | 7,5 | 650 | 400 |

| APE-0.23A-01 | 7,5 | 650 | 400 | ||

| 14 | Electric frying pan | SE-0.22 | 5 | 450 | 400 |

| SE-0.22-01 | 5 | 450 | 400 | ||

| SE-0.45 | 11,5 | 700 | 400 | ||

| SE-0.45-01 | 11,5 | 700 | 400 | ||

| 15 | Steam table | ITU-0.84 | 2,5 | 300 | 200 |

| ITU-0.84-01 | 2,5 | 300 | 200 | ||

| 16 | Mobile food warmer | MP-28 | 0,63 | — | — |

Source: “Design of public catering establishments” Reference manual for SNiP 2.08.02-89

What to consider when designing

The preliminary stage is the most important. Design is carried out in accordance with the size and features of the premises. Split systems and supply ventilation are recommended. Industrial ventilation with the right approach is cheaper not only during installation, but also during operation.

A number of requirements are taken into account during design and installation:

- installation of suitable air filters;

- equipment of devices that collect soot and fat deposits;

- When installing air ducts, a slope towards the sink is required.

When selecting the optimal system, preliminary consultation with specialists is recommended. This allows you to choose the best equipment that is suitable taking into account the size, operating characteristics and shape of the premises.

Air exchange rate in the premises of sports and recreational institutions

| № | Names of premises | Design air temperature, °C | Air change rate per hour | |

| influx | hood | |||

| 1 | Gymnasiums without seats for spectators (except for rhythmic gymnastics halls) | 15 | According to calculations, but not less than 80 m3/h per student | |

| 2 | Rhythmic gymnastics halls and choreographic classes | 18 | According to calculations, but not less than 80 m3/h per student | |

| 3 | Rooms for individual strength and acrobatic training, individual warm-up before competitions | 16 | 2 | 3 |

| 4 | Workshops | 16 | 2 | 3 |

| 5 | Classrooms, teaching rooms, rooms for instructors and coaching staff, judges, press, administrative and engineering staff | 18 | 3 | 2 |

| 6 | Household premises for workers and public order officers | 18 | 2 | 3 |

| 7 | Fire station room | 18 | — | 2 |

| 8 | Wardrobe for outerwear for exercising | 16 | — | 2 |

| 9 | Locker room (including for massages) | 25 | Balanced including showers | 2 (via showers) |

| 10 | Showers | 25 | 5 | 10 |

| 11 | Massage | 22 | 4 | 4 |

| 12 | Sanitary facilities: | |||

| common use | 16 | — | 100 m3/h per toilet or urinal | |

| for those working out (at the changing rooms) | 20 | — | 50 m3/h per toilet or urinal | |

| personal use | 16 | — | 25 m3/h per toilet or urinal | |

| 13 | Washrooms in public sanitary facilities | 16 | — | Due to sanitary facilities |

| 14 | Inventory in the halls | 15 | — | 1 |

| 15 | Storerooms and warehouses: | — | ||

| with permanent presence of service personnel; | 16 | — | 2 | |

| with short-term stay of service personnel | 10 | — | 1 | |

| 16 | Warehouses for reagents, household chemicals and paints | 10 | — | 2 |

| 17 | Rooms for drying sportswear | 22 | 2 | 2 |

Determining the required flow

Ventilation in the dining room

For dining rooms, two zones are distinguished - for smoking guests and non-smoking guests; ventilation calculations for each zone are different. Air flow is determined based on the removal of excess heat from each visitor (according to the norm of 100 kcal/h per guest [TSN 31-320-2000]) or from the minimum required air flow:

- for smokers – 100 m3/h*person [STO NP ABOK 2.1-2008]

- for non-smokers 30 m3/h*person

Ventilation of hot shop (kitchen)

There are no standard standards for calculating workshop ventilation. The consumption is calculated for each specific case separately, based on the condition of removing the heat generated from kitchen equipment (stoves, stoves, heating cabinets, etc.), and at least 100 m3/h per person is assumed. The calculation methodology is quite complex, so we will not present it in this article; we will provide data for two specific cases from our example (the methodology can be found in the manual NP ABOK 7.3.-2007).

— hood for umbrella 1000x600 – 900 m3/h

— hood for an umbrella 2000x800 – 2500 m3/h (it is recommended to connect two air ducts to the umbrella to reduce air speed)

Ventilation of sanitary units

Air flow is determined based on the number of appliances in the bathrooms:

