A private house or cottage is rebuilt, improved, and equipped throughout its entire lifespan. Sometimes these manipulations are forced, due to wear and tear of a structure or system, and sometimes there is a desire to modernize them to increase comfort in the house. But, no matter what the reasons lie behind the process, sometimes an operation such as inserting into a pipe without welding becomes relevant. For example, without this procedure it is impossible to organize an additional sewer drain when installing a washing machine or, conversely, to create an additional water collection point to connect a household appliance to the water supply system.

Methods of cutting into sewers

The sewer pipe to which the plumbing equipment is connected can be located vertically or horizontally. Methods of cutting in with different line locations at 110 mm. are no different; they are divided into main types: correct and incorrect.

The right way

To carry out work in a plastic pipeline, standard plumbing parts are used: tees, regular and expansion couplings. The method consists of the following operations:

- Measure the length of the riser, which must be cut taking into account the dimensions of the mounted parts. It should be equal to the size of the tee and expansion coupling, taking into account the depth of the mounting sockets.

- The pipe is cut in the right places, its outer and inner edges are protected.

- Coat all parts with silicone grease and insert them into the cut in a certain order. There are several installation options:

- The tee, which is used to insert into the system, is fixed in the following way: the lower part of the tee is connected to the riser with an adapter coupling with rubber sealing rings, the upper part is secured with a compensation coupling. This technology is used for installation in vertical risers.

- With the second method, the outlet is located in the compensator itself, and there is no need to use an extra part in the form of a tee. Typically, the lead is located at an angle of 45 degrees to the center line of the compensator - this allows this method to be effectively used for cutting into horizontal sections.

Rice. 4 The main parts for correct tapping are an oblique bend, a tee, an expansion joint and a coupling

The correct method can be connected to a 110mm line. pipes that match in size or 50 mm bends.

In the case of steel or cast iron sewer pipes, they are shortened to fit the tee for insertion, which is then welded to the break point with a welding machine.

Wrong way

This technique is designed for cutting into an existing sewer line without completely cutting the pipeline, but using cutting, when a hole of the required diameter is made in the pipe.

Then the outlet pipe is placed over the cut hole and its body is secured. When carrying out work, special adapters or saddles are used, through which the sewer line is connected to the outlets of plumbing fixtures.

When can you do without soldering?

Craftsmen have to look for an answer to the question of how to cut into a polypropylene pipe without soldering in several cases. Firstly, not everyone has such a device “lying around” in their household. But you are either reluctant to search through friends, rent or buy welding equipment, or don’t have the time/opportunity. Sometimes tapping into a PP pipe without a special device can be considered the optimal way, which is why even experienced craftsmen do this. This decision is consciously made in several cases:

- when installing temporary pipelines;

- when there are only a couple of joints to be connected;

- after purchasing meters or additional plumbing fixtures;

- if you need to quickly replace a section of the pipeline where a defect has appeared;

- when work with polypropylene pipes is carried out on a system where the hydraulic load is low, the first example is sewerage.

An alternative installation method may be required in one more case: when it becomes necessary to make the connection detachable, so that there is a chance to disassemble the area from time to time for maintenance.

How the insertion is made

Let us note right away that unauthorized access to communications is classified as illegal activity. Responsibility for illegal tapping into a water supply system is a fine of 3 to 4 thousand rubles; sometimes water utility workers, when a violation is discovered, calculate much larger amounts to be paid, but this is illegal, and the court must decide on the amount.

Regarding the specifics of the work, you must have all the necessary documents on hand, from the design to the permit approved by the relevant organization. The work itself differs depending on the material used to make the pipe.

Cast iron

As for this option, insertion into a cast iron water supply system is carried out in the following sequence:

The branch site is cleared of dirt, the protective coating must be removed from it and the rust must be cleaned off

This is very important as corrosion after the saddle is put on can destroy the connection over time.

Next, in the place where the hole will be made, it is recommended to remove the top hardened layer of material using an angle grinder. This will significantly speed up and simplify further drilling

Although some modern versions of drilling equipment are so durable that this type of work can not be performed.

The next stage is the installation of a special saddle, which is a clamp for pipes. To prevent leaks, a special rubber seal is placed between the structure and the pipe; it is very important to position it correctly so that the holes in the clamp and the rubber gasket coincide.