— toilet – 50 m3/h

— urinal – 25 m3/h

This is interesting: Ventilation in a hookah bar

Air exchange rate in the premises of a financial institution

| № | Names of premises | Design air temperature, °C | Air change rate per hour | |

| influx | hood | |||

| 1. | Operating and cash rooms | 18 | Based on the assimilation of excess heat and moisture, but not less than twofold air exchange | |

| 2. | Common work rooms, coin counting desks | 18 | 2 | 2 |

| 3. | Room for meetings and negotiations | 18 | 3 | 3 |

| 4. | Banknote counter | 18 | 3 | 3 |

| 5. | Computer equipment premises, computer center | 18 | Based on the assimilation of heat and moisture excess | |

| 6. | Communications (teletypewriter) and photocopying room | 18 | 2,5 | 2,5 |

| 7. | Offices and reception areas | 18 | 1,5 | 1,5 |

| 8. | Archive, storage room for forms, storage room for equipment and inventory, storage room for banking materials, room for storing personal belongings of cashiers | 18 | — | 1,5 |

| 9. | Repair shops | 18 | 2 | 2 |

| 10. | Meal room, buffet | 16 | 3 | 4 |

| 11. | Room for storing weapons, loading and cleaning weapons | 16 | — | 1 |

| 12. | Boxes for cash-in-transit vehicles | 18 | According to the design standards for parking garages | |

| 13. | Security premises with fire station | 18 | 1 | 1,5 |

| 14. | Women's personal hygiene rooms | 23 | — | 5 |

| 15. | Sanitary facilities | 16 | — | 50 m3/h per toilet or urinal |

| 16. | Lobby | 16 | 2 | — |

| 17. | Dressing rooms | 16 | — | 2 |

| 18. | Premises for placing sources of uninterruptible power supply | 16 | Based on the assimilation of heat and moisture excess | |

Ventilation equipment

Most often, a standard set of equipment is used

- Supply duct fan is used most often not only because it is cheaper than its analogues (radial, rectangular, etc.), but also because it is easier to install and convenient to place (compact, installed directly on the air duct). Also, these fans have low electrical power consumption and do not require maintenance.

- The exhaust fan is a duct type, similar (or exactly the same) to the supply fan.

- Filter – a coarse filter is used. Placed on the supply system to clean the air from dust and coarse particles. Filter

- Heater (electric/water). An electric heater is cheaper and easier to install, but more expensive to operate, since even a small flow rate of 1000 m3/h requires, according to calculations in accordance with SP 60.13330.2012, at least 15 kW of electrical power. The cost of operating an electric heater during the heating period (214 days for Moscow) will average 45 thousand rubles. A water heater is much more expensive at the procurement stage, since it requires an automatic control system (maintains a constant temperature of the supply air and protects the heater from defrosting), but at the same time it is noticeably cheaper to operate, since heating is carried out by circulating water from the central heating system. Heater (heater)

Air exchange rate in administrative and domestic buildings

SNiP 2.09.04—87*

| № | Premises | Temperature during the cold season | Frequency or volume of air exchange, m3/h | |

| Inflow | Hood | |||

| 1. | Lobbies | +16° | 2 | — |

| 2. | Heated passages | Not lower than 6°C of the design temperature of the rooms connected by heated passages | — | — |

| 3. | Streetwear wardrobes | +16° | — | 1 |

| 4. | Dressing rooms for joint storage of all types of clothing with incomplete dressing of workers | +18° | Based on compensation for exhaust from showers (but not less than one air exchange per hour) | According to clause 4.8 |

| 5. | Dressing rooms for showers (pre-showers), as well as with a complete change of clothes for workers a) dressing rooms for work clothes | +23° | 5 | 5 |

| b) dressing rooms for home (street and home) clothes | +23° | Based on compensation for exhaust from showers (but not less than one air exchange per hour) | According to clause 4.8 | |

| 6. | Showers | +25° | — | 75 m3/h for 1 shower screen |

| 7. | Restrooms | +16° | — | 50 m3/h for 1 toilet and 25 m3/h for 1 urinal |

| 8. | Washrooms at restrooms | +16° | — | 1 |

| 9. | Smoking rooms | +16° | — | 10 |

| 10. | Rooms for rest, heating or cooling | +22° | 2 (but not less than 30 m3/h per 1 person. | 3 |

| 11. | Premises for women's personal hygiene | +23° | 2 | 2 |

| 12. | Rooms for repair of workwear | +16° | 2 | 3 |

| 13. | Shoe repair facilities | +16° | 2 | 3 |

| 14. | Premises of departments, design bureaus, public organizations, area: a) no more than 36 m2 | +18° | 1,5 | — |

| b) more than 36 m2 | +18° | By calculation | ||

| 15. | Rooms for drying work clothes | According to technological requirements within 16-33°C | Same | |

| 16. | Rooms for dust removal of work clothes | +16° | « | |

Source: Administrative and domestic buildings SNiP 2.09.04—87*

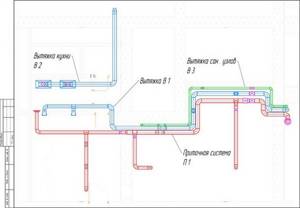

Typical cafe ventilation scheme

All public catering establishments must have a supply and exhaust ventilation system with a balance of supply and exhaust air flow (pressure imbalance must be avoided). Supply ventilation serves to supply fresh air to the premises. Exhaust - to remove polluted air. An air conditioning system is a system that allows you to maintain a given temperature in a room.

Below we will consider in detail an example of ventilation for a cafe with an area of 120 m2. The ventilation of this cafe consists of the following systems:

1. Supply ventilation (system P1) – provides fresh air to the dining room and kitchen. For rooms with less than 50 seats, it is allowed to combine supply ventilation into a single system for the dining room and kitchen.

2. Exhaust ventilation (system B1) – this system is a general mechanical ventilation. Its function is to remove polluted air from the working area of the dining room.

3. Exhaust ventilation (system B2) – kitchen hood. Removes hot air contaminated with fats and odors. Air collection is carried out by kitchen metal umbrellas (with grease filters) located directly above the stoves and stoves.

4. Exhaust ventilation (system B3) – bathroom exhaust. nodes In this example, a mechanical hood is provided with a fan located outside. But if next to the san. Since the ventilation riser is located in the unit, it is allowed to make a natural exhaust system.

Exhaust ventilation diagram

This organization of air exchange ensures a comfortable stay for guests in the cafe, since fresh air is supplied to the dining room, and the main exhaust is carried out from the “dirty areas”. Reduced pressure in the kitchen and bathrooms prevents odors from entering “dirty” areas into “clean” ones.

Air exchange rate in healthcare institutions

| № | Name of premises | T, °C | Air exchange rate | Category by frequency of premises | Exhaust ratio with natural air exchange | ||

| influx | hood | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| I. | Hospitals, clinics, emergency and ambulance stations | ||||||

| 1. | Manipulation-toilet rooms for newborns | 25 | 2 | H | 2 | ||

| 2. | Manipulation with the use of chlorpromazine | 22 | 8 | 10 | G | not allowed | |

| 3. | Doctors' offices, staff rooms, rest rooms for patients using hydrotherapy and mud therapy procedures, acupuncture rooms, discharge rooms, audiometry rooms, anthropometry rooms, dispatch rooms for receiving calls and sending teams, room for filling out documents, rest room for dispatchers, doctors, paramedics, orderlies, drivers , mobile teams, medical statistics | 20 | influx from the corridor | 11 | H | 1 | |

| 4. | Angiography rooms, X-ray diagnostic rooms, treatment rooms and dressing rooms, fluorography rooms, electrolight therapy rooms, massage room | 20 | 3 | 4 | G | not allowed | |

| 5. | Undressing rooms in X-ray rooms | 20 | 3 | — | H | » | |

| 6. | Procedural for X-ray. dental images, washing laboratory glassware, pathology departments, control room of X-ray rooms and radiology departments, photo laboratory | 18 | 3 | 4 | G | » | |

| 7. | Sterilization in operating rooms | 18 | — | 3 septic departments | G | 2 | |

| 3 | aseptic departments | H | 2 | ||||

| 8. | Laboratories and rooms for analysis, rooms (rooms) for radiotelemetry, endocrinology and other studies, rooms for receiving, sorting and taking samples for laboratory tests, installation and washing rooms for an artificial kidney and rooms for a heart-lung machine, solution-demineralization, preparation laboratories, rooms for staining smears, weighing, colorimetric, media preparation, material and hardware laboratories, fixation, prescription, rooms for the preparation of dressings and surgical materials and linen, control, acquisition and packaging of instruments, reception, disassembly, washing and drying of surgical instruments, syringes, needles , catheter, treatment rooms for antipsychotic treatment, radio post, voice recording center, current sterilization rooms, hardware room | 18 | — | 3 | see table 3 | 2 | |

| 9. | Halls of therapeutic physical culture | 18 | 50 m3/hour per student in the gym 80% | 100 % | G | ||

| 10. | Functional diagnostic rooms, sigmoidoscopy rooms | 22 | — | 3 | G | 2 | |

| 11. | Rooms for physical therapy, mechanotherapy, dental rooms, probing rooms, rooms for deworming | 20 | 2 | 3 | G | 2 | |

| 12. | Premises (rooms) for sanitary treatment of patients, showers, personal hygiene cabins, premises for subaqueous, hydrogen sulfide and other baths (except radon), premises for heating paraffin and ozokerite, therapeutic swimming pools | 25 | 3 | 5 | G | 2 | |

| 13. | Premises for storing plaster bandages, plaster, museums and preparatory rooms in pathology departments, compressor inhalation rooms, central linen rooms, storerooms for infected linen and bedding, storerooms for household equipment, storerooms for patients' things and ironing, instrumental materials, storerooms for reagents and equipment in pathology departments departments, rooms for routine repairs of physiotherapy equipment, storage of boxes for visiting teams, a current supply of medicines, a pharmacy room, a pantry for a month's supply of medicines, a pantry for non-sterile materials and linen | 18 | — | 1 | G | 1 | |

| 14. | Sterilization-autoclave central sterilization rooms: | 18 | by calculation | is allowed | |||

| a) clean compartment | 100 % | — | H | ||||

| b) dirty compartment | — | 100 % | G | ||||

| 15. | Rooms for washing, sterilization and storage of vessels, pots, washing and drying oilcloths, sorting and temporary storage of dirty linen, storage of cleaning items, rooms for temporary storage of linen and solid waste contaminated with radioactive substances, storage rooms for acids and disinfectants, stretcher washing rooms and oilcloths, a room for drying clothes and shoes of visiting teams | 18 | — | 5 | G | 3 | |