It is better to choose saddles made of plastic - they are not damaged by corrosion and retain their properties for more than half a century

A shut-off valve is installed on the structure, through which a special crown is inserted, with which the drilling is performed. It is equipped with carbide tips and is specially designed for working with cast iron.

After completion of work, the valve is closed and the device is removed from the system.

It is important to do everything as quickly and carefully as possible so that as little water spills as possible.

Such devices can work with any type of pipes

Steel

Regarding this material, the following can be said:

Inserting a water supply into existing networks is carried out in approximately the same way as with cast iron pipes, but if it is possible to shut off the water supply while the work is being carried out, then you can use another option, and this is what we will pay attention to.

First of all, the surface is cleaned of contaminants and treated with a grinder or drill with a wire attachment to remove corrosion. This is necessary in order to ensure maximum connection security.

Next, a hole is marked in the main line, which is cut out as carefully and accurately as possible.

After everything is prepared

a pipe is attached, which will serve as an outlet, and welded to the pipeline. After completion of the work, the seam is carefully inspected and, if necessary, welded.

It is important that the seam is secure

Lastly, a shut-off valve is screwed or welded to the outlet and the entire connection is treated with an anti-corrosion compound.

HDPE pipes

This option differs in that insertion into an existing water supply system is carried out without welding or other similar work.

The instructions for carrying out the work are as follows:

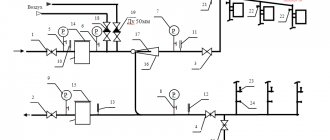

The diameter of the passing water supply is determined and a special fitting is purchased - a clamping coupling, with the help of which the connection will be made. In the diagram below you can see how this element is fastened; everything is done quite quickly and simply.

Tapping under pressure into a water supply system is done very quickly, since there are a number of special units specifically designed for this purpose

After securing the coupling, a special device for drilling holes is placed on it, which is hermetically fixed to the valve

When drilling is finished, it is very important to remove the drilling unit as quickly as possible, while simultaneously turning off the water so as not to flood everything around

After insertion, the material does not require additional protective treatment, which can also be considered an important advantage.

We advise you to carefully approach the choice of contractor and control the process. As you can see, there is nothing complicated in the sidebar, and anyone can understand the topic.

Methods

Often the material of the water supply pipeline determines both the material of the branch line pipe and the insertion method. If the central or secondary pipe is steel, then it is also better to use a steel pipe. As a last resort, make a transition section in the form of a fitting made of a steel pipe with a valve, to which then connect a pipeline made of another material.

Tapping of steel pipes is done in two ways:

- using a welding machine by welding a fitting to the water supply;

- using a steel clamp without welding.

Both methods are used both when tapping into a pipeline that is under pressure and without pressure. But on high-pressure pipelines, welding is recommended to be used only in emergency, emergency cases, as well as when organizing additional safety equipment. In the normal mode of work, actions are required to completely shut off the section of the water pipeline where the tie-in is made using welding.

The algorithm for working with welding on an existing pipeline is as follows:

- a hole is dug with an excavator to a level above the laid pipeline of approximately 50 cm;

- the section of pipe into which the insertion is planned is manually cleared of soil;

- the insertion site is cleared of anti-corrosion coating and other protective layers, and the specific area of connection of the fitting or branch pipeline is cleaned to shiny metal;

- the fitting is welded to the tap;

- after the metal heated by welding has cooled, a drill is inserted into the fitting through the tap and a hole is drilled in the wall of the water supply;

- when water flows through the fitting, the drill is removed and the tap is closed (the insertion is completed, further laying of the water supply line begins from the valve on the fitting).

A mortise clamp is a simple piece consisting of two halves of semicircular shapes. These halves are put on the pipe and tightened together with bolts and nuts. They differ from ordinary clamps only in the presence of a threaded hole on one of the metal parts. A fitting is inserted into this hole, serving as part of the outlet line. The hole for the pipe can be located anywhere in the water supply system, and when screwing in the fitting, it will always be at right angles to the linear plane of the pipeline surface.

The rest of the process is similar to tapping using welding: a drill is inserted into the fitting through a tap and a hole is drilled. If the tap is of small diameter and the pressure in the water supply is within 3–4 kgf/cm², then the tap can be screwed on without any problems even after drilling (if it is threaded and not welded). Additional lines are also connected to the cast iron main using clamps.