| 16. | Registration offices, information lobbies, dressing rooms, rooms for receiving packages for patients, a waiting room, storerooms for warm clothes on the verandas, pantries, dining rooms for patients, distribution rooms with utility rooms in milk distribution points, storerooms for patients’ clothes and clothes, medical archives | 18 | — | 1 | G | 1 | |

| 17. | Rooms for processing rubber gloves, for washing and sterilizing tableware and kitchen utensils in the buffet and dining rooms, hairdressing salons for serving patients, dummy rooms | 18 | 2 | 3 | G | 2 | |

| 18. | Storage facilities for radioactive substances, packaging and washing in radiological departments, washing in laboratories | 18 | 5 | 6 | G | not allowed | |

| 19. | Treatment rooms in rooms for static and mobile tele-gamma therapy, rooms for centralization in rooms for mobile tele-gamma therapy, treatment rooms for X-ray therapy, microwave therapy rooms, ultra-high frequency therapy rooms, thermotherapy rooms, wrap rooms, rooms for preparing solutions for radon vayans, ultrasound treatment rooms | 20 | 4 | 5 | G | » | |

| 20. | Changing rooms and undressing rooms in hydrotherapy departments | 23 | influx according to the balance of exhaust from the halls with baths, mud procedures | H | 2 | ||

| 21. | Corpse storage rooms | 2 | — | 3 | G | 3 | |

| 22. | Premises for radon baths, mud therapy rooms. shower room with a lectern, mud therapy rooms for gynecological procedures | 25 | 4 | 5 | G | doesn't go down | |

| 23. | Premises for storing and regenerating dirt | 12 | 2 | 10 | G | » | |

| 24. | Rooms for dressing corpses, issuing corpses, storage rooms for funeral supplies, for processing and preparing for burial of infected corpses, rooms for storing bleach | 14 | — | 3 | G | » | |

| 25. | Disinfection chamber premises: | ||||||

| a) reception rooms; | 16 | from a clean compartment | 3 | G | » | ||

| b) dirty compartments: | from a clean compartment | 5 | G | » | |||

| c) unloading (clean) compartments | 5 | Through dirty compartments | |||||

| 26. | Sluices for hydrogen sulfide baths | 25 | 3 | 4 | H | not allowed | |

| 27. | Undressing rooms for hydrogen sulfide baths | 25 | 3 | 3 | H | » | |

| 28. | Room for preparing a solution of hydrogen sulfide baths and storing reagents | 20 | 5 | 6 | G | » | |

| 29. | Room for washing and drying sheets, canvases, tarpaulins, mud kitchens | 16 | 6 | 10 | G | » | |

| 30. | Inhalations (procedural) | 20 | 8 | 10 | G | ||

| 31. | Sectional | 16 | — | 4 | G | 4 | |

| 32. | Airlocks in front of neonatal wards | 22 | by calculation, but not less than 5 times the exchange | H | not allowed | ||

| 33. | Rooms for the discharge of postpartum women and irradiation of children with a quartz lamp | 22 | — | 1 | H | 1 | |

| 34. | Bathrooms | 20 | — | 50 m3 for 1 toilet and 20 m3 for 1 urinal | G | 3 | |

| 35. | Washrooms | 20 | — | 3 | G | 3 | |

| 36. | Enema | 20 | — | 5 | G | 2 | |

| 37. | Airlocks in boxes and semi-boxes of infectious diseases departments | 22 | by calculation, but not less than 5 times the exchange | H | not allowed | ||

| 38. | Small operating rooms | 22 | 10 | 5 | H | 1 | |

| 39. | Premises of hospital pharmacies (see section General self-supporting pharmacies) | ||||||

| Vivariums5) | |||||||

| 40. | Quarantine section for entry of vehicles with animals. Reception room with a warm vestibule | 16 | 1 | 1 | G | 1 | |

| 41. | Sink for dogs, cats, miniature pigs with bathtub and circular shower | 22 | 3 | 5 | G | 2 | |

| 42. | Hot air drying for dogs and miniature pigs | 25 | 3 | 5 | G | 2 | |

| 43. | Room for keeping laboratory animals:6) | ||||||

| a) mice | 20:22 | 10 | 12 | G | 2 | ||

| b) hamsters | 20 | 10 | 12 | G | 2 | ||

| c) guinea pigs | 14:16 | 8 | 10 | G | 2 | ||

| d) rabbits7) | 5 | 8 | 10 | G | 2 | ||

| e) dogs (with access to walking) | 14 | 8 | 10 | G | 2 | ||

| e) cats | 18 | 10 | 12 | G | 2 | ||

| g) sheep (with access to walking) | 5 | 10 | 12 | G | 2 | ||

| h) dwarf pigs | 18 | 10 | 12 | G | 2 | ||

| i) roosters | 18 | 10 | 12 | G | 2 | ||

| 44. | Staff quarters | 18 | 1 | 1 | H | 1 | |

| 45. | Warehouse of cages and equipment | 10 | — | 1 | G | 1 | |

| 46. | Inspection of sick animals and disinfection | 20 | 8 | 10 | G | 2 | |

| 47. | Isolator for large animals | 15 | 8 | 10 | G | 2 | |

| 48. | Premises for storing and preparing disinfectants (with a fume hood) | 18 | according to technologists | G | 3 | ||