Welding cannot be used due to the low ductility of cast iron, because it can crack in areas of overheating.

Insertion into pipes made of plastic or polyethylene occurs using plastic clamps or saddles (half-clamp with fasteners). Clamps and saddles can be simple or welded. Working with simple devices is not much different from inserting a clamp into a steel pipe. And welded saddles or clamps contain all the equipment necessary for welding. This saddle assembly is installed on the pipe in the intended location, the terminals are connected to electricity, and after a few minutes the insertion will be automatically completed.

How to tap into a water pipe

The technology for arranging a pressure outlet from the main involves three stages of implementation:

Excavation

– digging a pit with dimensions of 150x150 centimeters, the bottom of which drops 0.5 meters below the pipe. In this case, the first meters of soil are covered with the help of an excavator. And only when they reach the depth of the pipeline do they switch to shovels. The marker for this mark is a polymer or metal tape laid at a distance of 30-50 centimeters above the pipe. If the puncture point is in the caisson (well), then the excavation stage can be eliminated.

In addition to the pit around the main line, you need to build a trench for supplying water supply to the house. Its width cannot be less than 50 centimeters, and its depth cannot be below the freezing level of the soil.

Insertion into main- type water supply pipe

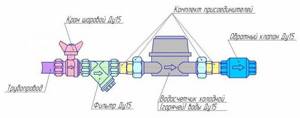

- carried out by piercing the reinforcement body through a hole in an overhead fitting - a saddle or a collapsible clamp. This mating element is similar to a regular tee, divided into two halves. Moreover, it is necessary to screw a special shut-off valve onto the side outlet of the saddle, blocking the flow of water after the body of the pipeline is punctured.

Polymer pipeline

The puncture technique depends on the type of structural material of the pipe fittings. For example, inserting into a cast iron water supply is preceded by grinding the hardened outer layer. Having removed the compacted layer, you install a dismountable saddle on the insertion point, sealing the contact point with rubber pads, and drill the pipe body with a carbide bit. Insertion into a polymer pipe is carried out according to the same scheme, only without grinding.

The crown for polymer reinforcement can be of any kind, but the cutting tool for a cast iron pipeline must be made only of carbide material. In this case, during the process of cutting into cast iron, you will have to change the crowns at least 3-4 times.

Arrangement of a water supply line from the main to the house - this stage involves laying a pipeline from the main to the foundation. The new water supply starts from the saddle valve and ends with the water flow meter in the house.

The best fitting option for a new water supply line would be a polyethylene pipe. It is not afraid of temperature deformation, does not rot or rust.

After completing all the work, all you have to do is fill up the trench and foundation pit above the insertion point. However, if you want to simplify the operation of the outlet, then you will have to build a caisson (well) above the insertion point.

Well for connection to the main line

To do this you need to do the following:

- Deepen the pit by 50-70 centimeters and add a 20-centimeter gravel cushion in place of the selected soil.

- Roll out the roofing material over the gravel and pour a 10-centimeter concrete slab reinforced with a lattice of 4-mm reinforcement.

- After 3-4 days, when the concrete has strengthened to 70 percent strength, build a “shaft” of foundation blocks above the slab, raising its neck to zero level. The shape of the shaft can be either round or square.

- Place a cast plate with a round hole for the hatch on the neck of the shaft.

- Provide vertical waterproofing of the outer walls of the shaft using a coating compound.

- Fill the pit with selected soil.

As you can see: the construction of a caisson requires a fairly impressive investment of time, effort and money. Therefore, inserting a water supply into a well is always cheaper than diverting it from an underground section of the main.

Approximate cost of work

Connecting a private household to the main water supply network is the most labor-intensive and financially expensive process. The cost of work depends on the distance to the well, the volume of excavation work, and the price level for services in the region.

The approximate figures are as follows:

- obtaining technical specifications and other documents, approval – 22 thousand rubles;

- costs for pipes and other network elements – 9-10 thousand;

- fee for connection to the central network and work on inserting into the highway - from 20 to 50 thousand;

- earthworks – up to 10 thousand;

- complex work on laying a network - 2-2.5 thousand per 1 meter.

Thus, the total cost can range from 80 to 115 thousand rubles.

We make a tap into a water supply system under pressure with our own hands

When building an individual house, cottage or country house, owners provide for the possibility of providing a residential building with water supply. The most optimal solution would be to connect to an existing water supply system located next to the property.