| 49. | Storage of feed and bedding | 10 | — | 1 | G | 1 | |

| Disinfection and washing department | |||||||

| 50. | Cleaning and washing equipment: | ||||||

| a) during manual washing; | 16 | 3 | 5 | G | 2 | ||

| b) when washing by machine: | |||||||

| rough cleaning room | 16 | 3 | 5 | G | 2 | ||

| washing | 16 | 5 | 6 | G | 2 | ||

| 51. | Sterilization and drying of equipment | 18 | by calculation | H | not allowed | ||

| 52. | Storage of clean cages, racks, containers, feeders, stretchers, bedding | 10 | — | 1 | G | 1 | |

| 53. | Loading food, water, and bedding into cages | 18 | — | 3 | G | 1 | |

| 54. | Temporary storage of animal carcasses | 2:4 | — | 3 | G | 3 | |

| Department for keeping experimental animals | |||||||

| Block for keeping small laboratory rodents (mice, rats, guinea pigs) in conditions that exclude the penetration of pathogenic flora8) Premises of the barrier zone. | |||||||

| 55. | Forced sanitary inspection | 25 | 3 | 5 | G | not allowed | |

| 56. | Dressing in sterile clothing: | 1 | |||||

| - clean zone | 25 | by calculation | H | » | |||

| - dirty area | 25 | » | G | » | |||

| 57. | Sterilization room with steam autoclave | 18 | » | G | » | ||

| 58. | Bactericidal hydrolock: | 18 | 3 | H | » | ||

| - clean zone | 18 | 3 | H | » | |||

| - dirty area | 18 | 3 | G | » | |||

| 59. | Germicidal airlock | 18 | by calculation | H | » | ||

| Premises of the barrier zone3) | |||||||

| 60. | Room for keeping SV&B animals and conducting experiments: | ||||||

| a) for mice | 20:22 | 15 | 10 | VERY | » | ||

| b) for rats | 18 | 15 | 10 | VERY | not allowed | ||

| c) for guinea pigs | 14:16 | 15 | 10 | VERY | » | ||

| 61. | Experiment room | 20 | VERY | » | |||

| 62. | Staff | 18 | 1 | 1 | VERY | » | |

| 63. | Warehouse for sterile equipment, feed, bedding | 18 | 1 | 1 | VERY | » | |

| 64. | Distribution and distribution of feed | 18 | 1 | 1 | VERY | » | |

| 65. | Water sterilization | 18 | 1 | 1 | VERY | » | |

| Block for keeping laboratory animals under normal conditions | |||||||

| 66. | Premises for keeping laboratory animals (except rams) | according to points 50a: 50i | |||||

| 67. | Experimentation rooms | 18 | 1 | 3 | G | 2 | |

| 68. | Surgical section premises: | ||||||

| a) preoperative with sterilization | 18 | 1 | 2,5 | H | not allowed | ||

| b) operating room, postoperative room, room for intensive care of convalescent animals | 20:22 | by calculation | VERY | — | |||

| 69. | Premises for infecting animals and working with them: | ||||||

| a) premises for toxicological studies | 18 | ||||||

| b) premises for infecting animals (handling room, boxes for control animals) | 18 | 5 | 6 | G | not allowed | ||

| c) personnel and specialists | 18 | — | 1,.5 | H | » | ||

| d) storage of clean: equipment, feed, bedding | 18 | — | 1 | G | » | ||

| e) waste collection | 10 | — | 10 | G | » | ||

| Veterinary Services Department | |||||||

| 70. | Doctor's office | 18 | 1 | 1 | H | » | |

| 71. | Sectional | 16 | 3 | 3 | G | » | |

| 72. | Laboratory diagnostics with animal autopsy box | 18 | 1 | 3 | G | » | |

| 78. | Storage of medicines | 18 | 1 | 3 | G | not allowed | |

| 74. | Isolation unit for sick animals: | ||||||

| a) patient room with airlock | according to points 50a-50i | ||||||

| b) storage of feeders, cages, equipment, storage of bedding and feed | 10 | — | 1 | G | » | ||

| c) staff | 18 | 1 | 1 | H | » | ||

| d) cleaning items with tap, drain and drying | 10 | — | 10 | G | » | ||

| Feed preparation department | |||||||

| 75. | Preparation of vegetables from the washing machine, preparation of grain mixtures | 16 | 3 | 4 | G | » | |