Typically, the main pipeline is laid along central streets, and for tapping it requires the appropriate permission from the water utility and the preparation of technical documents, since unauthorized connection entails penalties. But if you previously installed a valve that has failed and needs to be replaced, or you have permission and you can cut it in yourself, then with certain knowledge and the availability of tools, you can connect the water supply yourself.

Installation of a drain pipe without blocking the main line

Tapping technology without changing pressure is an efficient and productive technique. But before you do it, you need to consider:

- dismantling insulation and protecting the surface in the area where the pipe is drilled. In this case, the diameter of the material with which water will be drained is less than the parameters of the main pipe;

- fixation of additional network elements. A valve with a device for making holes is fixed to the flange;

- if a steel product is used, then the clamp is replaced with a pipe that is welded. A valve with a cutter is attached to it. The completed seam is additionally welded;

- At the next stage, a cutter of the required size is installed. If the hole is ready, the cutter is removed;

- closing the valve. If the insertion is completed, it is necessary to restore the anti-corrosion coating and insulate the pipes.

Step-by-step introduction to the internal network

If it is necessary to cut into an old steel pipeline, then the main method is to arrange a branch by welding a tee. This will require a large amount of work.

If a pipe made of plastic or its derivatives is connected to the main line, then you will need to cut out a section of the pipe taking into account the size of the tee being mounted. But when performing such work, inconvenience arises due to the close distance between the network and the wall of the building.

A simpler method of installing a branch is to insert a pipe with a curved flange. A consumable with a pipe whose diameter corresponds to the pipeline dimensions is preliminarily rejected. The section is cut lengthwise so that its part with the pipe fits tightly onto the pipeline as its other wall.

The previous blank is placed on the pipe with the hole. The fixation site is treated with sealant. The resulting flange is tightened with 2 clamps on the sides relative to the pipe. Subsequently, the remaining part of the network is fixed to the pipe.

On the modern plumbing market you can buy adapters, special saddles and other devices with which the insertion is made (regardless of the conditions for laying the network).

If a saddle is used, the pressure in the system does not change. A saddle is a clamp made of 2 parts. Using bolts, these parts tightly compress the consumable on both sides. The tap is fixed to the saddle using a special connection.

If the diameter of the hole is no more than 1/3 of the diameter of the pipe, then it is drilled with a special device. He joins the tap in time. If the hole is ready, the tap is closed and the device is dismantled. An outlet pipe is mounted to the installed tap.

To connect the house, a saddle with a valve and a built-in cutter is used. For its installation you will need sleeve welding. A similar product is used for pipelines whose pressure does not exceed 16 bar. During installation, the line is not blocked, and when drilling pipes there is no leakage and no chips are formed. The connection does not corrode and has been in use for more than 50 years.

The essence of the process

To connect the outlet to the main pipe, you need to drill a hole in it and attach the outlet pipe using soldering or various types of fittings.

If it is impossible to turn off the water supply, the hole and connection are made using special clamps.

During the operation, two general conditions must be met:

- the diameter of the drill and the diameter inside the outlet pipe must match;

- The additional pipe is smaller in diameter than the main one.

Features of tapping into water supply systems made of metal, cast iron and plastic

In order to cut into a metal pipeline, use a saddle clamp with drilling:

- Before you begin installing the device on the pipe, it must be thoroughly cleaned of dirt (if any) and rust. In addition to the lower part, which has the shape of a semicircle, in the upper part of the clamp there is a valve with a hole for drilling directly under the drill. After the clamp is installed on the pipe, its parts are connected to each other with bolts.

- After the clamp is secured, a hole is drilled and closed with a plug using a special screw. This clamp can be used as a shut-off valve. You can also use a clamp with an already installed valve. Once the hole is ready, the drill is pulled out and the valve is closed. After which other necessary installation work is carried out.

- A special machine can be attached to a metal clamp, which consists of a handle with a ratchet, a locking bolt, a shaft with a drill at the end and a flushing tap. Everything is contained in a metal case, which is attached to the clamp using rubber seals. Due to the fact that there is a guide sleeve, you can drill in a certain direction. In this way, an insertion is made into a water pipe made of cast iron or steel.