| 76. | Digestion hall | 16 | by calculation | » | |||

| 77. | Washing - kitchen utensils | 18 | 4 | 6 | G | » | |

| 78. | Feed sterilization | 18 | 1 | 3 | G | » | |

| 79. | Refrigerated chamber for food products | 2-4 | — | — | G | » | |

| II. General self-supporting pharmacies | |||||||

| 80. | Public service halls | 16 | 3 | 4 | G | 3 | |

| 81. | Work rooms or isolated work areas in the service hall, forwarding rooms for receiving and processing orders of an attached institution, prescription | 18 | 2 | 1 | H | 1 | |

| 82. | Assistant, aseptic, defector, walk-through gateway; blanking and filling with a sluice, sealing and control-marking sterilization-autoclave, sterilization distillation | 18 | 4 | 2 | H | 1 | |

| 83. | Packaging room, control and analytical room, washing room, sterilization solution room, distillation and sterilization room, coctorium, unpacking room | 18 | 2 | 3 | G | 1 | |

| 84. | Premises for the preparation of dosage forms under aseptic conditions | 18 | 4 | 2 | VERY | not allowed | |

| 85. | Main stock storage premises: | ||||||

| a) medicinal substances, finished medicinal products, including thermolabile and medical supplies; dressings | 18 | 2 | 3 | G | 1 | ||

| b) medicinal plant materials | 18 | 3 | 4 | G | 3 | ||

| c) mineral waters, medical glass and returnable transport containers, glasses and other optical items, auxiliary materials, clean dishes | 18 | — | 1 | G | 1 | ||

| d) poisonous drugs and drugs | 18 | — | 3 | G | 3 | ||

| 86. | Flammable and combustible liquids | 18 | — | 10 | G | 5 | |

| 87. | Disinfectants and acids, disinfection with airlock | 18 | — | 5 | G | 3 | |

| 88. | Administrative premises | according to paragraphs 13, 19, 20, 25, 26, 44 of this table | |||||

| 89. | Refrigeration machine room | 4 | — | 3 | G | 3 | |

| 90. | Electrical control room | 15 | — | 1 | |||

| SANITARY-EPIDEMIOLOGICAL STATIONS (SES) | |||||||

| Radiology group | |||||||

| 91. | Laboratory room | 18 | 3 | 5 | G | not allowed | |

| 92. | Bacteriological group Accommodation for doctors and laboratory technicians, study rooms | 18 | — | 1,5 | H | » | |

| 93. | Room for serological studies, culture, rooms for express diagnostics | 18 | 5 | 6 | G | » | |

| 94. | Boxes | 18 | 6 | 5 | H | » | |

| 95. | Preboxes | 18 | — | 10 | G | » | |

| 96. | Entomology premises for helminthological research, environmental | 18 | 5 | 6 | G | » | |

| 97. | Washing | ||||||

| a) without washing machine | 18 | 5 | 6 | G | » | ||

| b) with a washing machine | 18 | 3 | 5 | G | » | ||

| 98. | Sterilization autoclaves | 18 | — | 3 | G | not allowed | |

| 99. | Thermal rooms | As required by technology Internal air temperature is provided by technological equipment | |||||

| 100. | Rooms for registration, sorting and delivery of test results | 18 | — | 3 | G | » | |

| Virology Department and Laboratory of the Department of Particularly Dangerous Infections | |||||||

| 101. | Facilities for identification of respiratory and enteric viruses, for tissue culture preparation | ||||||

| a) working rooms of doctors and laboratory assistants | 18 | 5 | 6 | G | » | ||

| b) boxes | 18 | 5 | 6 | G | » | ||

| c) preboxes | 18 | 6 | 5 | H | » | ||

| d) boxes | 18 | 6 | 5 | H | » | ||

| e) preboxes for preparing tissue culture | 18 | — | 10 | G | » | ||

| 102. | Arbovirus identification room: | ||||||

| a) working rooms of doctors and laboratory assistants | 18 | 5 | 6 | G | not allowed | ||

| b) boxes | 18 | 5 | 6 | G | » | ||

| c) preboxes | 18 | — | 10 | G | » | ||

| 103. | Rooms for conducting bacteriological research, rooms for processing traps and preparing baits, dissection rooms | 18 | 3 | 6 | G | » | |

| 104. | Rooms for rodent infestation (bioassay) | 18 | 8 | 10 | G | » | |

| 105. | Corridors | 18 | According to the department's balance | H | » | ||

| Dairy kitchens | |||||||

| 106. | Brewhouse | 5 | By calculation | G | » | ||

| 107. | Puree making shop | 16 | 3 | H | » | ||

| 108. | Packing milk and juices | 16 | 2 | 3 | G | » | |

| 109. | Sterilization of finished products | ||||||

| a) “clean zone” | 16 | 6 | — | H | not allowed | ||

| b) “dirty zone” | 16 | — | 4 | G | » | ||

| 110. | Washing flask | 20 | 4 | 6 | G | » | |

| 111. | Taking milk | 16 | — | 1 | G | » | |

| 112. | Preparation of biolact | 16 | 12 | 12 | H | » | |

| 113. | Milk filtration and bottling room | 16 | 19 | 19 | H | » | |

| 114. | Room for heat treatment of milk and preparation of milk mixtures | 16 | 3 | 4 | G | » | |