Insertion into a plastic pipeline without reducing the pressure on it is possible using an electric-welded saddle clamp. It is made of special plastic and has a heating coil with a drilling mechanism. There is a bar code on the body of this clamp, which allows you to enter welding characteristics with the required accuracy.

- The pipe must be cleaned in advance and a clamp must be attached to it using bolts, which has terminals for connecting a welding machine.

- Using a welding machine, the spiral is heated and the outlet is welded.

- Nowadays, a saddle with a built-in cutter and valve is most often used. In order to make an insert into the water supply using welding, use a coupling.

- After everything has cooled completely, after an hour you need to use a cutter to make a hole and screw on the shut-off valve.

This method is applicable for pipelines with pressures up to 1.6 MPa.

In order to drill a cast iron pipe under pressure, clamps are used that have a special design and bimetallic crowns. In this case, the crown should not overheat, and work should be carried out at low speeds.

Stages of work when inserting a water pipe into a cast iron pipe:

- it is necessary to excavate the pipe and clean it from rust at the insertion point;

- using a grinder, cut off the top layer of hot cast iron;

- install a collapsible saddle; in order to seal the joint between the fittings and the clamp, it is necessary to put a rubber seal;

- the shut-off valve must be attached to the flange outlet, through which a crown (cutting tool) will be inserted;

- drill a cast iron pipe, cooling the cut area;

- the crown is removed from the valve and the water flow is stopped.

The pipe is drilled with a carbide crown, which will need to be changed at least 3-4 times during the entire process. Also, do not forget that it is necessary to ensure that the saddle pipe has a slope of 2 degrees towards the house.

To tap into a cast iron pipe, you need to use drills designed for working with metal!

Welding installation of a pipe to a steel water supply should only be done by qualified specialists. Installation of saddles on a cast iron or polymer pipeline is done independently, but for this it is necessary to turn off the water supply. Tapping under pressure must be carried out taking into account all the rules and recommendations, otherwise this work may pose a danger to health and material assets.

If you live in a house outside the city, then you need to arrange a water supply to your home, and to solve this issue there are two solutions - get your own well or well, or connect to a centralized line with high-pressure water. The first option is expensive, time-consuming and labor-intensive. The second solution will provide your home with water for one day, but you will be dependent on the water supply schedule (this happens in remote peripheral villages).

The positive aspect that the connection to the water supply gives is that you will receive stable pressure in the pipes, which will ensure the same stable operation of household appliances that require water supply - an automatic washing machine, dishwasher, plumbing equipment - a bathtub, a jacuzzi, a shower or even a swimming pool.

Plumbing clamps for fastening

They are made in the form of a bracket into which the pipe is clamped. Most often they are made of carbon steel with an anti-corrosion coating. This is usually a coating of chromium, nickel or zinc. The pipe clamp has reliable clamping elements, which are screw worm mechanisms, tape clamps or bolts with nuts of the appropriate size.

A reinforced clamp is used with heavy loads, when additional equipment is hung on the system or the pipes themselves are heavy. It is made by stamping with galvanic galvanizing. Plumbing clamps with a special rubber gasket are recommended for use where the system operates under vibration conditions. The gasket will not only dampen vibrations, but also provide sound insulation.

Types of clamps

Clamps come in various designs and configurations. The most popular are:

- clamp-clip;

- saddle clamp;

- drill clamp;

- electric welded clamp saddle.

The use of a clamp-clip is possible for inserting into a water main that is not under pressure. Structurally, it consists of a pair of parts, one of which has a threaded outlet. The clamp is clamped with bolts and can be made of plastic or metal.

For cutting under pressure into a pipe made of metal, asbestos cement or plastic, a saddle clamp is used. It is attached to the pipeline using a bracket. Often, such a clamp is made of metal and has a locking plate or a special mechanism.

The drilling clamp is used for cutting into a pipe under pressure. In addition, it can come with attachments, as well as rotary connectors. To install the clamp on steel, cast iron and plastic pipes, special equipment is required.

The design of the drilling clamp includes a rotary-bolt mechanism. Subsequently, it is applicable as a shut-off or control valve.

The clamp for tapping is selected depending on the purpose of the outlet and the material of the main pipe

The saddle clamp is used for inserting into a plastic pipeline. The design includes a cutter for making a hole and a heating coil. The body of such a clamp is made of special plastic and additional equipment is required for its installation.

Insertion into different types of pipes: plastic, steel and cast iron

Plastic pipes

Increasingly, metal pipes are being replaced by polyethylene. Polyethylene analogues can be found in external and internal utility networks, water supply systems, sewer and drainage systems, and gas pipelines. At the same time, the fittings for such systems are being improved.

Cast electric welded products

For example, prefabricated ones are being replaced by cast electric-welded fittings, which differ:

- high strength;

- resistance to water hammer;

- good flexibility, which helps prevent highways from breaking, for example, when the soil moves;

- high chemical resistance;

- lack of roughness, which ensures the absence of deposits on the reinforcement.

The problem often arises of how to insert the required pipeline element into an operating plastic line. A saddle for cutting under pressure into a polyethylene pipe is well suited for this, thanks to which such a technical operation will take place efficiently, quickly and reliably. By the way, it is the same as the saddle for cutting under pressure into a plastic pipe.

Using an electric-welded HDPE saddle for tapping under pressure, branches of pipelines are connected through which drinking and sanitary water, flammable and inert gases are transported and distributed.

Important! A saddle for polyethylene pipes is used when there is a special welding machine powered by electricity.

Steel pipes

Thanks to the use of saddles, you can crash into any functioning communication without disconnecting it. The saddle for tapping under pressure into a steel pipe can be welded or compression.

The electric welded steel saddle for tapping under pressure allows for the welding of an overhead clamp. But installing compression fittings is considered a simpler option.

Cast iron pipes

Typically, a compression-type saddle is used for tapping under pressure into a cast iron pipe.

Compression saddle

It is different:

- practicality;

- low cost;

- speed of installation.

The main disadvantage: the compression saddle is less reliable than the electric welded saddle for tapping under pressure of elist, with which you can easily cut into the highway.

A typical compression fitting is a pressure tap saddle with a mating part.

It is clear from the design that the mating part of the fitting includes a press-fit sleeve and a cover-nut.

Modern saddles

The electric welded saddle 110x063 sdr 11 fox for tapping under pressure has the form of an overlay pipe with an open spiral, which ensures optimal heat transfer. On the sides, as well as in the center, the part is equipped with cold zones, thanks to which the molten mass does not flow out. To ensure automatic welding, a bar code is applied to the fittings. You can buy a saddle for tapping under pressure at any specialized store. The price of a saddle for pressure tapping depends on the manufacturer.

Electric welded saddle

The valve for tapping under pressure, Frialen, is very popular among shut-off valves; its design provides for the presence of an elongated outlet pipe. Fittings are fairly compact products without threaded connections and with a drive spindle, for the production of which high-density low-density polyethylene is used.

The frialen pressure tapping valve is equipped with an integrated cutter drill with upper and lower stops that can be easily moved inside the metal sleeve. It is used in gas pipelines with pressure up to 10 atmospheres and water pipelines designed for pressure up to 16 atmospheres. The price for a valve for tapping under pressure is approximately from 11,700 rubles.

This element of the frialen pipeline is usually installed at a depth of no more than 2m70cm. The valve is controlled by a special telescopic mounting kit for valves. The design has an outlet pipe the length of which is designed approximately for 2 welds. The telescopic design allows you to control the valve from a hatch located outside. The lower part of the part is equipped with an open heating element, with which it is easily welded to the pipe.

Video

Which solution is better?

If possible, welding is better. Does it make sense to use a solderless alternative? Yes, it is possible that such a connection will not cause problems for several years, especially in systems without pressure or in cold water pipelines. Many people consider the best way to use clamps. But for apartments, even this option is still advised not to be considered.

Replacing saddles (with the traditional welding of a normal tee) is recommended by the vast majority of craftsmen who come on call. Even if the owners discovered the problem in a completely different place.

How to cut into a polypropylene pipe without soldering? The following video explains one potential method:

Video loading...

How to repair a fistula in a pipe

How to repair a fistula in a pipe. Sometimes a situation occurs that a fistula appears in an iron pipe of a water supply or heating riser. This is especially common in hot water risers. The first signs that a pipe will soon burst is when a red growth appears on it, but it may not appear.

In scientific terms it is called pitting corrosion, but in simple terms it is “Pipe” to a pipe. Fistulas appear on the pipe, either due to wear or due to stray currents.

In principle, when you get a fistula, you won’t care why it appeared, you will have a question: how to fix it quickly? I'll try to describe a couple of options on how to do this.