| 115. | Cooling room | 16 | 3 | 4 | G | » | |

| 116. | Premises for the preparation of lactic acid products and lactic acid mixtures: | ||||||

| a) room for preparing sourdough starters | 16 | 3 | 4 | H | » | ||

| b) kefir workshop | 16 | 20 | 20 | H | » | ||

| c) acidophilus milk workshop | 16 | 20 | 20 | H | » | ||

| d) thermostatic | 16 | 12 | 12 | H | » | ||

| 117. | Premises for preparing and packaging cottage cheese | 16 | 3 | 4 | G | » | |

| 118. | Premises for the preparation of fruits, fruits, vegetables | 16 | 3 | 4 | G | » | |

| 119. | Premises for preparing fruit and vegetable mixtures | 16 | 12 | 12 | H | » | |

| 120. | Room for preparing fish, meat, preparing fish and meat dishes | 16 | 3 | 4 | G | » | |

| 121. | Laboratory | 18 | 2 | 3 | G | » | |

| 122. | Reception room for containers for finished products | 16 | 4 | 6 | G | » | |

| 123. | Raw materials reception room | 16 | 3 | — | G | » | |

| 124. | Washing and sterilization room | 20 | 4 inflow into the “clean” zone | 6 hood - through the “dirty” zone | G | » | |

| 125. | Kitchenware washing station | 20 | 4 | 6 | G | » | |

| 126. | Washing room: | ||||||

| a) milk pipelines | 20 | 4 | 6 | G | » | ||

| b) inventory | 20 | 4 | 6 | ||||

| 127. | Expedition, loading | 16 | 3 | — | H | » | |

| 128. | Refrigeration machine room | 16 | — | 3 | G | » | |

| 129. | Temporary storage room | 12 | — | 1 | G | » | |

| milk | periodic ventilation | ||||||

| 130. | Dry food pantry | 12 | — | 2 | H | » | |

| 131. | Pantry of vegetables and fruits | 4 | 4 (per day) | 4 (per day) | G | » | |

| 132. | Storage and reception room for containers | 12 | 4 | 6 | G | 1 | |

| 133. | Storage room for household equipment | 12 | 2 | 2 | G | » | |

| 134. | Linen room | 16 | 2 | 1 | G | » | |

| 135. | Material Pantry | 12 | — | 1 | G | » | |

| 136. | Refrigerated food waste chamber with vestibule | 2 | — | 10 | G | not allowed | |

| 137. | Service and household premises | according to section I of this table | |||||

| Donor point | |||||||

| 138. | Breast milk expressing room | 22 | — | 2 | H | » | |

| 139. | Sterilization room | 18 | — | 3 | H | » | |

| 140. | Filtration and bottling of milk | 16 | 19 | 19 | H | » | |

| 141. | Heat treatment | 16 | 3 | 4 | G | » | |

| 142. | Cooling room | 16 | 3 | 4 | H | » | |

| Milk distribution points | |||||||

| 143. | Handout | 16 | 2 | 2 | H | 1 | |

| 144. | Refrigeration chamber (for finished products) | 2 | Periodic ventilation | ||||

| 145. | Room for receiving and storing dishes from the public | 12 | — | 1 | G | 1 | |

| 146. | Cash register | 18 | — | 1 | H | » | |

| 147. | Storage room for disinfectant solutions and cleaning equipment | 16 | — | 5 | G | 3 | |

| Sauna | |||||||

| 148. | Expected | 18 | — | 3 | H | ||

| 149. | Corridor | 18 | — | 2 | H | ||

| 150. | Locker room | 22 | — | 3 | H | ||

| 151. | Shower room | 22 | — | 8 | G | ||

| 152. | Steam room10) | 100/80 (85/80) | — | 5 | G | ||

| 153. | Cooling room inside the sauna | 1 | — | 4 | G | ||

| 154. | Restroom | 26 | — | 3 | H | ||

| 155. | Massage room | 25 | — | 4 | G | ||

| 156. | Solarium | 23 | — | 3 | H | ||

| 157. | Restroom | 22 | — | 50 m3 for 1 toilet | G | ||

Source: Manual on the design of healthcare facilities (to SNiP 2.08.02-89)

Features of ventilation arrangement when zoning premises

Cafe (kitchen) ventilation systems must contain localizing devices for inflow and outlet. The recovery capacity exceeds the inflow, limiting the spread of odors.

Another scheme for organizing ventilation is mixing air flows. Here the exhaust and supply are designed in different corners of the ceiling. A colder (5 degrees) forced flow displaces the room air.

An option is used when the mechanical supply of colder air at a speed of 0.3 m/h occurs at the bottom of the room with the exhaust exiting into ventilation holes under the ceiling.

Air exchange rate in preschool premises

| Premises | t° (C) - not lower | Air exchange rate per hour | |||

| In IA, B, D climatic regions | In other climatic regions | ||||

| influx | hood | influx | hood | ||

| Reception rooms, play nursery group cells | 22-24 | 2,5 | 1,5 | — | 1,5 |

| Reception, gaming junior, middle, senior group cells | 21-23 | 2,5 | 1,5 | — | 1,5 |

| Bedrooms of all group cells | 19-20 | 2,5 | 1,5 | — | 1,5 |

| Nursery toilets | 22-24 | — | 1,5 | — | 1,5 |

| Toilet facilities for preschool groups | 19-20 | 2,5 | 1,5 | — | 1,5 |

| Medical premises | 22-24 | 2,5 | 1,5 | — | 1,5 |

| Halls for music. and gymnastics classes | 19-20 | 2,5 | 1,5 | — | 1,5 |

| Walking verandas | at least 12 | according to calculation, but not less than 20 m3 per 1 child | |||

| Hall with swimming pool bath | at least 29 | ||||

| Changing room with shower pool | 25-26 | ||||

| Heated passages | at least 15 | ||||

Source: Sanitary and epidemiological rules and regulations SanPiN 2.4.1.3049-13. Appendix 3

Ventilation design: Exhaust hoods

The operating principle of local exhaust hoods is based on taking into account the natural pressure that forces hot, polluted air to rise upward, and on creating additional vacuum for this air to enter the air duct. The polluted air collected in the umbrella passes through filters, varying depending on the degree of contamination and oil content, and is fed into a network of air ducts. Exhaust hoods vary in shape and purpose. The USA has quite a lot of experience in designing ventilation systems for industrial kitchens. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) standard classifies hoods into two classes. The first class includes umbrellas installed to localize hot air flows with oil particles. Therefore, these umbrellas have oil filters and are installed directly above the cooking surface. Second class exhaust hoods are installed above the stoves to remove relatively clean heated air that does not contain oil particles. An important point in the classification is that when using umbrellas of the first class, the presence of a fire protection system is required, and the second class does not provide for the installation of this system. According to their location and structural characteristics, umbrellas are divided into two types: shelf and hinged. Shelf-type umbrellas are attached to the wall at a close distance from the surface on which food is prepared. Umbrellas of this type are not advisable to use in places with a high content of oil particles in hot air; they are recommended to be installed in low areas of kitchens. Canopy-type umbrellas are installed above food preparation surfaces in the form of shelters that collect polluted air. Umbrellas of this type are preferably used for extracting air with a high content of oil vapors and polluting particles. Hinged umbrellas are divided into three subgroups: wall-mounted, single island and paired island. Wall-mounted hoods generally have lower exhaust air flow rates in areas where there is a wall next to the cooking surface. Island-type umbrellas are best used in rooms with a small area and installed above a cooking surface located in the middle of the room. Ventilation design: Dimensions of exhaust hoods To increase the efficiency of removing contaminated hot air from food preparation surfaces when designing kitchen ventilation, it is necessary to correctly select the dimensions of the hoods and their correct installation. As a rule, the dimensions of the umbrella should be larger than the size of the cooking surface, by about 15 cm, due to the fact that the air flow rising from the cooking surface expands. In some cases, shelf-type umbrellas may be smaller than the cooking surface, and the difference to the true side should not exceed 25 cm. An important factor when designing ventilation is the installation height of exhaust hoods. Shelf-type umbrellas are mainly placed at a height of 45-60 cm. At a lower height of the umbrella, there is a possibility of oil particles with a temperature of more than 100 °C sticking to the filter. At higher altitudes, the efficiency of suction of exhaust air is lost. The average installation height of canopy-type umbrellas is approximately 100-120 cm. To increase the efficiency of umbrellas of this type, edge curtains are sometimes used, due to which the “suction” of air from the sides is reduced and the speed of air flow is increased. Ventilation design: Oil filters for exhaust hoods Oil filters installed in exhaust hoods that remove air containing oil particles are used to prevent the penetration of these particles into the air duct network and to clean the exhaust air. The operation of oil filters is based on the principle of sifting out oil particles by centrifugal force, which is created by special plates. The effectiveness of cleaning depends on the design of the cooking equipment over which the hood is installed, as well as on the air flow rate, air temperature and filter design. In each of the umbrellas, depending on the design, there are two or more sets of plates made of steel, stainless steel or aluminum. The plates can be permanently attached or removable. The removable plates are easy to clean - in the dishwasher or under running tap water. To wash the permanently attached plates, the washing system tips installed in the umbrellas, which contain detergent, are used. As a rule, in filters with permanently attached plates, an automatic cleaning system is activated at the end of each working day: the filters are washed at a temperature of 60-80 ° C and a pressure of 2-5 bar. The automatic cleaning system can be combined with the fire protection system. To ensure effective retention of oil particles by oil filters in the ventilation design, the speed of air passage through the filter should be in the range of 0.8-1.5 m/s. Oil filters are located at an angle of 45-60° - in this position, the possibility of collected particles falling back onto the cooking surface is eliminated. The surface temperature of oil filters should not exceed 100 °C. At higher temperatures, the oil particles deposited on the filter partially evaporate and penetrate into the air duct, while the rest settle on the plates and form a crust on them.